Abstract

In this study, the Powder River Basin (PRB) coal fast pyrolysis was conducted at 700 °C in the atmosphere of syngas produced by CH4–CO2 reforming in two different patterns, including the double reactors pattern (the first reactor is for syngas production and the second is for coal pyrolysis) and double layers pattern (catalyst was at upper layer and coal was at lower layer). Besides, pure gases atmosphere including N2, H2, CO, H2–CO were also tested to investigate the mechanism of the coal pyrolysis under different atmospheres. The pyrolysis products including gas, liquid and char were characterized, the result showed that, compared with the inert atmosphere, the tar yield is improved with the reducing atmospheres, as well as the tar quality. The hydrogen partial pressure is the key point for that improvement. In the atmosphere of H2, the tar yield was increased by 31.3% and the contained BTX (benzene, toluene and xylene) and naphthalene were increased by 27.1% and 133.4%. The double reactors pattern also performed outstandingly, with 25.4% increment of tar yield and 25.0% and 79.4% for the BTX and naphthalene. The double layers pattern is not effective enough due to the low temperature (700 °C) in which the Ni-based catalyst was not fully activated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

As the biggest source of CO2 emission, fossil fuel combustion supplies more than 85% of energy for industrial activities, particularly coal is on a path to supply 28% of global energy by 2030, while as part of a 57% increase in CO2 emissions (Haszeldine 2009). Considering the challenge of energy conservation and carbon dioxide emission reduction, propelling the development of coal-to-chemicals technology while reducing the carbon emission during this process is one of the most important pathways to deal with the environmental issues.

To utilize the aromatics in coal, pyrolysis is an idea pathway with relatively sample process, in the meantime, comprehensive utilization of pyrolysis products including gas, tar and char is realized. Large number of researches (Finn et al. 1980; Fynes et al. 1980; Zhang et al. 2018) focusing on the coal pyrolysis has summarized the favorable conditions for the extracting the tar and valuable light aromatics containing in tar, e.g. rapid heating rate, low-rank coal, hydrogenation phenomenon etc. Based on the situation abovementioned, in this research, an innovative integrated system named integrated coal pyrolysis system coupled with CO2 capture and conversion technology is proposed, in which all the CO2 generated in the process is fully converted and utilized (Wang et al. 2019).

Traditional coal pyrolysis produces coal tar containing mostly polycyclic aromatic hydrocarbons, after catalytic hydrogenation, the heteroatoms were removed and the small aromatic hydrocarbons including methylbenzene, naphthalene etc. were generated via decomposition of the polycyclic aromatic hydrocarbons. It is generally agreed that the presence of hydrogen during the coal pyrolysis increases overall coal conversion, especially for Western low-rank coals such as Wyoming subbituminous coal and North Dakota lignite, because of the substantial property and structural difference between them, which, in general makes the low-rank coals more susceptible to reaction with H2, CO, or H2S (Schobert 1984). In the meantime, the H radicals help the decomposition of the large aromatic rings in the tar, favoring the formation of the small aromatic rings e.g. toluene, xylene and naphthalene that improve the value of the tar (Jüntgen 1984). In some researches, catalysts were loaded on the coal for higher tar yield and the light compounds (Feng et al. 2015; Ma et al. 2012), however, those catalysts remaining in the char increase the difficulty for the following up utilization. It is also favorable for the following utilization of the coal char produced by hydropyrolysis, due to the lower contents of S and N in it (Ariunaa et al. 2007; Xu and Kumagai 2002).

Most of the researches were focusing on the coal hydropyrolysis, but the influence of CO on the thermal behavior of coal has not been extensively studied. Liao et al. (1998a, b, c) had done systematic research on coal hydropyrolysis using coke-oven gas and syngas as pyrolysis atmospheres. Braekman-Danheux et al. (1995) also regarded the coke oven gas as an good option for the coal pyrolysis since the coal conversion and the oil and gas yields in coke oven gas are always lower than in pure hydrogen, but higher than in nitrogen. The research team of Hu (Liu et al. 2010; Wang et al. 2013) developed the integrated process of CO2 reforming methane and coal pyrolysis (CRMP) technology, using the reforming reaction to provide free radical for the coal devolatilization, the tar yield with the CRMP was 1.6 and 1.8 times as that in coal pyrolysis under H2 and N2. It was also found that the presence of CO also promoted the desulfurization of product gas compared with the pure H2 atmosphere (Ariunaa et al. 2007). CO exhibits advantageous tar yield without H2. Gao et al. (2013, 2014b) studied the lignite pyrolysis in CO and N2, and found the CO resulted in the breakdown of the aromatic rings, side chains, ether bond and aliphatic chain, thus increasing the amount of radical and the stabilizing the fragment during the pyrolysis, indicated by the promoted yield of small gaseous molecules.

So far, the effect of CO and the CO in syngas on coal pyrolysis is still unclear, especially on the gaseous and char products. Therefore, in this study, the possibility of using syngas from the dry methane reforming (DMR) as a reactive gas for coal pyrolysis to improve the economics of the hydropyrolysis process was exolored. Additionally, the coal pyrolysis in pure gas atmospheres (N2, H2, CO, H2–CO) were conducted at 600–800 °C to investigate the mechanism of the coal pyrolysis under different atmospheres.

2 Experimental

2.1 Coal sample and catalyst preparation

The coal samples used in this study is the Wyodak sub-bituminous coal from the Powder River Basin, Wyoming, USA, with the particle size below 74 μm. Before experiments, the coal was dried in a vacuum oven at 105 °C for 12 h. The properties of the selected coal were given in Table 1.

For the DMR, MgAl2O4 was used as the support to load the catalyst Ni. Catalyst preparation process started with calcining as received MgAl2O4 at 600 °C for 3 h, followed by impregnation with nickel nitrate solution. The resulting impregnated sample in thick paste was dried at 105 °C for 24 h and then decomposed as well as calcined at 950 °C for 5 h. The concentration of nickel in the catalyst was 10 wt%.

Coal pyrolysis was conducted under different temperatures (600, 650, 700, 750 and 800 °C) and atmospheres (N2, H2, CO, H2–CO and syngas produced by the DMR), using a fixed bed reactor (Quartz reactor, 12 mm in internal diameter, 550 mm in length) as showed in Fig. 1. After 2.0 g dry coal was loaded in the reactor, the gas started to purge through the coal bed with the flow rate of 30 SCCM, sweeping out the air in the system for 20 min. In the meantime, the furnace was heated to the target temperature. The pyrolysis started when the reactor was quickly placed into the preheated furnace and then hold for 20 min, the thermocouple was placed in the reactor and indicated the average heating rate of the coal is 175 °C /min. The reactor was then taken out of the furnace and naturally cooled down to the room temperature. For the gas analysis, the off gas during the pyrolysis was collected with a gas bag, and analyzed with a micro GC (Inficon Micro GC 3000); to collect the generated liquid, a three-stage gas washing bottles with CHCl3 as solvent were placed at the outlet of the reactor, as the volatile flowing through the bottles, the tar and water would be absorbed and condensed. The solution collected was subsequently filtered, vaporized to remove the most of the CHCl3 and formed condensed tar solution, then the solution was diluted to 15 mL for the GC–MS (Agilent, 7890B) analysis and tar yield measurement. 5 mL tar solution was transported to the aluminum plate, and placed into the vacuum oven to vaporize the CHCl3 at 50 °C for 0.5 h, the tar rested in the plated was weighed for the tar production calculation.

Schematic diagram of fixed bed coal pyrolysis system. 1—H2 cylinder; 2—CO cylinder; 3—N2 cylinder; 4—mass flow controller, Parker 201, 0–100 mL/min; 5—mass flow controller box; 6—HPLC pump; 7—vertical tubular furnace, Carbolite VST 12/300; 8—quartz reactor, inner diameter of 1.2 cm, length of 55 cm; 9—thermocouple and temperature recorder; 10—condenser/coal tar trap system with CHCl3; 11—moisture trap with dried CaSO4 inside; 12—gas chromatograph, Inficon micro GC 3000; 13—computer

The PRB coal fast pyrolysis in syngas was conducted at 700 °C in three different patterns: (1) coal pyrolysis in the mixture of the H2 and CO; (2) coal pyrolysis in prefabricate syngas produced by CH4–CO2 reforming facilitated by another reactor, i.e. the first reactor is for syngas production at 900 °C, and second reactor is for coal pyrolysis, termed as RP-SP; (3) the DMR and coal pyrolysis were integrated in one reactor, i.e. catalyst was at upper layer and coal was at lower layer, termed as RP-2L.

2.2 Characterization

2.2.1 TGA (thermogravimetric analysis)

TGA (TA Instruments, SDT Q600 apparatus) were used to evaluate the PRB coal pyrolysis characteristic in atmospheres. 30 mg coal was loaded onto a ceramic capped alumina sample holder and heated to 105 °C in specific gas stream (100% N2, 50% H2–50% N2 and 50% CO–50% N2). After 20 min of isothermal equilibration at 105 °C to remove the contained moisture, the sample was subsequently heated at 40 °C/min to 1000 °C.

2.2.2 Elemental analyzer

The C, H, N, S and O content in the coal, char and tar were analyzed with the elemental analyzer (Elementar, Vario MACRO CUBE), 50 mg sample was combusted in the combustion tube at 1250 °C with 400 mL/min O2, the O content was differenced by C, H, N, S content.

2.2.3 GC–MS

The composition of coal tar was analyzed by GC–MS, equipped with HP-5 capillary column to separate the components in the tar which were then detected with mass spectra for possible molecular formula. The operation conditions were as follows: flowrate of helium (carrier gas), 25 mL/min; solvent delay, 2.5 min; interface temperature, 250 °C; initial temperature, 40 °C, heating rate, 4 °C. The components with intensity higher than 100000 in the GC–MS total ion chromatogram was analyzed, and categorized into 6 groups, i.e. aromatics (benzene, toluene and xylenes), phenols (phenol, cresol, xylenols, benzenediols and naphthols), naphthalenes (naphthalene, methylnaphthalenes and dimethylnaphthalenes), aliphatics (olefins and alkanes), PAHs (indenes, anthracenes, phenanthrenes, fluorenes and pyrenes) and Heteroatoms (furans, ketones, esters, alcohols and acids). The amount of those components in the coal tar were 180–200.

2.2.4 Raman spectra

Raman spectra reported here were acquired by using a Renishaw InVia Raman spectrometer with excitation laser at 532 nm to scan the char-KBr pellets. The obtained spectra in the range between 800 and 1800 cm−1 were curve-fitted with the with PEAKFIT 4.0 software using 10 Gaussian bands, such as in Fig. 2. The detail of the method was reported in the research of Li (Bai et al. 2017; Li 2013; Li et al. 2006a).

2.2.5 XRD (X-ray diffraction)

Crystalline structures of the semicoke were analyzed by XRD system manufactured by Rigaku with Cu Kα radiation in the 2θ ranging from 10° to 90°. The working voltage and current of the X-ray tube were fixed at 40 kV and 40 mA, respectively. All X-ray diffraction patterns were analyzed using Jade 7.5 of Material Data, Inc. (MDI), and peak profiles of individual reflections were determined by a nonlinear least-squares fit of the Cu Kα corrected data.

PeakFit V4.0 software was applied to fit the diffractograms using Gaussian functions in the 2θ regions of 16°–34° and 37.5°–48°. The broad hump in the region of 16°–34° (2θ) was fitted to two Gaussian peaks around 20° and 26°, representing γ-band and π-band (d002), respectively. The peak positions, intensities, widths, and area were determined. The average carbon crystallite lattice parameters: aromaticity (\({f}_{\text{a}}\)), inter-layer spacing (d002), crystallite height (Lc), crystallite diameter (La) and the average number of aromatic layers per carbon crystallite (Nave) were determined using the empirical Braggs and Scherrer equations (Eqs. (1–5)) (Johnson et al. 1986; Machado et al. 2013; Okolo et al. 2015; Zhang et al. 2013).

where \({\lambda }\) is the wavelength of the incident X-ray (in this case 1.54056 Å for Cu Ka radiation); \({\theta }_{002,10}\) is the peak position of (002) or (10) band (°); \({\beta }_{002,10}\) is the full width at half maximum (FWHM) of the corresponding peak or band (°); \({K}_{\text{c,a}}\) is a constant depending on X-ray refection plane, 0.89 for the (002) band and 1.84 for the (10) band.

3 Results and discussions

3.1 Effects of atmospheres and temperatures on products and elements distribution of coal pyrolysis

To study the pyrolysis characteristic of PRB coal, the coal was pyrolyzed in N2, H2 and CO atmospheres on TGA, the result is shown in Fig. 3. The coal was continuous losing weight during the heating up to 1000 °C with the fasted devitalization at 400–500 °C in all three atmospheres. It is indicated that the H2 and CO atmosphere could contribute to the decomposition of coal compared with the N2, as the weight losses in the reducing gases were greater than that in inert gas when the temperature was higher than 400 °C. During 500–650 °C, coal pyrolysis in the CO atmosphere showed a higher devolatilization degree compared with H2 atmospheres, the higher content of reactive oxygenated bonds (e.g. carboxyl or ether linkages) in low-rank coals could be the reason for the high reactivity in the presence of CO (Schobert 1984). When the temperature went higher than 650 °C, the devolatilization effect of CO weakened while that of H2 was still attacking the bonds in the coal char and leading to a continuous weight loss of char. Till 1000 °C, the weight loss of coal in H2 was 51.1%, higher than 44.6% in CO and 42.9% in N2. This was attributed to the H radical generation was favored at higher temperature, so does the decomposition of CO to carbon and CO2. Therefore, the H2 could accelerate the decomposition of char while the CO generated carbon on the surface of char and leaded to a much slower rate of coal pyrolysis (Gao et al. 2014a). This phenomenon was obvious at the temperature between 800 and 1000 °C. Therefore, the two reducing atmosphere are advantageous to the devitalization of coal, which is consistent with the result from other research article (Braekman-Danheux et al. 1995). CO performed best at 450–660 °C; while for H2, it has consistent effect when the temperature was higher than 450 °C; at 630–700 °C, H2 and CO have nearly the same decomposition effect on the coal.

The coal pyrolysis in N2, H2 and CO was also performed on a fixed bed reactor at various temperatures from 600 to 800 °C, the products distribution including char, gas and liquid were investigated and calculated as follows:

where \(m_{\text{gas, out}}\) is the mass of gases collected by the gas bags during the pyrolysis; \(m_{\text{gas, in}}\) is the mass of gases introduced into the reactor, which was deducted In the Eq. (6), means the \(m_{\text{gas}}\) is the mass of gas produced by the coal pyrolysis itself. Thereby, the mass of liquid (\(m_{\text{liquid}}\)) and the mass of char (\(m_{\text{char}}\)) as shown in Eq. (7) are also form coal, excluding the consumption of the gas atmospheres. \({Y}_{{{\text{gas}}/{\text{char}}/{\text{liquid}}}}\) is the yields of three kinds of products based on the coal shown in Eq. (8).

Figure 4 shows the product yields of coal pyrolyzed under various temperatures (600–800 °C) and atmospheres (N2, H2 and CO). The horizontal dash lines in the Fig. 4 represents the highest yield of gas and liquid, and the lowest yield of the char, as the standard for comparison. The Yield of gas and char were monotonously increased and decreased respectively, with the increments of pyrolysis temperatures, indicating the greater decomposition degree of the cross-linked structure in the char, forming more small molecules i.e. the gases. The lowest char yield is 55.3% at 800 °C under CO; for H2 and N2, that values are 55.8% and 56.3%. Liquid yield was increased at lower temperature and then decreased at higher temperature in all three atmospheres, the highest values appeared at different temperatures, e.g. 22.4% in N2 at 750 °C, 24.2% in H2 at 650 °C and 25.25% in CO at 700 °C. The phenomenon presented above is accorded with the basic coal pyrolysis characteristic. When the temperature rises above 400 °C, the depolymerization effect and heteroatom removal reactions are enhanced, performing as the rising liquid yield; when the temperature is higher than 700 °C, the macromolecule in the volatile decomposed into the smaller, leading to the promoted gas yield and the reduced liquid yield.

The distribution of the C, H and O elements in gas, liquid and char produced under different conditions is shown in Fig. 5. For C distribution, with the increasing temperature, the C in gas increased and that in char decreased; while in the liquid, the variation trends for inert and reduction atmospheres were different. In N2 atmosphere, the C in the liquid reduced when the temperature from 600 to 800 °C, while that in H2 and CO firstly increased and then decreased, the maximum value appeared at 650 and 700 °C, respectively.

The distribution of H in char, gas and liquid showed monotonous decreasing, increasing and decreasing trends respectively, with the rising pyrolysis temperature in all three atmospheres. As show in Fig. 5, the H in char was barely affected by the atmospheres, the value decreased from ~ 30% at 600 °C to ~ 10% at 800 °C. Distinction was found in the H distribution of the gas, the value of H in the gas produced in H2 atmosphere is lower than that in N2 and CO, which was due to the deduction of the introduced H2. The H2 in pyrolysis gas was greatly consumed, leading to the increase of H in liquid as show in the Fig. 5. The maximum value of H distribution in the liquid was 62.9% at 600 °C in H2 atmosphere, compared with 56.2% and 54.4% in N2 and CO at 600 °C respectively. The H2 atmosphere also obviously reduced the O content in the char, transferred them mainly to the liquid. The CO atmosphere also helped the O in the gas transferring to the liquid and the char, especially at 650–700 °C.

Therefore, summarizing the products and elements distribution in the coal pyrolysis at 600–800 °C in N2, H2 and CO, it was found that H2 atmosphere could helped the C, H, an O moving to the liquid. While, the CO is capable of transferring the C to the liquid. They are both the favorable conditions for the improvement of tar yield and quality, thus the best temperature for this goal is 650–700 °C. Considering the highest liquid yield in CO at 700 °C, thus 700 °C was selected as the temperature for further coal pyrolysis investigation.

3.2 Effects of coal pyrolysis conditions on gaseous products distribution

The effect of temperature and atmosphere on gaseous products (H2, CO, CH4 and CO2) distribution was presented in Fig. 6. It is assumed that all the introduced gas was not reacting with the coal, however, the fact is part of them were consumed by the coal pyrolysis, thus the decreased amount H2 and CO could be attributed to the reaction between the reducing gas and coal. The moles of H2 production was negative at 600 and 650 °C, which means the generation of H2 by coal pyrolysis could not meet the requirement of the consumption of H2 at these temperatures, until 700 °C or higher. The same situation also happened for CO, at 600 °C the production of CO was nearly zero. Thus, compared with the values in N2, the consumption values of the H2 and CO are nearly 0.0020 and 0.0012 mol/g, basically consistent under various temperatures.

The production of CH4 by coal pyrolysis in H2 was increased. The H2 atmosphere provided larger amount of H for the coal pyrolysis, which was utilized to break down the cross-link structure of coal, stabilize the decomposed large radical, and attack the heteroatom. The amount of CH4 was increased under the H2 atmosphere since the CH3 was stabilized with H then forming the CH4 rather than reacted in the secondary polymerization between volatiles (Jüntgen 1984). H2 was also capable of attacking the O in the coal and forming water (Ibarra et al. 1988), thus the CO and CO2 production under H2 atmosphere was lower than that in N2.

The moles of H2, CO and CH4 under the conditions in this experiment were obviously increased with higher temperature, while the CO2 reached the maximum yield at 700 °C, then kept nearly unchanged. The source of CO2 is the decomposition of carboxyl which starts to decompose at ~ 400 °C, thus for the PRB coal, the complete composition temperature of the carboxyl was 700 °C. The CO2 production was increased in the CO atmosphere, by which the CO may capture the oxygen from hydroxyl and subsequently generate the CO2.

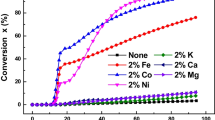

3.3 Effects of coal pyrolysis conditions on liquid products distribution

The tar yield at 700 °C in different atmospheres was shown in Fig. 7. It was 7.83% under N2 atmosphere at 700 °C, and efficiently improved in reducing atmospheres. 10.29% of the tar yield was achieved under H2 atmospheres, which was higher than 9.11% in CO and 10.01% in H2-CO. Thus, the value was increased by 31.3%, 16.4% and 27.8% in three reducing atmospheres. The performance of H2 is better than the CO, and there is no synergy between H2 and CO to improve the tar yield. The syngas from the DMR was less effective compared with the pure H2-CO, the tar yield in PR-SP was 9.82% and that in RP-2L was 8.49%. The result indicated that the higher H2 partial pressure was the key parameter for the increment for the tar yield, the CO was also favorable. The syngas form the DRM contained parts of the unreacted CO2 and CH4, lowered the partial pressure of effective gases, thus the performance was limited. The temperature for coal pyrolysis is 700 °C, still lower than the suitable reaction temperature for CH4-CO2 reforming (900 °C), thus the syngas partial pressure was not enough for the coal pyrolysis as pure syngas introduction. When the temperature was increased to 800 °C, tar yield was improved to 9.2%.

The compounds analysis of the obtained tars was shown in Table 2, and the valuable chemicals including the BTX, PCX and naphthalene was specifically listed in Table 3. The hydropyrolysis of coal clearly improved the content of aromatics, naphthalenes and PAHs. Especially for the BTX and naphthalene, their contents were increased by 27.1% and 133.4% in the H2 atmosphere compared to the inert. In the meantime, the contents of phenols, aliphatics and heteroatoms were decreased. Also, the H2 containing gases had the similar effect on the tar components distribution, however in different extents. As the H radicals generated, it attacks the aliphatic bond between aromatic systems, benefited the production of the large aromatic rings, e.g. the PAHs. H radical would continue to decompose the condensed rings, forming smaller aromatic ring, by which the contents of the aromatics and the naphthalenes were promoted. The increase of the aromatics was attributed to the reaction between the H radicals and the phenols, producing the water which was also generated by the hydrogenation of heteroatoms.

Similarly, CO reduced the heteroatoms content in the tar, indicating it could react with the oxygen in ether and hydroxyl. In the meantime, the CO increased the content of phenols in the tar. The improvement of phenols in co-pyrolysis of coal and CO was also confirmed by other researchers (Braekman-Danheux et al. 1995; Liao et al. 1998b), through the inhibiting effect of CO on the decomposition of phenols: post-cracking of PCX leading to carbon monoxide and BTX is partly inhibited by the carbon monoxide present in the gas, thus the content of aromatics was lower than that in N2. The polarity of CO can facilitate the cracking of the aromatic ring.

Aromatics, phenols and naphthalene are light aromatic chemicals that are most value-added for the coal pyrolysis industry. The H2 atmosphere obviously increased the content of aromatics and naphthalenes in the tar to 12.44% and 8.68% respectively, compared with 11.80% and 6.62% in N2. While for the phenols, the syngas improved the percentages of aromatics and naphthalene to 12.82% and 9.8% respectively, compared with 11.80% and 6.62% in inert atmosphere. In addition, the phenol, aliphatic and heterocycles were decreased with the presence of syngas, which as well indicated the improvement of the tar quality and ease to produce chemicals in the downstream industry.

3.4 Effects of coal pyrolysis conditions on char

Figure 8 showed the Raman spectrum of pyrolysis semicoke produced in different atmosphere. Calculation results of deconvolution of a Raman spectrum for the char produced under different atmosphere are shown in Table 4. The ID/IG ratio indicates the concentrations of aromatic rings having six or more fused benzene (Li et al. 2006a). The value of ID/IG in N2 atmosphere is 1.42, that in H2, H2-CO and RP-SP are increased to 1.49, 1.59 and 1.53, respectively. While, the value of ID/IG is decreased in CO and RP-2L. The value of ID/IGR represents the relative proportion of the large ring system (≥ 6 rings) and the small ring system (3–5 rings). It revealed that, under the effect of hydrogen radicals, the methylene or ether oxygen bond between the macromolecular structure and the small ring in the coal macromolecular structure breaks, and the small ring is detached from the char and enriched in tar, resulting in the decrease of its content in the semicoke structure, so the relative proportion of the large ring system (≥ 6 rings) and the small ring system (3–5 rings) in the semicoke increases. The results of tar analysis abovementioned also confirmed it. In H2 atmosphere, the content of polycyclic aromatic hydrocarbons above tricyclic in pyrolysis tar was significantly higher than that in N2, which evidenced the separation of small ring system from coal structure. Compared with IS% (representing the concentration of Caromatic–Calkyl; aromatic (aliphatic) ethers; C–C on hydroaromatic rings) in inert atmosphere, the value in reducing atmosphere decreased from 0.11 to 0.07 or 0.09, which indicated that reducing atmosphere was conducive to the reduction of cross-linking degree in coal char and assisted in the removal of substituents in large aromatic structure (Li et al. 2006b). Compared with pure gases, the effect of reforming syngas is more obvious, because there is a small amount of water vapor and carbon dioxide in the reforming syngas, so the gasification reaction with coal char occurs. Compared with hydrogenation, gasification is more effective in reducing the disorder structure.

In the aspect of total Raman peak area, the peak area of semicoke in H2 and H2–CO is lower than that in N2, which shows the destruction of heteroatoms including oxygen-containing functional groups and sulfur-containing and nitrogen-containing heterocycles in reducing atmosphere. The reduction effect of RP-SP and RP-2L is more obvious, which proves that the disordered structure was taken out prior to the carbon skeleton in the gasification reaction. In CO atmosphere, the Raman peak area of semicoke is higher than that in N2, indicating that CO increases the oxygen content in semicoke. From the distribution of O in the semicoke at 700 °C, it is slightly higher than that in N2 atmosphere. Therefore, it is speculated that the lone pair electrons contained in CO may be involved in the reaction with the aromatic ring in the coal char, and the oxygen atoms stay in the coal char.

Theoretically, based on the XRD result, the areas under the γ- and Π -peaks are believed to be equal to the number of aliphatic carbon atoms (Cal) and aromatic carbon atoms (Car), respectively. Therefore, the \(A_{002}\)/\(A_{\upgamma }\) and the \(f_{{\text{a}}}\) could be used to determine the aromaticity of the carbon. As shown in the Table 5, the chars produced under the H2, CO and syngas have larger values of these two indexes, indicating much more crystalline carbon like graphite and higher ordered degree. Also, the char produced in H2 atmosphere is with highest \(A_{002}\)/\(A_{\upgamma }\) and the \(f_{{\text{a}}}\) values, which means the H2 attacks and removes the aliphatic groups, generating more liquid products, leaving the char with higher graphitized form. Based on the values of CO and syngas, it could be concluded that both H2 and CO are capable for improving the graphitization degree, and the H2 obviously plays a critical role. Due to the effect of both H2 and CO, crystallite diameter (La) and the inter-layer spacing (d002) decreased compared with that under inert atmosphere. This could be explained with the positive effect of these two gases on the polycondensation during the coal pyrolysis, they enable removing aliphatic side chains which are not strongly bonded to the coal matrix, detaching from the coal matrix and forming volatiles. Larger polycondensation degree means the growth of the graphite layer structure and the forming condensed and highly ordered graphite structure.

4 Conclusion

In this paper, the distribution and properties of pyrolysis products of the Wyodak sub-bituminous coal in different atmospheres are analyzed, the influence of atmospheres on the pyrolysis behavior and products of coal is explored, and the interaction mechanism between coal and reducing gas is revealed. The conclusions are as follows:

The coal pyrolysis on TGA and in fixed bed reactor showed that reduction atmosphere is helpful to the depolymerization of macromolecules in coal, resulted in higher liquid product yield of coal pyrolysis. H2 atmosphere has the most obvious effect on coal depolymerization, which increases the content of C, H and O in liquid products and the yield of gaseous hydrocarbon in pyrolysis gas. The effect of CO is relatively weak, which increases the proportion of C in liquid products and H in gas, and increases the content of CO2 in pyrolysis gas.

The analysis of coal pyrolysis tar shows that the yield of tar can be increased in reducing atmosphere, and the partial pressure of H2 is the main factor. At 700 °C, the yield of tar increased by 31.3% under pure H2, the contained BTX and naphthalene increased by 27.1% and 133.4% respectively. In the DMR-pyrolysis coupled experiment, the prefabricated syngas shows better performance, the tar yield is increased by 25.4%, the BTX and naphthalene contents are increased by 25.0% and 79.4%, respectively.

According to structure characterization of semicoke obtained in different atmospheres, it is found that H2 has obvious effect on the removal of small aromatic ring system (3–5 rings), side chain of aliphatic hydrocarbon and secondary cracking of volatile; while the lone pair electrons contained in CO induce the cracking of benzene ring in coal structure, and increase the fracture degree of side chain, ether bond and aliphatic chain, increase the yield of tar and lead to the formation of oxygen functional groups in coal char increase.

References

Ariunaa A et al (2007) Coal pyrolysis under synthesis gas, hydrogen and nitrogen. J Fuel Chem Technol 35:1–4. https://doi.org/10.1016/S1872-5813(07)60007-3

Bai Y, Zhu S, Luo K, Gao M, Yan L, Li F (2017) Coal char gasification in H2O/CO2: release of alkali and alkaline earth metallic species and their effects on reactivity. Appl Therm Eng 112:156–163. https://doi.org/10.1016/j.applthermaleng.2016.10.044

Braekman-Danheux C, Cyprès R, Fontana A, van Hoegaerden M (1995) Coal hydromethanolysis with coke-oven gas: 2. Influence of the coke-oven gas components on pyrolysis yields. Fuel 74:17–19. https://doi.org/10.1016/0016-2361(94)P4324-U

Feng J, Xue X, Li X, Li W, Guo X, Liu K (2015) Products analysis of Shendong long-flame coal hydropyrolysis with iron-based catalysts. Fuel Process Technol 130:96–100. https://doi.org/10.1016/j.fuproc.2014.09.035

Finn MJ, Fynes G, Ladner WR, Newman JOH (1980) Light aromatics from the hydropyrolysis of coal. Fuel 59:397–404

Fynes G, Ladner WR, Newman JOH (1980) The hydropyrolysis of coal to BTX. Prog Energy Combust Sci 6:223–232

Gao S, Zhou J, Wang Z, Zhao J, Fang Y, Huang J (2013) Effect of CO on fast pyrolysis behaviors of lignite. J Fuel Chem Technol 41:550–556

Gao S, Wang J, Wang Z, Zhao J, Fang Y (2014a) Effect of CO on the CH4 evolution during fast pyrolysis of lignite in reductive atmospheres. J Anal Appl Pyrolysis 106:104–111. https://doi.org/10.1016/j.jaap.2014.01.006

Gao S, Wang J, Zhao J, Wang Z, Fang Y, Huang J (2014b) CH4 release character from pressurized fast pyrolysis of lignite in CO atmosphere. J Fuel Chem Technol 42:641–649

Haszeldine RS (2009) Carbon capture and storage: How green can black be? Science 325:1647–1652

Ibarra J, Moliner R, Miranda J, Cyprès R (1988) Pyrolysis under H2 and He of Utrillas coal. Fuel 67:464–468. https://doi.org/10.1016/0016-2361(88)90340-7

Johnson C, Patrick J, Mark T (1986) Characterization of coal chars by raman spectroscopy X-ray diffraction and reflectance measurements. Fuel 65:1284–1290. https://doi.org/10.1016/0016-2361(86)90243-7

Jüntgen H (1984) Review of the kinetics of pyrolysis and hydropyrolysis in relation to the chemical constitution of coal. Fuel 63:731–737. https://doi.org/10.1016/0016-2361(84)90058-9

Li CZ (2013) Importance of volatile–char interactions during the pyrolysis and gasification of low-rank fuels—a review. Fuel 112:609–623. https://doi.org/10.1016/j.fuel.2013.01.031

Li X, Hayashi J-I, Li C-Z (2006a) FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal. Fuel 85:1700–1707. https://doi.org/10.1016/j.fuel.2006.03.008

Li X, Hayashi J-i, Li C-Z (2006b) Volatilisation and catalytic effects of alkali and alkaline earth metallic species during the pyrolysis and gasification of Victorian brown coal. part VII Raman spectroscopic study on the changes in char structure during the catalytic gasification in air. Fuel 85:1509–1517. https://doi.org/10.1016/j.fuel.2006.01.011

Liao H, Li B, Zhang B (1998a) Co-pyrolysis of coal with hydrogen-rich gases. 1 Coal pyrolysis under coke-oven gas and synthesis gas. Fuel 77:847–851. https://doi.org/10.1016/S0016-2361(97)00257-3

Liao H, Li B, Zhang B, Liu Z (1998b) Copyrolysis of coal with coke oven gas IV influence of CH4 and CO on pyrolysis yields. J Fuel Chem Technol 26:13–17

Liao H, Sun C, Li B (1998c) Copyrolysis of coal with coke oven gas III. Analyses of tar. J Fuel Chem Technol 26:7–12

Liu J, Hu H, Jin L, Wang P, Zhu S (2010) Integrated coal pyrolysis with CO2 reforming of methane over Ni/MgO catalyst for improving tar yield. Fuel Process Technol 91:419–423. https://doi.org/10.1016/j.fuproc.2009.05.003

Ma Z, Ma X, Luo J, Xu L, Yang F (2012) Catalytic hydropyrolysis of five chinese coals. Energy Fuels 26:511–517. https://doi.org/10.1021/ef201290v

Machado AdS, Mexias AS, Vilela ACF, Osorio E (2013) Study of coal, char and coke fines structures and their proportions in the off-gas blast furnace samples by X-ray diffraction. Fuel 114:224–228. https://doi.org/10.1016/j.fuel.2012.07.064

Okolo GN, Neomagus HWJP, Everson RC, Roberts MJ, Bunt JR, Sakurovs R, Mathews JP (2015) Chemical–structural properties of South African bituminous coals: Insights from wide angle XRD–carbon fraction analysis, ATR–FTIR, solid state 13C NMR, and HRTEM techniques. Fuel 158:779–792. https://doi.org/10.1016/j.fuel.2015.06.027

Schobert HH (1984) The chemistry of low-rank coals vol 264. In: ACS symposium series, vol 264. American Chemical Society. https://doi.org/10.1021/bk-1984-0264

Wang P, Jin L, Liu J, Zhu S, Hu H (2013) Analysis of coal tar derived from pyrolysis at different atmospheres. Fuel 104:14–21. https://doi.org/10.1016/j.fuel.2010.06.041

Wang X et al (2019) High-performance nano-structured Ni based catalysts for high-temperature CO2-CH4 reforming—Greenhouse gases to syngas. Catal Today 339:344–351. https://doi.org/10.1016/j.cattod.2019.06.040

Xu WC, Kumagai M (2002) Nitrogen evolution during rapid hydropyrolysis of coal. Fuel 81:2325–2334. https://doi.org/10.1016/S0016-2361(02)00169-2

Zhang Y, Kang X, Tan J, Frost RL (2013) Influence of calcination and acidification on structural characterization of anyang anthracites. Energy Fuels 27:7191–7197. https://doi.org/10.1021/ef401658p

Zhang L, Qi S, Takeda N, Kudo S, Hayashi J, Norinaga K (2018) Characteristics of gas evolution profiles during coal pyrolysis and its relation with the variation of functional groups International Journal of. J Coal Sci Technol 5:452–463. https://doi.org/10.1007/s40789-017-0175-0

Acknowledgements

The author would like to appreciate the funding supports of the State of Wyoming and China Scholarship Council. Without their supports, the international collaboration on clean energy technology development would have been impossible.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, X., Wei, B., Huang, X. et al. Enhanced near-zero-CO2-emission chemicals-oriented oil production from coal with inherent CO2 recycling: Part I—PRB coal fast pyrolysis coupled with CO2/CH4 reforming. Int J Coal Sci Technol 7, 433–443 (2020). https://doi.org/10.1007/s40789-020-00359-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40789-020-00359-4