Abstract

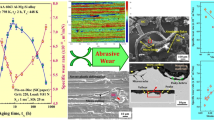

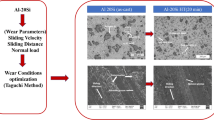

The present research deals with the fabrication of Al–Si–Mg-Sr alloy cast using a permanent mould. At different ageing temperatures and time, the cast alloys were heat-treated for the improvement of tribological properties. The alloys were solutionized for 12 h at 525 °C and aged at different ageing temperatures and time. The wear processes parameter used for the present investigation were ageing temperature, ageing time, and applied load. Pin-on-Disc tribometer was used for performing the wear test. The tribological characteristics of the alloy cast were investigated using response surface methodology. The investigation found that the alloying of strontium refined the microstructure of Al–Si–Mg. It was noted from the findings obtained that there was a substantial change in the value of the specific wear rate and coefficient of friction as the wear process factors were varied. Moreover, the worn-out surface analysis on the heat-treated specimens was studied using a scanning electron microscope

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- RSM:

-

Response surface methodology

- DoE:

-

Design of Experiments

- xi:

-

Ith experimental parameters/factor

- Y:

-

Response

- b0 :

-

Mean values of the responses i.e., constant of regression equation

- bi :

-

Linear coefficient of factor xi in regression equation

- bii :

-

Quadratic coefficients of factor xi in the regression equation

- bij :

-

Interaction constant coefficients between the factors xi ad xj in the regression equation

- FCCD:

-

Face-centered central composite design

- p-value:

-

Probability value defined as the probability that the observed results could occur when the null hypothesis is true

- R2 :

-

The coefficient of determination

- adj. R2 :

-

Adjusted R2 defined as the percentage of response variable variation that is explained by its relationship with one or more predictor variables, adjusted for the number of predictors in the model

- OHNS:

-

Oil hardened non – shrinkage steel

- cof / COF:

-

Coefficient of friction

References

Pacz A, Alloy. U.S. Patent No. 1387900; 1921. - Google Scholar.” ,

Guan RG, Tie D (2017) “A review on grain refinement of aluminum alloys: progresses, challenges and prospects. Acta Metall Sin English Lett 30(5):409–432

Mazahery A, Shabani MO (2014) Modification mechanism and microstructural characteristics of eutectic Si in casting Al-Si alloys: a review on experimental and numerical studies. JOM 66(5):726–738

Campbell J (2009) The modification of Al-Si casting alloys: important practical theoretical aspects. Int J Met 3(1):65–67

Samuel AM, Samuel FH, Doty HW, Valtierra S (2017) New method of eutectic silicon modification in cast Al-Si alloys. Int J Met 11(3):475–493

Liu, T., Morales, S., Karkkainen, M., Brewer, L. N., Nastac, L., Arvikar, V., and Levin, I., 2018, “The Combined Effects of Sr Additions and Heat Treatment on the Microstructure and Mechanical Properties of High Pressure Die Cast A383 Alloy,” Minerals, Metals and Materials Series, pp. 253–257.

Öztürk İ, Hapçı Ağaoğlu G, Erzi E, Dispinar D, Orhan G (2018) Effects of strontium addition on the microstructure and corrosion behavior of A356 aluminum alloy. J Alloys Compd 763:384–391

Uludağ M, Çetin R, Dispinar D, Tiryakioğlu M (2018) The effects of degassing, grain refinement & Sr-addition on melt quality-hot tear sensitivity relationships in cast A380 aluminum alloy. Eng Fail Anal 90:90–102

V, vijeesh, “The Effect of Strontium Modification on T6 Heat Treatment Parameters, Microstructure and Hardness of Aluminum Silicon- A356 Alloy.”

Derin S (2017) Effect of strontium addition on microstructure and mechanical properties of AlSi7Mg0.3 alloy removing inclusions from aluminum alloys view project developing the cooling performance in low pressure die casting of A356 alloy view project. Springer 11(4):688–695

Lin YC, Luo SC, Huang J, Yin LX, Jiang XY (2018) Effects of solution treatment on microstructures and micro-hardness of a Sr-modified Al-Si-Mg alloy. Mater Sci Eng A 725:530–540

Dong Z, Hu Z, Yan H, Xie H, Li X (2019) Solidification Behavior and Microstructure of Al-7Si Alloys with Individual and Combined Additions of Sr and Yb. Mater. Sci. Eng, Adv. https://doi.org/10.1155/2019/9750526

Zhang W, Ma S, Wei Z, Bai P (2019) The Relationship between residual amount of Sr and morphology of eutectic Si phase in A356 alloy. Materials (Basel) 12(19):3222

Xugang D, Jie Z, Yaojun J, Bin L, Zhenzhen L, Wenhao W, Huan B (2011) Influence of Sr on microstructure and mechanical properties of ZL114 Cast Alloy. China Foundry 8(4):401–406

Liao H, Sun G (2003) Mutual poisoning effect between Sr and B in Al-Si casting alloys. Scr Mater 48(8):1035–1039

Samuel AM, Doty HW, Gallardo SV, Samuel FH (2016) The effect of Bi-Sr and Ca-Sr Interactions on the microstructure and tensile properties of Al-Si-based alloys. Materials (Basel) 9(3):126

El-Hadad S, Samuel AM, Samuel FH, Doty HW, Valtierra S (2006) Role of Bi and Ca Additions in Controlling the Microstructure of Sr-Modified 319 Alloys. Trans Tech Publications Ltd, Materials Science Forum, pp 1257–1264

Zamani M, Seifeddine S (2016) Determination of optimum Sr level for eutectic Si modification in Al-Si cast alloys using thermal analysis and tensile properties. Int J Met 10(4):457–465

Cho YH, Lee HC, Oh KH, Dahle AK (2008) Effect of strontium and phosphorus on eutectic Al-Si nucleation and formation of β-Al5FeSi in hypoeutectic Al-Si foundry alloys. Metall Mater Trans A Phys Metall Mater Sci 39(10):2435–2448

Zarif, M., McKay, B., and Schumacher, P., 2011, “Study of Heterogeneous Nucleation of Eutectic Si in High-Purity Al-Si Alloys with Sr Addition,” Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, pp. 1684–1691.

Fortini A, Lattanzi L, Merlin M, Garagnani GL (2018) Comprehensive evaluation of modification level assessment in Sr-modified aluminium alloys. Int J Met 12(4):697–711

Miresmaeili, S., Campbell, J., A, S. S. M. T., and 2005, undefined, “Precipitation of Sr-Rich Intermetallic Particles and Their Influence on Pore Formation in Sr-Modified A356 Alloy,” Springer.

Miresmaeili SM, Shabestari SG, Boutorabi SMA (2003) The Effect of SR-modification treatment on porosity formation of reduced pressure 319 Al alloy castings. Can Metall Q 42(2):245–252

Priyanka Muddamsetty LV, Radhika N (2016) Effect of heat treatment on the wear behaviour of functionally graded LM13/B4C composite. Tribol Ind 38(1):108–114

Radhika N, Raghu R (2018) Prediction of mechanical properties and modeling on sliding wear behavior of LM25/TiC composite using response surface methodology. Part Sci Technol 36(1):104–111

Sharma S (2014) Parametric study of abrasive wear of Co-Crc based flame sprayed coatings by response surface methodology. Tribol Int 75:39–50

Nithesh R, Radhika N, Shiam Sunder S (2017) Mechanical properties and adhesive scuffing wear behavior of stir Cast Cu-Sn-Ni/Si3N4 composites. J Tribol, Doi 10(1115/1):4036185

Koksal S, Ficici F, Kayikci R, Savas O (2012) Experimental optimization of dry sliding wear behavior of in situ AlB2/Al composite based on taguchi’s method. Mater Des 42:124–130

International, E. R.-A., Handbook, M., Edition., T., and 1990, U., 2018, “Introduction to Aluminum and Aluminum Alloys,” Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, pp. 3–14.

“ASTM G99–17, Standard Test Method for Wear Testing”

Radhika N, Raghu R (2015) Dry Sliding Wear Behaviour of Aluminium Al-Si12Cu/TiB2 Metal Matrix Composite Using Response Surface Methodology. Lett, Tribol. https://doi.org/10.1007/s11249-015-0516-3

Shankar KV, Sellamuthu R (2016) An investigation on the effect of nickel content on the wear behaviour and mechanical properties of spinodal bronze alloy cast in metal mould. Int J Mater Eng Innov 7(2):89–103

Dwivedi DK (2002) Influence of modifier and grain refiner on solidification behaviour and mechanical properties of cast Al-Si base alloy. J Inst Eng 83:46–49

Mondolfo, L., 2013, Aluminum Alloys: Structure and Properties.

Dwivedi DK, Sharma A, Rajan TV (2005) Influence of silicon morphology and mechanical properties of piston alloys. Mater Manuf Process 20(5):777–791

Barrirero J, Engstler M, Ghafoor N, De Jonge N, Odén M, Mücklich F (2014) Comparison of segregations formed in unmodified and sr-modified al-si alloys studied by atom probe tomography and transmission electron microscopy. J Alloys Compd 611(611):410–421

Srirangam P, Chattopadhyay S, Bhattacharya A, Nag S, Kaduk J, Shankar S, Banerjee R, Shibata T (2014) Probing the local atomic structure of Sr-modified Al-Si alloys. Acta Mater 65:185–193

Czerwinski, F., 2012, Heat Treatment - Conventional and Novel Applications.

Archard, J., Of, W. H.-P. of the R. S., and 1956, U (1956) The wear of metals under unlubricated conditions. Proc R Soc London Ser A Math Phys Sci 236(1206):397–410

Balachandran M, Devanathan S, Muraleekrishnan R, Bhagawan SS (2012) Optimizing properties of nanoclay-nitrile rubber (nbr) composites using face centred central composite design. Mater Des 35:854–862

Kumar, T. S., Nampoothiri, J., Raghu, R., Shalini, S., and Subramanian, R., 2019, “Development of Wear Mechanism Map for Al–4Mg Alloy/MgAl2O4 In Situ Composites,” Trans. Indian Inst. Met.

Thandalam SK, Ramanathan S, Sundarrajan S (2015) Synthesis, microstructural and mechanical properties of ex situ zircon particles (ZrSiO4) reinforced metal matrix composites (MMCs): a review. J Mater Res Technol 4(3):333–347

Yang CY, Lee SL, Lee CK, Lin JC (2006) Effects of Sr and Sb modifiers on the sliding wear behavior of A357 alloy under varying pressure and speed conditions. Wear 261(11–12):1348–1358

Song WQ, Krauklis P, Mouritz AP, Bandyopadhyay S (1995) The effect of thermal ageing on the abrasive wear behaviour of age-hardening 2014 Al/SiC and 6061 Al/SiC composites. Wear 185(1–2):125–130

Yusoff Z, Jamaludin SB (2011) Tribology and development of wear theory. Int J Curr Res Rev 3(2):13–26

Liu G, Li G, Cai A, Chen Z (2011) The influence of strontium addition on wear properties of Al-20wt% Si alloys under dry reciprocating sliding condition. Mater Des 32(1):121–126

Basavakumar KG, Mukunda PG, Chakrabortyb M (2008) Influence of grain refinement and modification on dry sliding wear behavior of Al-12Si and Al-12Si-3Cu cast alloys. Int J Mater Res 99(8):900–906

Rajeev VR, Dwivedi DK, Jain SC (2010) Dry reciprocating wear of Al-Si-SiCp composites: a statistical analysis. Tribol Int 43(8):1532–1541

Syahrial AZ, Pancasakti A (2017) Effect of Aging on characterization of Sr-modified stir cast A356/Al2O3 composite. Key Engin Mater 753:33–38

Siddhartha Prabhakar N, Radhika N, Raghu R (2014) Analysis of tribological behavior of aluminium/B4C composite under dry sliding motion. Procedia Engineering 97:994–1003

Akhil MG, Preenu S, Hari S, Ravi M (2019) Effect of heat treatment on the mechanical properties of squeeze-Cast Al–5Si–3Cu alloy for automotive applications. Trans Indian Inst Met 72(5):1129–1132

Fatahalla N, Hafiz M, Abdulkhalek M (1999) Effect of microstructure on the mechanical properties and fracture of commercial hypoeutectic Al-Si alloy modified with Na, Sb and Sr. J Mater Sci 34(14):3555–3564

Shin SS, Kim ES, Yeom GY, Lee JC (2012) Modification effect of Sr on the microstructures and mechanical properties of Al-10.5Si-2.0Cu recycled alloy for die casting. Mater Sci Eng A 532:151–157

Sui Y, Wang Q, Wang G, Liu T (2015) Effects of Sr content on the microstructure and mechanical properties of Cast Al-12Si-4Cu-2Ni-0.8Mg alloys. J Alloys Compd 622:572–579

Arunagiri KS, Radhika N (2016) Studies on adhesive wear characteristics of heat treated aluminium LM25/AlB2 composites. Tribology in Industry 38(3):277–285

Parida J, Pattnaik SC, Mishra SC, Behera A (2020) Effect of heat treatment on wear behaviour of al-7 wt%Si-X wt% mg alloys. Paper presented at the Materials Today: Proceedings 33:4976–4980. https://doi.org/10.1016/j.matpr.2020.02.828

Nidhin Raj A, Sellamuthu R (2016) Determination of hardness, mechanical and wear properties of cast al-mg-si alloy with varying ni addition. ARPN Journal of Engineering and Applied Sciences 11(9):5946–5952

Funding

No funds, grants, or other support was received.

Author information

Authors and Affiliations

Contributions

Conceptualization was done by KVS; Methodology was done by BSPK and VSK; Formal analysis and investigation were carried out by KVS and MB; Writing—original draft preparation was done by KVS, MB and HAR; Writing—review and editing was carried out by KVS and MB; Funding acquisition was done by BSP, KSR, VSK and NSH; Resources was done by BSP, SRK, VSK and NSH; Supervision was done by KVS and MB.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Consent to participate

All the authors in this investigation voluntarily agree to participate in this research study.

Consent for Publication

All the authors in this investigation gives the permission to the publisher to publish the Work if accepted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shankar, K.V., Balachandran, M., Pillai, B.S. et al. Influence of T6 Heat Treatment Analysis on the Tribological Behaviour of Cast Al-12.2Si-0.3 Mg-0.2Sr Alloy Using Response Surface Methodology. J Bio Tribo Corros 7, 96 (2021). https://doi.org/10.1007/s40735-021-00531-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00531-6