Abstract

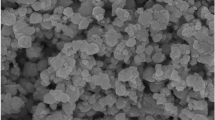

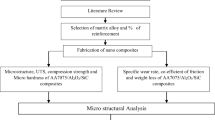

Considerable improvement in weight reduction, strength, wear obstruction, and modulus is the basic in meeting the plan and design criteria for the production of airplane, launch vehicles, and automobiles. This work proposes the low-cost manufacture process involving 2, 4, and 6 wt% AlB2 in-situ particle strengthened with aluminum (Al) Metal Matrix Composites (MMCs) utilizing chemical reaction through exothermic response between halide salt KBF4 and Al matrix at a temperature of 850 °C through vortex technique. The as-cast matrix blend and the in-situ composite were heat treated at a temperature of 535 °C for 1 h accompanied by quenching in various media like ice, oil, and water. The quenched samples were subjected to artificial aging at a temperature of 175 °C for 10 h. Microstructural studies were conducted on the as-cast and in-situ composites for dissemination of AlB2 particles in the as-cast matrix. SEM images affirm the development of AlB2 with uniform circulation in the matrix. X-ray diffractometer test was performed for the formation of AlB2 reinforcement phase in the matrix composite. Wear and mechanical properties were explored for the in-situ composites; for wear test, the impact of sliding rate, applied load, and sliding distance were basic parameters corresponding to the wear experienced by the material. The wear conduct and worn morphology of the aluminum MMCs subjected to various quenchants were additionally evaluated using pin-on-disc tests involving specimens to slide against a hardened steel disc under different load conditions. The exploratory outcomes exhibited that the typical load and fortification proportions were significant variables affecting the volumetric wear rate for all the quenched samples, trailed by sliding speed. The wear resistance behavior is found to be higher for specimens involving ice quenching treatment followed by water and oil-quenched composites.

Similar content being viewed by others

References

Pramod SL, Bakshi SR, Murty BS (2015) Aluminum-based cast in situ composites: a review. J Mater Eng Perform 24:2185–2207

Dayanand S, Satish Babu B (2020) A Review on synthesis of AlB2 reinforced aluminium matrix composites. IOP Conf Ser Mater Sci Eng 810:012038. https://doi.org/10.1088/1757-899X/810/1/012038

Reddy BSB, Das K, Das S (2007) A review on the synthesis of in situ aluminium based composites by thermal, mechanical and mechanical-thermal activation of chemical reactions. J Mater Sci 42:9366–9378

Boppana SB, Dayanand S (2020) Development of AlB2 particles using inorganic halide salts and mechanical characterization of AlB2 reinforced AA6061 MMC’s. Mater Today Proc 27:595–602. https://doi.org/10.1016/j.matpr.2019.12.068

Boppana SB, Dayanand S, Anil Kumar MR, Kumar V, Aravinda T (2020) Synthesis and characterization of nano graphene and ZrO2 reinforced Al 6061 metal matrix composites. J Mater Res Technol 9(4):7354–7362. https://doi.org/10.1016/j.jmrt.2020.05.013

Boppana S, Chennakeshavalu K (2009) Preparation of Al-5Ti master alloys for the in-situ processing of Al-TiC metal matrix composites. J Minrls Mater Char Engg 8(7):563–568. https://doi.org/10.4236/jmmce.2009.87049

Boppana S (2020) In situ synthesis of titanium carbide in pure aluminium. J Mater Sci Chem Engg 8:1–10. https://doi.org/10.4236/msce.2020.81001

Hoseini M, Meratian M (2009) Fabrication of in situ aluminium-alumina composite with glass powder. J Alloys Compd 471:378–382

Karantzails AE, Lekatou A, Gerogties M, Poulas V, Mavros H (2011) Casting based production of Al-TiC-AlB2 composite material through the use of KBF4 salt. J Mater Engg Perform 20(2):198–202

Wang X (2005) The formation of AlB2 in an Al- B master alloy. J Alloys Compd 403:283–287

Maldovan P, Dragut DV (2015) In-situ productions of Al/AlB2 composite by metal salt reaction. Research gate net publication. https://doi.org/10.13140/RG2.1.1339.5367

Boppana SB, Dayanand S, Ramesh S (2020) Effect of reaction holding time on synthesis and characterization of AlB2 reinforced Al6061 metal matrix composites. J Bio Tribo Corros 6:88. https://doi.org/10.1007/s40735-020-00385-4

Kayikcia R, Savas OB, Koksala S, Demira A (2013) The effect of reinforcement ratio on the wear behaviour of AlB2 flake reinforced MMCS. Acta Phys Pol, A 2(125):24–28

Queyreau S, Monnet G, Devincre B (2010) Orowan strengthening and forest hardening superposition examined by dislocation dynamics simulations. Acta Mater 58:5586–5595

Shabestari SG, Shahri F (2004) Influence of modification, solidification conditions and heat treatment on the microstructure and mechanical properties of A356 aluminum alloy. J Mater Sci 39:2023–2032

Pedersen L, Arnberg L (2001) The effect of solution heat treatment and quenching rates on mechanical properties and microstructures in Al-Si-Mg foundry alloys. Metall Mater Trans 32A:525–532

Dorward RC (1997) A dynamic quench model for strength predictions in heat-treatable aluminum alloys. J Mater Process Tech 66:25–29

MacKenzie DS, Newkirk JW (2001) The use of the jominy end quench for determining optimal quenching parameters in aluminum. Proceedings of the 8th Seminar of IFHTSE, Dubrovnik, Croatia 12–14 September. p 139

Prabhu Swamy NR, Ramesh CS, Chandrashekar T (2010) Effect of heat treatment on strength and abrasive wear behaviour of Al6061SiC p composites. Bulletin Mater Sci 33(1):49–54. https://doi.org/10.1007/s12034-010-0007-y

Reddappa HN, Suresh KR, Niranjan HB, Satyanarayana KG (2011) Dry sliding friction and wear behavior of Aluminum/Beryl composites. Inter J Appl Eng Res 2:2

Ramesh D, Swamy RP, Chandrashekar TK (2012) Role of heat treatment on Al6061- frit particulate composites. J Miner Mater Char Eng 11(4):353–363

Manjunatha LH, Dinesh P (2013) Studies on effect of heat treatment and water quench age hardening on microstructure, strength, abrasive wear behaviour of Al6061-MWCNT metal matrix composites. J Acad Indus Res 1(10):595–600

Keshavamurthy R, Madhu Sudhan J, Gowda N, Ananda Krishna R (2016) Effect of thermo-mechanical processing and heat treatment on the tribological characteristics of Al based MMC’s. IOP Conf Ser Mater Sci Eng 149:012118. https://doi.org/10.1088/1757-899X/149/1/012118

Koksal S, Ficici F, Kayikci R, Savas O (2012) Experimental investigation of dry sliding wear behaviour of insitu AlB2/Al composite based on taguchi’s method. Mater Des 42:124–230. https://doi.org/10.1016/j.matdes.2012.05.048

Dayanand S, Satish Babu B, Auradi V (2018) Experimental investigation of microstructure and dry sliding wear behavior of Al-AlB2 metal matrix composites. Mater Today Proc 5(10):22536–22542. https://doi.org/10.1016/j.matpr.2018.06.625

Dayanand S, Boppana SB, Hemanth J, Aravinda T (2019) Microstructure and corrosion characteristics of in situ aluminum diboride metal matrix composites. J Bio Tribo Corros 5:60. https://doi.org/10.1007/s40735-019-0250-8

Boppana SB, Dayanand S (2020) Impact of heat treatment on mechanical, wear and corrosion behaviour of in situ AlB2 reinforced metal matrix composites produced by liquid metallurgy route. J Bio Tribo Corros 6:33. https://doi.org/10.1007/s40735-020-0324-7

Savaş O (2012) Application of taguchi method to investigate the effect of some factors on in-situ formed flake structures of Al/AlB2 composite. Adv Compos Lett 21(2):49

Ferrict F (2011) Investigation of unlubricated sliding wear behaviour of in situ AlB2–Al metal matrix composite. Adv Compos Lett 20:4

Elecicek H, Savas O, Aydin Z, Ozdemir OK, Kayikci R (2015) Corrosion behavior of inistu AlB2/Al-Cu metal matrix composites. Acta Physia Polonica A 129(4):661–664

Youn L, Han J, Liu J, Jiang Z (2016) Mechanical properties and tribological behaivour of aluminium matrix composites reinforced with inistu AlB2 particles. Tribol Inter 98:41–47. https://doi.org/10.1016/j.triboint.2016.01.046

Radhika N, Raghu R (2016) Effect of abrasive medium on wear behavior of Al/AlB2 functionally graded aluminium matrix composites. Tribology Japan Soc Tribo 11(3):487–493

Dumitru (2011) Characterization of in situ AA6061/AlB2 metal matrix composite. U.P.B.SCI.BULL., Series B, 73(1454–2331)

Auradi V, Kori SA (2008) Influence of reaction temperature for the manufacturing of Al-3Ti and Al-3B master alloys. J Alloys Compd 45:147–156

Anwarkhan AR, Ramesh CS, Ramachandra A (2002) Heat treatment of Al6061-SiC composites. Proceedings of international companies on manufacturing. ICM, Dhaka, pp 21–28

Hansen N (2004) Hall-Petch relation and boundary strengthening. Scripta Mater 51(8):801–806

Cottu JP, Couderc JJ, Viguier B, Bernard L (1992) Influence of SiC reinforcement on precipitation and hardening of a metal matrix composite. J Mater Sci 27:3068–3074

Zhang Z, Chen DL (2008) Contribution of Orowan strengthening effect in particulate reinforced metal matrix nanocomposites. Mater Sci Eng A 483:148–152

Rajesh AM, Kaleemulla MK, Doddamani S (2019) Effect of heat treatment on wear behavior hybrid aluminium metal matix composites. Tribo Indus 41(3):344–354

Bhat S, Mahesh BS (2014) Effect of heat treatment on microstructure and mechanical properties of Al-FA-SiC hybrid MMCS. Inter J Innov Res Sci Eng Tech 3:6

Rajan TV, Sharma CP, Sharma A (1998) Heat treatment principles techniques. Rajkamal Electric Press, Delhi

Ramesh CS, Ahamed A, Channabasappa BH, Keshavamurthy R (2010) Development of Al 6063-TiB2 in situ composites. Mater Des 31:2230–2236

Gautam G, Mohan A (2015) Effect of ZrB2 particles on the microstructure and mechanical properties of hybrid (ZrB2+Al3Zr)/AA5052 in situ composites. J Alloys Compd 649:174–183

Zhang SL, Zhao Y, Chen G, Cheng XN, Huo XY (2008) Fabrication and dry sliding wear behavior of in situ Al-K2ZrF6-KBF4 composites reinforced by Al3Zr and ZrB2 particles. J Alloy Compd 450:185–192

Dinaharan I, Murugan N, Parameswaran S (2011) Influence of in situ formed ZrB2 particles on microstructure and mechanical properties of AA6061 metal matrix composites. Mater Sci Eng A 528:5733–5740

Golshahr A, Elango Natarajan MS, Santhosh R, Sasikumar SR, Durairaj R (2018) Multi wall carbon nanotube reinforced silicone for aerospace applications. Int J Mech Prod Eng Res Dev 8(4):743–752

Ramesh S, Govindaraju N, Suryanarayan CP (2018) Investigation on mechanical and fatigue behaviour of aluminium based SiC/ZrO2 particle reinforced MMC. IOP Conf Ser Mater Sci Eng 346:012030

Acknowledgements

The authors wish to thank JIT and BMS College of Engineering, Bangalore for helping in providing SEM, EDS, and XRD equipment facility. They also wish to thank Visvesvaraya Technological University, Belagavi for their support to carry out the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dayanand, S., Boppana, S.B., Auradi, V. et al. Evaluation of Wear Properties of Heat-Treated Al-AlB2 in-situ Metal Matrix Composites. J Bio Tribo Corros 7, 40 (2021). https://doi.org/10.1007/s40735-021-00476-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-021-00476-w