Abstract

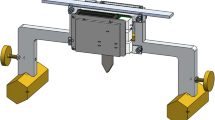

A Herbert pendulum wasmodified to a lightweight pendulum with a cylindrical indenter by Habara in order to measure the hardness of viscoelastic materials such as plastics and rubbers. It is difficult to provide enough strain to evaluate the hardness of hard materials using the Herbert pendulum with a cylindrical indenter because the contact stress between the indenter and the specimen is smaller than that of the original Herbert pendulum. In this study, a modified measurement system is developed to accurately measure the swing angle of a lightweight Herbert pendulum with a cylindrical indenter. Two independent laser displacement meters are installed, to provide a noncontact measurement of the swing angle. The modified Herbert pendulum with a cylindrical indenter is evaluated for measuring the hardness of metals. Four types of Herbert hardness are compared with the Vickers hardness. Good correlation is shown between the damping hardness (one type of Herbert hardness) and the Vickers hardness. The damping hardness measured based on the modified Herbert hardness tester can be used as the hardness parameter of the metals.

Similar content being viewed by others

References

Sonmez, F.O., and Demir, A., “Analytical Relations between Hardness and Strain for Cold Formed Parts,” Journal of Materials Processing Technology 186:163–173 (2007).

Yamagiwa, K., Watanabe, Y., Matsuda, K., Fukui, Y., and Kapranos, P., “Characteristics of a Near-Net-Shape Formed Al–Al3Fe Eco-Functionally Graded Material Produced over Its Eutectic Melting Temperature,” Materials Science and Engineering A416:80–91 (2006).

Herbert, E.G., “Some Recent Developments in Hardness Testing,” The Engineer 135:686–687 (1923).

Mamada, S., “Hardness Test of Wood by a Pendulous Friction Apparatus (in Japanese),” Bulletin of the Tokyo University Forests 49:205–215 (1955).

Kalaee, M., Akhlaghi, S., Nouri, A., et al., “Effect of Nano-Sized Calcium Carbonate on Cure Kinetics and Properties of Polyester/Epoxy Blend Powder Coatings,” Progress in Organic Coatings 71:173–180 (2011).

Benedicks, C., and Christiansen, V., “Investigations on the Herbert Pendulum Hardness Tester,” Journal Iron and Steel Institute 110:219–248 (1924).

Matsubara, M., and Sakamoto, K., “Modified Herbert Hardness Tester”, Proceedings of the SEM Annual Conference, Albuquerque, NM (2009).

Habara, H., Kawamitsu, T., Harimoto, K., and Inoue, H., “Restoration of the Herbert Pendulum Hardness Tester and Its Application (in Japanese),” Journal of Material Testing Research Association of Japan 43(4): 248–254 (1998).

Matsubara, M., and Skamoto, K., “Improved Herbert Hardness Tester,” Experimental Techniques 36(3): 1–4 (2012).

Metallic Material Database, URL http://metallicmaterials.nims.go.jp/metal/view/testResultList.html?id=1849347387_tr92 [accessed 29 November 2013].

Metallic Material Database, URL http://metallicmaterials.nims.go.jp/metal/view/testResultList.html?id=1849347387_tr117 [accessed 29 November 2013].

Metallic Material Database, URL http://metallicmaterials.nims.go.jp/metal/view/testResultList.html?id=1849347387_tr280 [accessed 29 November 2013].

Metallic Material Database, URL http://metallicmaterials.nims.go.jp/metal/view/testResultList.html?id=1849347387_tr229 [accessed 29 November 2013].

Metallic Material Database, URL http://metallicmaterials.nims.go.jp/metal/view/testResultList.html?id=1849347387_tr330 [accessed 29 November 2013].

Metallic Material Database, URL http://metallicmaterials.nims.go.jp/metal/view/testResultList.html?id=1849347387_tr318 [accessed 29 November 2013].

Kuwabara, T., Kuroda, M., Tvergaard, V., and Nomura, K., “Use of Abrupt Strain Path Change for Determining Subsequent Yield Surface: Experimental Study with Metal Sheets,” Acta Materialia 48:2071–2079 (2000).

Kacem, A., Krichen, A., Manach, P.Y., Thuillier, S., and Yoon, J.W., “Failure Prediction in the Hole-Flanging Process of Aluminium Alloys,” Engineering Fracture Mechanics 99:251–265 (2013).

Lee, Y.-H., Ji, W.-j., and Kwon, D., “Stress Measurement of SS400 Steel Beam using the Continuous Indentation Technique,” Experimental Mechanics 44(1): 55–61 (2004).

Imanaka, M., Ishikawa, R., Sakurai, Y., and Ochi, K., “Measurement of Strain Distributions Near the Steel/Epoxy Interface by Micro-Raman Spectroscopy under Tensile Load Condition,” Journal of Materials Science 44:976–984 (2009).

Cahoon, J.R., Broughton, W.H., and Kutzak, A.R., “The Determination of Yield Strength from Hardness Measurements,” Metallurgical Transactions 2:1971–1979 (1980).

Fox, P.G., and Freeman, I.B., “What Does the Pendulum Hardness Test Measure?,” Journal of Materials Science 14(1): 151–158 (1979).

Zaima, S., and Naito, I., “An Investigation on the Aging of the Aluminium Alloy by Measuring the Damping Capacity,” Reports of the Faculty of Engineering, Yamanashi University 12:33–38 (1961).

Hishitani, K., Sasaki, M., Imai, D., Kogo, Y., Urahashi, N., and Igata, N., “Internal Friction of TiNi Alloys Produced by a Lamination Process,” Journal of Alloys and Compounds 333(1–2): 159–164 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suzuki, R., Kaburagi, T., Matsubara, M. et al. Hardness Measurement for Metals Using Lightweight Herbert Pendulum Hardness Tester With Cylindrical Indenter. Exp Tech 40, 795–802 (2016). https://doi.org/10.1007/s40799-016-0080-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-016-0080-2