Abstract

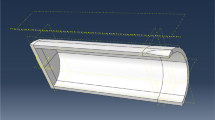

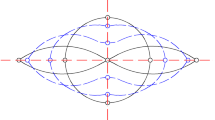

The plastic collapse behavior and strength were investigated for an austenitic stainless steel pipe with two 90° through-wall notches perpendicular to the pipe axis direction. Double-notch specimens with various notch separation distances were coated with photo-plastic film. Arbitrary combined axial tensile and bending loads were applied to the specimens. Changes in the photoplastic fringe pattern were observed during the tests to investigate the plastic collapse behavior. The plastic collapse strength was evaluated using a model based on an elastic-perfectly plastic body. The photo-plastic fringe patterns at the experimental plastic collapse point differed based on the loading history. Thus, the plastic collapse behavior depends on the loading history. In addition, the plastic collapse strength differed based on the loading history and hardly depended on the notch separation distance. The experimental plastic collapse occurred before reaching the theoretical plastic point for only some pure tension loading tests. Thus, the model analysis based on an elastic-perfectly plastic body used in this study might give an unconservative estimate for the plastic collapse of a stainless steel pipe subjected to a pure tension load.

Similar content being viewed by others

References

Matsubara, M., “A Parametric Study on J-integral Under Pressurized Thermal Shock by Using Statically Indeterminate Fracture Mechanics,” Nuclear Engineering and Design 196: 153–159 (2000).

Okamura, H., Takano, T., and Watanabe, K., “Application of Fracture Mechanics to the Analysis of Statically Indeterminate Structure,” Mechanical Behavior of Materials 1: 245–255 (1972).

Okamura, H., Watanabe, K., and Takano, T., “Deformation and Strength of Cracked Member under Bending Moment and Axial Force,” Engineering Fracture Mechanics 7: 531–539 (1975).

Hasegawa, K., Kobayashi, H. “Failure Stresses For Pipes With Multiple Circumferential Flaws,” Proceedings of SEM 2004, PVP 2004–2712:351–355 (2004).

Matsubara, M., Izawa, S., Hirao, N., Busujima, K., Koyama, T., Machida, K., Kawada, D., Ohta, A., Harizuka, H. “Development of Testing Equipment for Studying Statically Indeterminate Fracture Mechanics,” Proceedings of SEM 2005 Annual Conference and Exposition on Experimental and Applied Mechanics. Annual Conference was held in Portland (2005).

Izawa, S., Matsubara, M., Nezu, K., and Sakamoto, K., “Plastic Collapse Evaluation on the Notched Stainless Steel Piping Subjected to Combined Tension and Bending by Photo-Plastic Coating,” Key Engineering Materials 270–273: 2001–2005 (2004).

Izawa, S., Matsubara, M., Hirao, N., et al., “Combined Tension–Bend System for Large Deformation Analysis,” Experimental Techniques 31: 41–45 (2007).

Izawa, S., Matsubara, M., Hirao, N., et al., “Plastic Collapse Behavior of a SUS316 Single-Edge Notched Member Subjected to Combined Tension and Bending Using Photo-Plastic Coating Technique,” JSEM 4(1): 55–60 (2004).

Green, A.P., “The Plastic Yielding of Notched Bars due to Bending,” Quarterly Journal of Mechanics and Applied Mathematics 6: 223–229 (1953).

Rice, J.R. “The Line Spring Model for Surface Flows,” Proceedings of Surface Flaw Symposium, ASME Winter Annual Meeting, pp. 71–184 (1972).

Hundy, B.B., “Plane Plasticity,” Metallurgia 49: 109–118 (1954).

Klecker, R.W., Bush, S.H., Hou, S.H., Strosnider, J., Wichman, K.R.., Report of the U.S. Nuclear Regulatory Commission Piping Review Committee Evaluation of Potential for Pipe Breaks 4: A-33 (1984).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Suzuki, R., Matsubara, M., Sakamoto, K. et al. Observation and Evaluation of Plastic Collapse for Double-Notch Pipe. Exp Tech 40, 253–260 (2016). https://doi.org/10.1007/s40799-016-0030-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-016-0030-z