Abstract

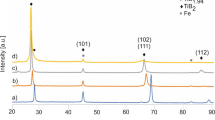

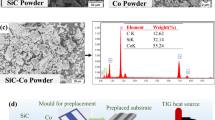

In this study, the abrasion wear behavior of borided AISI 1045 steel under dry and wet conditions was evaluated. The powder-pack boriding process (PPBP) was carried out at 1223 K with 8 and 10 h of exposure using EKabor-II boride powder for dry and wet abrasion tests. A biphasic layer composed of FeB and Fe2B was obtained over the surface of the AISI 1045 steel with a thickness of ~ 265 and ~ 304 μm for 8 and 10 h, respectively. Afterwards, when the PPBP was accomplished, the diffusion annealing process (DAP) was carried out at 1273 K with 8 and 10 h of exposure time in a SiC medium, obtaining a monophasic layer of Fe2B of ~ 212 μm and ~ 250 μm with 8 and 10 h, respectively. Dry and wet abrasion wear tests on PPBP, PPBP + DAP, and reference material of AISI 1018 steel were performed, considering the guidelines of the ASTM G105-16 and ASTM G65-16 standard procedures. Finally, 8 h the PPBP improves the wear rate around ~ 24 and ~ 12 times compared to the reference material, and 8 h the PPBP + DAP under dry conditions, respectively. However, 10 h the PPBP improved the wear rate around ~ 23 and ~ 7 times compared to the reference material, and 10 h the PPBP + DAP under wet conditions, respectively. The main failure mechanisms over the worn tracks in both experimental conditions were smearing and spalling, as evidenced by SEM–EDS techniques.

Similar content being viewed by others

References

Holmberg K, Matthews A (2009) Coatings tribology: properties, mechanisms, techniques and applications in surface engineering, Elsevier, United Kingdom. https://books.google.com/books?id=SuTrD-AHpyUC&pgis=1.

S. Affatato, D. Brando, 1 (2013) Introduction to wear phenomena of orthopaedic implants, In: SBTW. of OI, Affatato AJ (ed), Woodhead Publ. Ser. Biomater., Woodhead Publishing, pp 3–26. https://doi.org/10.1533/9780857096128.1.3

Eyre TS (1976) Wear characteristics of metals. Tribol Int 203–213

García-Léon RA, Martínez-Trinidad J, Campos-Silva I (2021) Historical review on the boriding process using bibliometric analysis. Trans Indian Inst Met. https://doi.org/10.1007/s12666-020-02174-6

Kulka M (2019) Current trends in boriding: techniques. Switzerland. https://doi.org/10.1007/978-3-030-06782-3

García-Léon RA, Martínez-Trinidad J, Campos-Silva I, Wong-Angel W (2020) Mechanical characterization of the AISI 316L alloy exposed to boriding process. DYNA 87:34–41

Campos-Silva IE, Rodríguez-Castro GA (2015) 18 - Boriding to improve the mechanical properties and corrosion resistance of steels. In: Thermochem Surf Eng Steels. Woodhead Publishing, Oxford, pp 651–702. https://doi.org/10.1533/9780857096524.5.651.

Campos-Silva I, Ortiz-Domínguez M, López-Perrusquia N, Escobar-Galindo R, Gómez-Vargas OA, Hernández-Sánchez E (2009) Determination of boron diffusion coefficients in borided tool steels, defect diffus. Forum 283–286:681–686. https://doi.org/10.4028/283-286.681

Von Matuschka G, Boronising, Carl Hanser Verlag (1980)

Keddam M, Chentouf SM (2005) A diffusion model for describing the bilayer growth (FeB/Fe2B) during the iron powder-pack boriding. Appl Surf Sci 252:393–399. https://doi.org/10.1016/j.apsusc.2005.01.016

Şahin S (2009) Effects of boronizing process on the surface roughness and dimensions of AISI 1020, AISI 1040 and AISI 2714. J Mater Process Technol 209:1736–1741. https://doi.org/10.1016/j.jmatprotec.2008.04.040

Campos-Silva I, Flores-Jiménez M, Bravo-Bárcenas D, Balmori-Ramírez H, Andraca-Adame J, Martínez-Trinidad J, Meda-Campaña JA (2017) Evolution of boride layers during a diffusion annealing process. Surf Coatings Technol 309:155–163. https://doi.org/10.1016/j.surfcoat.2016.11.054

Wirojanupatump S, Shipway PH (2000) Abrasion of mild steel in wet and dry conditions with the rubber and steel wheel abrasion apparatus. Wear 239:91–101. https://doi.org/10.1016/S0043-1648(00)00310-0

Tressia G, Penagos JJ, Sinatora A (2017) Effect of abrasive particle size on slurry abrasion resistance of austenitic and martensitic steels. Wear 376–377:63–69. https://doi.org/10.1016/j.wear.2017.01.073

Tozetti KD, Albertin E, Scandian C (2017) Abrasive size and load effects on the wear of a 19.9% chromium and 2.9% carbon cast iron. Wear. https://doi.org/10.1016/j.wear.2017.02.008

Hosseini P, Radziszewski P (2011) Combined study of wear and abrasive fragmentation using Steel Wheel Abrasion Test. Wear 271:689–696. https://doi.org/10.1016/j.wear.2010.12.044

Meric C, Sahin S, Backir B, Koksal NS (2006) Investigation of the boronizing effect on the abrasive wear behavior in cast irons. Mater Des 27:751–757. https://doi.org/10.1016/j.matdes.2005.01.018

Béjar MA, Moreno E (2006) Abrasive wear resistance of boronized carbon and low-alloy steels. J Mater Process Technol 173:352–358. https://doi.org/10.1016/j.jmatprotec.2005.12.006

Santos A, Remolina A, Marulanda J (2016) Influence of alumina and titanium dioxide coatings on abrasive wear resistance of AISI 1045 steel. J Phys Conf Ser. https://doi.org/10.1088/1742-6596/687/1/012015

Altintaş A, Sarigün Y, Çavdar U (2016) Effect of Ekabor 2 powder on the mechanical properties of pure iron powder metal compacts. Rev Metal 52:e073. https://doi.org/10.3989/revmetalm.073

Calik A (2013) Effect of Powder Particle Size on the Mechanical Properties of Boronized EN H320 LA Steel Sheets. Isij Int 53:160–164. https://doi.org/10.2355/isijinternational.53.160

ISO-14577–4 (2016) Metallic materials - Instrumented indentation test for hardness and materials parameters. In: ISO, pp 1–10

ASTM G65–16e1 (2016) Standard test method for measuring abrasion using the dry sand/rubber wheel apparatus, West Conshohocken, PA. https://www.astm.org/.

ASTM G105–16 (2016) Standard Test Method for Conducting Wet Sand/Rubber Wheel Abrasion Tests, West Conshohocken, PA. https://www.astm.org/

Krelling AP, Teixeira F, da Costa CE, dos S. de Almeida EA, Zappelino B, Milan JCG (2019) Microabrasive wear behavior of borided steel abraded by SiO2 particles. J Mater Res Technol 8:766–776. https://doi.org/10.1016/j.jmrt.2018.06.004

Martini C, Palombarini G, Carbucicchio M (2004) Mechanism of thermochemical growth of iron borides on iron. J Mater Sci 39:933–937. https://doi.org/10.1023/B:JMSC.0000012924.74578.87

García-León RA, Martinez-Trinidad J, Zepeda-Bautista R, Campos-Silva I, Guevara-Morales A, Martínez-Londoño J, Barbosa-Saldaña J (2021) Dry sliding wear test on borided AISI 316L stainless steel under ball-on-flat configuration: A statistical analysis. Tribol. Int. 157:106885. https://doi.org/10.1016/j.triboint.2021.106885

Martini C, Palombarini G, Poli G, Prandstraller D (2004) Sliding and abrasive wear behaviour of boride coatings. Wear 256:608–613. https://doi.org/10.1016/j.wear.2003.10.003

Hunger HJ, Trute G (1994) Boronizing to produce wear-resistant surface layers. Heat Treat Met 21:31–39

García-León RA, Martínez-Trinidad J, Campos-Silva I (2021) Historical review on the boriding process using bibliometric analysis. Trans Indian Inst Met 74:541–557. https://doi.org/10.1007/s12666-020-02174-6

Rodríguez-Castro G, Campos-Silva I, Martínez-Trinidad J, Figueroa-López U, Arzate-Vázquez I, Hernández-Sánchez E, Hernández-Sánchez J (2012) Mechanical behavior of AISI 1045 steels subjected to powder-pack boriding. Kov Mater 50:357–364. https://doi.org/10.4149/km-2012-5-357

Kul M, Danacı I, Karaca B (2020) Effect of boronizing composition on hardness of boronized AISI 1045 steel. Mater Lett 279:128510. https://doi.org/10.1016/j.matlet.2020.128510

Reséndiz-Calderon CD, Rodríguez-Castro GA, Meneses-Amador A, Campos-Silva IE, Andraca-Adame J, Palomar-Pardavé ME, Gallardo-Hernández EA (2017) Micro-abrasion wear resistance of borided 316L stainless steel and AISI 1018 steel. J Mater Eng Perform 26:5599–5609. https://doi.org/10.1007/s11665-017-3004-0

ASTM, A240–17 (2017) Standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications. ASTM Int I. https://doi.org/10.1520/A0240

Zecchi E, Carbucicchio M, Palombarini G, Sambogna G (1983) Phase composition and structure of boride layers grown on laboratory-cast low-chromium alloys. J Mater Sci 18:3355–3362

Badini C, Gianoglio C, Pradelli G (1987) The effect of carbon, chromium and nickel on the hardness of borided layers. Surf Coatings Technol 30:157–170. https://doi.org/10.1016/0257-8972(87)90140-X

Liu Y, Liskiewicz TW, Beake BD (2019) Dynamic changes of mechanical properties induced by friction in the Archard wear model. Wear 428–429:366–375. https://doi.org/10.1016/j.wear.2019.04.004

Leyland A, Matthews A (2000) On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 246:1–11. https://doi.org/10.1016/S0043-1648(00)00488-9

Fox-Rabinovich GS, Veldhuis SC, Scvortsov VN, Shuster LS, Dosbaeva GK, Migranov MS (2004) Elastic and plastic work of indentation as a characteristic of wear behavior for cutting tools with nitride PVD coatings. Thin Solid Films 469–470:505–512. https://doi.org/10.1016/j.tsf.2004.07.038

Taktak S (2007) Some mechanical properties of borided AISI H13 and 304 steels. Mater Des 28:1836–1843. https://doi.org/10.1016/j.matdes.2006.04.017

Wirojanupatump S, Shipway PH (1999) A direct comparison of wet and dry abrasion behaviour of mild steel. Wear 233–235:655–665

Holmberg K, Matthews A (2009) Coatings tribology, second edition: properties, mechanisms, techniques and applications in surface engineering. Elsevier, United Kingdom. https://doi.org/10.1016/S0301-679X(98)00013-9.

Campos-Silva I, Flores-Jiménez M, Rodríguez-Castro G, Hernández-Sánchez E, Martínez-Trinidad J, Tadeo-Rosas R (2013) Improved fracture toughness of boride coating developed with a diffusion annealing process. Surf Coatings Technol 237:429–439. https://doi.org/10.1016/j.surfcoat.2013.05.050

Hernández-Ramírez EJ, Guevara-Morales A, Figueroa-López U, Campos-Silva I (2020) Wear resistance of diffusion annealed borided AISI 1018 steel. Mater Lett 277:128297. https://doi.org/10.1016/j.matlet.2020.128297

Hawk JA, Wilson RD, Danks DR, Kiser MT (2002) Abrasive wear failures. Fail Anal Prev. https://doi.org/10.31399/asm.hb.v11.a0003560

Garcia-Bustos E, Figueroa-Guadarrama MA, Rodríguez-Castro GA, Gómez-Vargas OA, Gallardo-Hernández EA, Campos-Silva I (2013) The wear resistance of boride layers measured by the four-ball test. Surf Coatings Technol 215:241–246. https://doi.org/10.1016/j.surfcoat.2012.08.090

Atar E, Kayali ES, Cimenoglu H (2008) Characteristics and wear performance of borided Ti6Al4V alloy. Surf Coatings Technol 202:4583–4590. https://doi.org/10.1016/j.surfcoat.2008.03.011

Hutchings IM (1992) Tribology: friction and wear of engineering materials. Edward Arn, London

Bhushan B (1999) Principles and application of tribology. Wiley-Inte, New York

Eyre TS (1976) Wear characteristics of metals. Tribol Int 9:203–212. https://doi.org/10.1016/0301-679X(76)90077-3

Hutchings IM (1992) Tribology friction and wear of engineering materials, dward Arno, United Kingdom

Acknowledgements

This work was supported by the research Grant 20211111 of the Instituto Politécnico Nacional of México.

Author information

Authors and Affiliations

Contributions

JAM and CA. GB: investigation and formal analysis. JMT: methodology, supervision, project administration, conceptualization, formal analysis, and funding acquisition. ICS: methodology, conceptualization, supervision, and other contributions. WD. WÁ and JG. BS: conceptualization, methodology, and other contributions. RA. GL: formal analysis, conceptualization, original draft, and writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

There are no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ambrosio-Martínez, J., Gómez-Bustamante, C., Martínez-Trinidad, J. et al. Dry and Wet Abrasion Wear Resistance on Borided AISI 1045 Steel. J Bio Tribo Corros 7, 154 (2021). https://doi.org/10.1007/s40735-021-00589-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00589-2