Abstract

This work presents a new analytical method to estimate COF in THF using tube-upsetting method. Mathematical model presented in Rudraksha and Gawande (J Bio- and Tribo-Corros 3(4): 1–13, 2017. https://doi.org/10.1007/s40735-017-9) is used to estimate COF in tube hydroforming. From investigations, it is observed that COF can be determined using geometrical parameters of the given tube, optimized pressure, and thickness of tube. In this paper, influence of friction on different process parameters such as material properties, geometrical parameters and variation in thickness of tube has been analyzed theoretically and experimentally. The proposed method is verified by analytical and experimental approach.

Similar content being viewed by others

References

Plancak M, Vollertsen F, Woitschig J (2005) Analysis, finite element simulation and experimental investigation of friction in tube hydroforming. J Mater Process Technol 170:220–228

Ngail G, Gariety M, Altan T (2006) Enhancing tribological conditions in tube hydroforming by using textured tubes. J Tribol 128:674–680

Rudraksha SP, Gawande SH (2017) Optimization of process parameters to study the influence of the friction in tube hydroforming. J Bio- and Tribo-Corros 3(4):1–13. https://doi.org/10.1007/s40735-017-9

Fuchizawa S (1984) Influence of strain hardening exponent on the deformation of thin-walled tube of finite length subjected to hydrostatic internal pressure. Int Proc Conf Adv Technol Plast 1:297–302

Orban H, JackHu S (2007) Analytical modeling of wall thinning during corner filling in structural tube hydroforming. J Mater Process Technol 194(1–3):7–14. https://doi.org/10.1016/j.jmatprotec.2007.03.112

Kridli GT, Bao PLP, Mallick PK, Tian Y (2003) Investigation of thickness variation and corner filling in tube hydroforming. J Mater Process Technol 133(3):287–296

Lianfa Y, Cheng G (2008) Determination of stress–strain relationship of tubular material with hydraulic bulge test. Thin-Walled Struct 46(2):147–154

Muammer K, Eren B, Ömer Necati C (2011) An experimental study on the comparative assessment of hydraulic bulge test analysis methods. Mater Des 32(1):272–281

Kwan C-T, Lin F-C (2003) Investigation of T-shape tube hydroforming with finite element method. Int J Adv Manuf Technol 21(6):420–425

Tirosh J, Neuberger A, Shirizly A (1996) On tube expansion by internal fluid pressure with additional compressive stress. Int J Mech Sci 38(8–9):839–851. https://doi.org/10.1016/0020-7403(95)00113-1

Carleer B, Van der Kevie G, de Winter L, Van Veldhuizen B (2000) Analysis of the effect of material properties on the hydroforming process of tubes. J Mater Process Technol 104:158–166

Shi Y, Jin H, Wu PD, Lloyd DJ (2017) Effects of superimposed hydrostatic pressure on necking and fracture of the tube under hydroforming. Int J Solids Struct 113(114):209–217

Muammer K, Allen T, Suwat J, Altan T (2000) The use of FEA and design of experiments to establish design guidelines for simple hydroformed parts. Int J Mach Tools Manuf 40(15):2249–2266

Chen F, Wang S, Lin R (2007) A study of forming pressure in the tube-hydroforming process. J Mater Process Technol. 192–193:404–440

Kim S, Kim Y (2002) Analytical study for tube hydroforming. J Mater Process Technol 128:232–239

Jansson M, Nilsson L, Simonsson K (2007) On process parameter estimation for the tube hydroforming process. J Mater Process Technol 190(1–3):1–11. https://doi.org/10.1016/j.jmatprotec.2007.02.050

Nikhare C, Weiss M, Hodgson PD (2017) Buckling in low pressure tube hydroforming. J Manuf Process 28:1–10

Kang BH, Lee MY, Shon SM, Moon YH (2005) Forming various shapes of tubular bellows using a single-step hydroforming process. J Mater Process Technol 160:24–33

Manabe K, Amino M (2002) Effects of process parameters and material properties on deformation process in tube hydroforming. J Mater Process Technol 123:285–291

Limb ME, Chakrabarty J, Garber S, Mellor B (1973) The forming of axisymmetric and asymmetric components from tube. In: Proceedings of the 14th International MTDR Conference, Palgrave, London, pp. 799–805. https://doi.org/10.1007/978-1-349-01921-2_102

Ngaile G, Jaeger S, Altan T (2004) Lubrication in tube hydroforming (THF) part II. Performance evaluation of lubricants using LDH test and pear-shaped tube expansion test. J Mater Process Technol 146:116–123

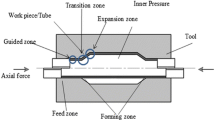

Ngaile G, Jaeger S, Altan T (2004) Lubrication in tube hydroforming (THF) Part I. Lubrication mechanism and development of model tests to evaluate lubricants and die coatings in the transition and expansion zones. J Mater Process Technol 146(11):108–115. https://doi.org/10.1016/S0924-0136(03)00850-1

Lee BH, Keum YT, Wagoner RH (2002) Modeling of the friction caused by lubrication and surface roughness in sheet metal forming. J Mater Process Technol 130–131:60–63

Hwang YM, Huang LS (2005) Friction test in tube hydroforming. Proc Inst Mech Eng B J Eng Manuf 219(8):587–593. https://doi.org/10.1243/095440505X32517

Rudraksha SP, Gawande SH (2020) Influence of lubricants on coefficient of friction in tube hydroforming. J Bio- and Tribo-Corros 6(1):1–14. https://doi.org/10.1007/s40735-019-0309-6

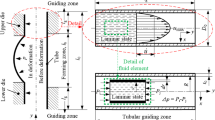

He Z, Yuan S, Yuan S, Li L, Fan X (2012) Reduction of friction in the guiding zone during tube hydroforming. Proc Inst Mech Eng B J Eng Manuf 226(7):1275–1280

Venkateshwar Reddy P, Veerabhadra Reddy B, Janaki Ramulu P (2020) An investigation on tube hydroforming process considering the effect of frictional coefficient and corner radius. Adv Mater Process Technol 6(1):84–103

Funding

This work is not supported fully or partially by any funding organization or agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rudraksha, S.P., Gawande, S.H. Study on Influence of Friction on Process Parameters in Tube Hydroforming. J Bio Tribo Corros 6, 82 (2020). https://doi.org/10.1007/s40735-020-00374-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00374-7