Abstract

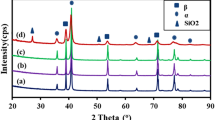

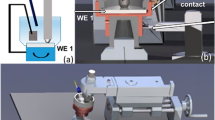

Saliva is a potentially aggressive environment due to the presence of acids, chloride, and pH variation, thus the dental implant system can be subjected to corrosion in this medium. Due to masticatory loads during chewing, the joint of implant rehabilitation is subjected to relative micromovements among components leading to a microgap formation and wear. Furthermore, dissimilar alloys in contact at joint interface of dental implant system can potentially drive to electrochemical galvanic couple occurrence. Torque relaxation can be enhanced by corrosion caused by the infiltration of saliva in the microgap. This study aimed to evaluate the influence of saliva and its pH variations on corrosion and tribocorrosion of alloys employed in dental implant system. NiCr, cp-Ti, and Ti6Al4V alloys were evaluated through electrochemical tests in artificial saliva at pH 3.0 and 6.0. The possible occurrence of the galvanic couple for a 3:1 area ratio and their effects were also verified by electrochemical measurements. SEM and confocal microscopy were used for the analysis of worn surfaces. Corrosion polarization tests did not indicate the potential occurrence of galvanic corrosion in saliva. NiCr was more susceptible to localized corrosion and more resistant to tribocorrosion in acidified and neutral artificial saliva than titanium-based alloys. Coupled alloys did not present differences in tribocorrosion performance when compared to each isolate alloy in neutral saliva, pH 6.0. For pH 3.0, Ti6Al4V remained on a passive potential range during sliding when coupled to NiCr, while the other materials were not affected by the galvanic couple condition.

Similar content being viewed by others

References

Barros CD, Rocha JC, Bastos IN, Ponciano Gomes JAC (2020) Tribocorrosion of Ti6Al4V and NiCr implant alloys: Effect of galvanic interaction. J Bio Tribo Corros 6:117. https://doi.org/10.1007/s40735-020-00415-1

Barros CDR, Rocha JC, Ferraz BF, Santelli RE, Ponciano Gomes JAC (2020) Galvanic corrosion of Ti6Al4V coupled with NiCr as a dental implant alloy in fluoride solutions. Int J Electrochem Sci 15:394–411. https://doi.org/10.20964/2020.01.07

Apaza-Beyoda K, Tarce M, Benfati CAM, Henriques B, Mathew MT, Teughels W, Souza JCM (2017) Synergistic interactions between corrosion and wear at titanium-based dental implant connections: A scoping review. J Periodont Res 52:946–954. https://doi.org/10.1111/jre.12469

Cruz HV, Souza JCM, Henriques M, Rocha LA (2011) Tribocorrosion and bio-tribocorrosion in the oral environment The case of dental implants. In: Cruz HV, Souza JCM, Henriques M, Rocha LA (eds) Biomedical Tribology. Nova Science Publishers Inc

Alves SA, Bayon R, Viteri VS, Garcia MP, Iagartua A, Fernandes MH, Rocha LA (2015) Tribocorrosion behavior of calcium- and phosphorus- enriched titanium oxide films and study of osteoblast interactions for dental implants. J Bio Tribo Corros 1(23):2–21. https://doi.org/10.1007/s40735-015-0023-y

Souza JCM, Barbosa SL, Ariza E, Celis JP, Rocha LA (2012) Simultaneous degradation by corrosion and wear of titanium in artificial saliva containing fluorides. Wear 292–293:82–88. https://doi.org/10.1016/j.wear.2012.05.030

Golvano I, Garcia I, Conde A, Tato W, Aginagalde A (2015) Influence of fluoride content and pH on corrosion, and tribocorrosion behavior of Ti13Nb13Zr alloy in oral environment. J Mech Behav Biomed Mater 49:186–196. https://doi.org/10.1016/j.jmbbm.2015.05.008

Revathi A, Borrás AD, Muñoz AI, Richard C, Manivasagam G (2017) Degradation mechanisms and future challenges of titanium and its alloys for dental implant applications in oral environment. Mater Sci Eng C 76:1354–1368. https://doi.org/10.1016/j.msec.2017.02.159

Manam NS, Harun WSW, Shri DNA, Ghani SAC, Kurniawan T, Ismail HM, Ibrahim MHI (2017) Study of corrosion in biocompatible metals for implants: A review. J Alloys Compd 701:698–715. https://doi.org/10.1016/j.jallcom.2017.01.196

Dimah MK, Devesa F, Borrás VA, Muñoz AI (2012) Study of the biotribocorrosion behavior of titanium biomedical alloys in simulated body fluids by electrochemical techniques. Wear 294–295:409–418. https://doi.org/10.1016/j.wear.2012.04.014

Vieira AC, Ribeiro AR, Rocha LA, Celis JP (2006) Influence on pH and corrosion inhibitors on the tribocorrosion of titanium saliva. Wear 261:994–1001. https://doi.org/10.1016/j.wear.2006.03.031

Licausi MP, Muñoz AI, Borrás VA (2015) Tribocorrosion mechanisms of Ti6Al4V in artificial saliva by zero-resistance ammetry (ZRA) technique. J Bio Tribo Corros 1(8):1–11. https://doi.org/10.1007/s40735-015-0008-x

Bauer J, Costa JF, Grande CCN, RHM, Loguercio AD, Reis A, (2012) Characterization of two Ni-Cr dental alloys and the influence of casting mode on mechanical properties. J Prosthodont 56:264–271. https://doi.org/10.1016/j.jpor.2012.02.004

Mathew MT, Pai PS, Pourzal R, Fischer A, Wimmer M (2009) Significance of tribocorrosion in biomedical applications overview and current status. Review Article Adv Tribol 1–12:250986. https://doi.org/10.1155/2009/250986

Corne P, March P, Cleymand F, Geringer J (2019) Fretting-corrosion behavior on dental implant connection in human saliva. J Mech Behav Biomed Mater 94:86–92. https://doi.org/10.1016/j.jmbbm.2019.02.025

Branco AC, Moreira V, Reis JA, Colaço R, Figueiredo-Pina CG, Serro AP (2019) Influence of contact configuration and lubricating conditions on the microtriboactivity of the zirconia-Ti6Al4V pair used in dental applications. J Mech Behav Biomed Mater 91:164–173. https://doi.org/10.1016/j.jmbbm.2018.12.009

Zohdi H, Emami M, Shahverdi HR (2012) Galvanic corrosion behavior of dental alloys. In: Valdez Benjamin (ed) Environmental and Industrial Corrosion-Practical and Theoretical Aspects. IntechOpen, US, pp 157–168

Barão VAR, Mathew MT, Assunção WG, Yuan JCC, Wimmer MA, Sukotjo C (2012) Stability of cp-Ti and Ti6Al4V alloy for dental implants as a function of saliva pH – an electrochemical study. Clin Oral Implants Res 23:1055–1062. https://doi.org/10.1111/j.1600-0501.2011.02265.x

ASTM F136-13 (2013) Standard specification for wrought titanium-6aluminum-4vanadium ELI (Extra Low Interstitial) alloy for surgical implant applications (UNS R56401). ASTM International, West Conshohocken, PA

ASTM F67-13 (2017) Standard specification for unalloyed titanium, for surgical implant applications (UNS R50250, UNS R50400, UNS R50550, UNS R50700). ASTM International, West Conshohocken, PA

Rimodini L, Farè S, Brambilla E, Felooni A, Consonni C, Brossa F, Carassi A (1997) The effect of surface roughness on early in vivo plaque colonization of titanium. J Periodont 68:556–562. https://doi.org/10.1902/jop.1997.68.6.556

Bollen C, Lambrechts P, Quiryen M (1997) Comparison of surface roughness of oral hard materials to threshold surface roughness for bacterial plaque retention: a review of the literature. Dent Mater 13:258–269. https://doi.org/10.1016/S0109-5641(97)80038-3

ASTM E384-17 (2017) Standard Test Method for Microindentation Hardness of Materials. ASTM International, West Conshohocken, PA

ASTM G3-14 (2019) Standard Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing. ASTM International, West Conshohocken, PA

ISO 10993-15 (2019) Biological evaluation of medical devices—Part 15: Identification and quantification of degradation products from metals and alloys. International Organization for Standardization, Geneva, Switzerland

Hacisalihoglu I, Samancioglu A, Yildiz F, Purucek G, Alsaran A (2015) Tribocorrosion properties of different type titanium alloys in simulated body fluid. Wear 332–333:679–686. https://doi.org/10.1016/j.wear.2014.12.017

Licausi MP, Muñoz AI, Borrás VA (2013) Influence of the fabrication process and fluoride content on the tribocorrosion behavior of Ti6Al4V biomedical alloy in artificial saliva. J Mech Behav Biomed Mater 20:137–148. https://doi.org/10.1016/j.jmbbm.2013.01.019

Lepicka M, Gradzka- Dahlke M, Pieniak D, Pasierbiewicz K, Krynska K, Niewezaz A (2019) Tribological performance of titanium nitride coatings: A comparative study on Ti-N coated stainless steel and titanium alloy. Wear 422–423:68–80. https://doi.org/10.1016/j.wear.2019.01.029

Mombelli A, Hashim D, Cionca N (2018) What is the importance of titanium particles and biocorrosion on implant survival and complications? A critical review. Clin Oral Implants Res 29:37–53. https://doi.org/10.1111/clr.13305

Barril S, Debaud N, Mischler S, Landolt D (2002) A tribo-electrochemical apparatus for in vitro investigation of fretting-corrosion of metallic implants materials. Wear 252:744–754. https://doi.org/10.1016/S0043-1648(02)00027-3

Faverani LP, Fogaça JF, Machado T, Silva EA, Barão VAR, Assunção WG (2015) Does surface topography improve electrochemical behavior of Ti6Al4V alloy in different saliva pH levels? J Bio Tribo Corros 1:20. https://doi.org/10.1007/s40735-015-0020-1

Sampaio NAS, Silva JW, Acciari HA, Nakazato RZ, Codaro EN, Felipe H (2010) Influence of Ni and Cr content on corrosion resistance of Ni-Cr-Mo alloys for fixed dental prostheses in 0.05% NaF aqueous solution. Mater Sci Appl 1:369–372. https://doi.org/10.4236/msa.2010.16053

Cortada M, Ginger LL, Costa S, Gil FJ, Rodríguez D, Planell JA (2000) Galvanic corrosion behavior of titanium implant coupled to dental alloys. J Mater Sci: Mater Med 11:287–293. https://doi.org/10.1023/A:1008905229522

Borrás AD, Buch AR, Cardete AR, Navarro-Laboulais J, Muñoz AI (2019) Chemo-mechanical effects on the tribocorrosion behavior of titanium/ceramic dental implant pairs in artificial saliva. Wear 426–427:162–170. https://doi.org/10.1016/j.wear.2018.12.052

Mendes TA, Caramês J, Lopes LP, Ramalho AL (2018) Sphere-plane methodology to evaluate the wear of titanium of dental implants: a research proposal. BMC Res Notes 11:259. https://doi.org/10.1186/s13104-018-3635-8

Landolt D, Mischler S, Stemp M, Barril S (2014) Third body effects and material fluxes in tribocorrosion systems involving a sliding contact. Wear 256:517–524. https://doi.org/10.1016/S0043-1648(03)0056-1

Landolt D, Mischler S, Stemp M (2001) Electrochemical methods in tribocorrosion: a critical appraisal. Electrochim Acta 46:3913–3929. https://doi.org/10.1016/S0013-4686(01)00679-X

Cordeiro JM, Beline T, Ribeiro ALR, Rangel EC, Cruz NC, Landers R, Faverani LP, Vaz LG, Fais LM, Vicente FB, Grandini CR, Mathew MT, Sukotjo C, Barão VAR (2017) Development of binary and ternary alloys for dental implants. Dent Mater 33:1244–1257. https://doi.org/10.1016/j.dental.2017.07.013

Papageorgiou N, Bonin A, Espallargas N (2014) Tribocorrosion mechanisms of NiCrMo-625 alloy: An electrochemical modelling approach. Tribol Int 73:177–186. https://doi.org/10.1016/j.triboint.2014.01.018

Espallargas N, Johnsen R, Torres C, Muñoz I (2013) A new experimental technique for quantifying the galvanic coupling effects on stainless steel during tribocorrosion under equilibrium conditions. Wear 307:190–197. https://doi.org/10.1016/j.wear.2013.08.026

Queiroz Neto M, Rainforth WM (2020) Effect of potential and microstructure on the tribocorrosion behaviour of beta and near beta Ti alloys I. Biotribology 24:100141. https://doi.org/10.1016/j.biotri.2020.100141

Acknowledgements

The authors acknowledge the financial support by CNPq, FAPERJ and Fundação Coppetec/Brazil. This investigation was supported in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barros, C.D.d.R., Rocha, J.C., Bastos, I.N. et al. Tribocorrosion Resistance of Dental Implant Alloys—Assessment of cp-Ti, Ti6Al4V, and NiCr in Neutral and Acidified Saliva. J Bio Tribo Corros 7, 73 (2021). https://doi.org/10.1007/s40735-021-00508-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00508-5