Abstract

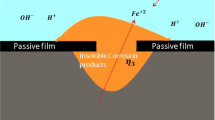

Aluminum finds applications in various industries that require enhanced corrosion resistance. However, this metal remains susceptible to various forms of deterioration, with the most common being localized corrosion. This type of corrosion is characterized by local degradation of the oxide film in sufficiently aggressive environments. In the present work, a two-dimensional (2D) model incorporating a distribution of secondary current with deformed geometry was employed to investigate the behavior of aluminum pitting corrosion in a 1 M sodium chloride solution. Specifically, the study focused on the kinetics of pitting corrosion, the geometric deformation occurring during the pit growth process, and the influence of electrolyte conductivity on the propagation of pitting corrosion. Conclusions drawn from numerical simulations reveal that ohmic drop determines the kinetics of corrosion propagation along the metal wall of the pit and, thereby serves as the principal factor controlling the progression of the pit.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Kania H (2023) Corrosion and anticorrosion of alloys/metals: the important global issue. Coatings 13:216. https://doi.org/10.3390/coatings13020216

G Koch, J Varney, N Thompson, O Moghissi, M Gould, J Payer (2016) International measures of prevention, application, and economics of corrosion technologies study, NACE Int. Impact. 1–216

Harzheim S, Hofmann M, Wallmersperger T (2022) Comparison of two mesh-moving techniques for finite element simulations of galvanic corrosion. Acta Mech 233:4427–4439. https://doi.org/10.1007/s00707-022-03326-z

Ilzsg R (2017) World directory of continuous galvanizing lines. NY, USA, New York

Duddu R, Kota N, Qidwai SM (2016) An extended finite element method based approach for modeling crevice and pitting corrosion. J Appl Mech. https://doi.org/10.1115/1.4033379

Li X, Zhao Y, Qi W, Wang J, Xie J, Wang H, Chang L, Liu B, Zeng G, Gao Q, Sun H, Zhang T, Wang F (2019) Modeling of pitting corrosion damage based on electrochemical and statistical methods. J Electrochem Soc 166:C539–C549. https://doi.org/10.1149/2.0401915jes

Jafarzadeh S, Chen Z, Bobaru F (2019) Computational modeling of pitting corrosion. Corros Rev 37:419–439. https://doi.org/10.1515/corrrev-2019-0049

Sun W, Wang L, Wu T, Liu G (2014) An arbitrary Lagrangian-Eulerian model for modelling the time-dependent evolution of crevice corrosion. Corros Sci 78:233–243. https://doi.org/10.1016/j.corsci.2013.10.003

Brewick PT, Kota N, Lewis AC, DeGiorgi VG, Geltmacher AB, Qidwai SM (2017) Microstructure-sensitive modeling of pitting corrosion: effect of the crystallographic orientation. Corros Sci 129:54–69. https://doi.org/10.1016/j.corsci.2017.09.009

Liu C, Kelly RG (2019) A review of the application of finite element method (FEM) to localized corrosion modeling. Corrosion 75:1285–1299. https://doi.org/10.5006/3282

Kota N, Qidwai SM, Lewis AC, DeGiorgi VG (2013) Microstructure-based numerical modeling of pitting corrosion in 316 stainless steel. ECS Trans 50:155–164. https://doi.org/10.1149/05031.0155ecst

Mouloudi M, Radouani R, Essahli M, Chafi M, Chhiba M (2021) Study of corrosion pit propagation in aluminum by numerical simulation using the finite element method. Int J Electrochem Sci 16:21119. https://doi.org/10.20964/2021.11.24

Ansari TQ, Xiao Z, Hu S, Li Y, Luo J-L, Shi S-Q (2018) Phase-field model of pitting corrosion kinetics in metallic materials. Npj Comput Mater 4:38. https://doi.org/10.1038/s41524-018-0089-4

Mouloudi M, Essahli M, Chhiba M, Chafi M (2022) Numerical study of aluminum pitting corrosion using a two-dimensional multi-species transport model. Int J Electrochem Sci 17:221286. https://doi.org/10.20964/2022.12.77

Peng J, Ji G, Shi Z, Wang X (2021) Numerical simulation based on a ZrO 2 -coated stainless-steel corrosion experiment. ACS Omega 6:14504–14517. https://doi.org/10.1021/acsomega.1c01461

Hamer WJ, DeWane HJ (1970) Electrolytic conductance and the conductances of the hydrohalogen acids in water. Natl Bur Stand 8:33

Shojaei E, Mirjalili M, Moayed MH (2019) The influence of the crevice induced IR drop on polarization measurement of localized corrosion behavior of 316 L stainless steel. Corros Sci 156:96–105. https://doi.org/10.1016/j.corsci.2019.04.030

Gaudet GT, Mo WT, Hatton TA, Tester JW, Tilly J, Isaacs HS, Newman RC (1986) Mass transfer and electrochemical kinetic interactions in localized pitting corrosion. AIChE J 32:949–958. https://doi.org/10.1002/aic.690320605

Tricoit S (2012) Modeling and numerical simulation of iron pitting corrosion propagation in chloride media. University of Burgundy, UFR Sciences et Techniques The laboratory Interdisciplinaire Carnot de Bourgogne, Andra, France

Bundy K (2008) Biomaterials and the chemical environment of the body. Joint replacement technology. Elsevier, Amsterdam, pp 56–80. https://doi.org/10.1533/9781845694807.1.56

A. G46–94 (2013) Standard guide for examination and evaluation of pitting corrosion. ASTM International, West Conshohocken, pp 1–8. https://doi.org/10.1520/G0046-21

NL Okita (2009) The correlation between conductivity and corrosion potential of solutions in simulation of an oil field environment

Xu Y, Wang M, Pickering HW (1993) On electric field induced breakdown of passive films and the mechanism of pitting corrosion. J Electrochem Soc 140:3448–3457. https://doi.org/10.1149/1.2221108

Obeyesekere NU (2017) Pitting corrosion. Trends in oil and gas corrosion research and technologies. Elsevier, Amsterdam, pp 215–248. https://doi.org/10.1016/B978-0-08-101105-8.00009-7

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

MM: Formal analysis, Investigation, Methodology, Software, Writing—original draft; AEG: writing—review and editing, Validation; MC: Supervision, Validation; MC: Supervision, Validation; ME: Supervision, Project, Resources, administration. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mouloudi, M., El Guerraf, A., Chhiba, M. et al. Numerical Model of Aluminum Pitting Corrosion in a 1M Sodium Chloride Solution Using Secondary Current Distribution. J Bio Tribo Corros 10, 48 (2024). https://doi.org/10.1007/s40735-024-00851-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-024-00851-3