Abstract

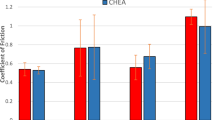

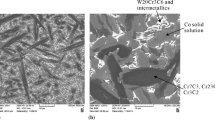

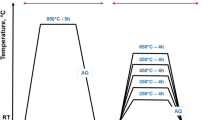

A low-carbon steel sheet welding joint, which was coated and uncoated, was investigated in the present study using the TIG welding procedure in order to measure corrosion behavior in both types of joints. It was determined that the sheet welded joints, both coated and uncoated, were all subjected to the same test conditions, which included immersion in a corrosive environment containing a neutral solution of a concentration of 3.5% sodium chloride and a concentration of pH 7 at room temperature. The extent to which the surface characteristics of the welding joints were affected by these conditions was evaluated for periods ranging between 1, 2, 3, 4, and 5 months. The surface properties of the surface were significantly changed after completing each period, including topography, roughness, and corrosion products after completing each period. During the experiment, the results revealed that after 5 months of being coated with a NaCl solution with a concentration of 3.5%, the roughness values decreased in coated specimens, as well as the corrosion products were reduced.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Baboian R (2005) Corrosion tests and standards: application and interpretation, 2nd edn. ASTM, Philadelphia

Pistofidis N, Vourlias G, Konidaris S, Pavlidou E, Stergiou A, Stergioudis G (2006) Microstructure of zinc hot-dip galvanized coatings used for corrosion protection. Mater Lett 60(6):786–789. https://doi.org/10.1016/j.matlet.2005.10.013

Abdulsada SA, Al-Mosawi AI (2022) Corrosion behaviour and surface topography for steel plates used in automotive industry exposed to salty corrosive thermo-accelerated medium. J Silic Based Compos Mater 74(6):218–223

Abdulsada SA, Al-Mosawi AI (2023) Analysis of corrosion rate, inhibition efficiency, and economic cost of XD3 reinforced concrete related to inhibitor and plasticiser types. Eng Res Express 5(3):035032. https://doi.org/10.1088/2631-8695/acee46

Al-Kafaji JK, Al-Mosawi AI (2014) Adding hydrazine to pigments to prevent corrosion of ferrous alloys, University of Kerbala Journal, Special Issue for 2nd scientific conference, science College, University of Kerbala, Iraq, 26–27 February 2014. https://doi.org/10.6084/m9.figshare.19180982

Vera R, Valverde B, Olave E, Sánchez R, Díaz- Gómez A, Muñoz L, Rojas P (2023) Atmospheric corrosion and impact toughness of steels: case study in steels with and without galvanizing, exposed for 3 years in Rapa Nui Island. Heliyon 9(7):e17811. https://doi.org/10.1016/j.heliyon.2023.e17811

Mutlu IH, Emre MC, Kaya AO (2023) A comparison of the corrosion resistance of galvanized low steel with solgel method coated ZrO2, ZrO2+polymer coating. Kuwait J Sci 50(4):524–538. https://doi.org/10.1016/j.kjs.2023.08.004

Peng BC, Wang JH, Su XP, Li Z, Yin FC (2008) Effects of zinc bath temperature on the coatings of hot-dip galvanizing. Surf Coat Technol 202:1785–1788. https://doi.org/10.1016/j.surfcoat.2007.07.044

Dallin GW (2015) Galvanizing, technical report, Galvinfo Center—a program of the international zinc association. https://www.galvinfo.com/wp-content/uploads/sites/8/2017/12/Galvanizing-2015.pdf

Tisza M (2020) Development of lightweight steels for automotive applications. In: Sharma A, Duriagina Z, Kumar S (eds) Engineering steels and high entropy-alloys. IntechOpen, London

Schubert E, Klassen M, Zemer I, Walz C, Sepold G (2001) Lightweight structures produced by laser beam joining for future applications in automobile and aerospace industry. J Mater Process Technol 115(1):2–8. https://doi.org/10.1016/S0924-0136(01)00756-7

Yamane K, Furuhama S (1998) A study on the effect of the total weight of fuel and fuel tank on the driving performances of cars. Int J Hydrogen Energy 23(9):825–831. https://doi.org/10.1016/S0360-3199(97)00125-0

Jambor A, Beyer M (1997) New cars-new materials. Mater Des 18(4–6):203–209. https://doi.org/10.1016/S0261-3069(97)00049-6

Cheon SS, Lee DG, Jeong KS (1997) Composite side door impact beams for passenger cars. Compos Struct 38(1–4):229–239. https://doi.org/10.1016/S0263-8223(97)00058-5

Li Y, Lin Z, Jiang A, Chen G (2003) Use of high strength steel sheet for lightweight and crashworthy car body. Mater Des 24:177–182. https://doi.org/10.1016/S0261-3069(03)00021-9

Schulz U, Trubiroha P, Schernau U, Baumgart H (2000) The effects of acid rain on the appearance of automotive paint systems studied outdoors and in a new artificial weathering test. Prog Org Coat 40(1–4):151–165. https://doi.org/10.1016/S0300-9440(00)00138-7

Akafuah NK, Poozesh S, Salaimeh A, Patrick G, Lawler K, Saito K (2016) Evolution of the automotive body coating process—a review. Coatings 6(2):24. https://doi.org/10.3390/coatings6020024

Abdulsada SA, Al-Mosawi AI, Török TI (2017) Testing the inhibition potential of fenugreek seed powders on steel rebar samples immersed in aqueous NaCl solution. In: Proceedings of multiscience—XXXI. microCAD international multidisciplinary scientific conference, University of Miskolc, Hungary, 20–21 April 2017. https://doi.org/10.26649/musci.2017.026

Alcántara J, de la Fuente D, Chico B, Simancas J, Díaz I, Morcillo M (2017) Marine atmospheric corrosion of carbon steel: a review. Materials 10(4):406. https://doi.org/10.3390/ma10040406

ISO 25178-2, Geometrical product specifications (GPS)—surface texture: areal—part 2: terms, definitions and surface texture parameters. International Organization for Standardization-ISO, 2012. ISO 21920-3:2021

Geometrical product specifications (GPS)—surface texture: profile, part 3: specification operators. International Organization for Standardization-ISO (2021)

Acknowledgements

We are grateful to Mr. Árpád Kovács at the scanning electron microscopy lab, Miskolci Egyetem, for his valuable assistance with the SEM–EDAX measurements.

Funding

The authors certify that they received no funding for this work.

Author information

Authors and Affiliations

Contributions

Shaymaa Abbas Abdulsada and Ali I. Al-Mosawi wrote the main manuscript text and prepared all the figures and tables. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical Approval

The authors certify the ethics approval and consent to participate.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdulsada, S.A., Al-Mosawi, A.I. Surface Characteristics and Corrosion Tendency of TIG-Welded Low Carbon Steel Sheet Affected Cold Galvanizing and Processed by Immersion in Sodium Chloride Solution. J Bio Tribo Corros 10, 34 (2024). https://doi.org/10.1007/s40735-024-00838-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-024-00838-0