Abstract

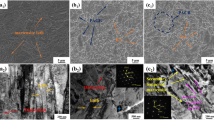

Failure of components made from ASTM A36 mild steel, due to corrosion and biofouling, has been a global menace in recent times. This study aims at evaluating the biofouling—corrosion properties of mild steel by developing a protective thin film of Zn-ZnO composite to protect it. Two plates (40 × 20 × 2) mm3, of commercially obtained steel samples, were prepared in order using sulphate electrolyte for perfect homogenization at a stirring rate of 250 rpm, pH of 4.5, with a current density of 2 A/cm3. The developed composites were characterised using the scanning electron microscopy (SEM) coupled with energy-dispersive spectroscopy (SEM/EDS) for structural evolution. Their electrochemical degradation behaviour of the composite coating was studied using coastal seawater from the Atlantic Ocean using the potentiodynamic polarization method. From the results, the resilient coherent structure of the Zn-ZnO composite provides uniform crystal grain particulates, which are stable and defect-free. The corrosion—biofouling progression shows a pitting-free surface and less corrosion rate of 3.21 mm/years. No doubt, the coating is predominantly stable and could be applied for biofouling and corrosion application.

Similar content being viewed by others

References

Abioye OP, Loto CA, Fayomi OSI (2019) Evaluation of anti-biofouling progresses in marine application. J Bio Tribo Corros 5(1):22

Fayomi OSI, Popoola API (2015) Anti-corrosion and tribo-mechanical properties of co-deposited Zn–SnO2 composite coating. Acta Metall Sin (English Letters) 28(4):521–530

Loto CA, Loto RT (2018) Effect of combined trisaminomethane and hexadecyltrimethyl ammonium bromide (Hdtab) inhibitors on mild steel in nitric acid. Orient J Chem 34(3):1551–1558

Ajayi OO, Omowa OF, Omotosho OA, Abioye OP, Akinlabi ET, Akinlabi SA, Abioye AA, Owoeye FT, Afolalu SA (2018) Experimental investigation of the effect of ZnO-citrus sinensis nano-additive on the electrokinetic deposition of zinc on mild steel in acid chloride. TMS annual meeting & exhibition. Springer, Cham, pp 35–40

Praveen BM, Venkatesha TV (2011) Electrodeposition and corrosion resistance properties of Zn-Ni/TiO2 nano composite coating. Int J Electrochem 261:407–410

Fayomi OSI (2015) Chemical interaction, interfacial effect and the microstructural characterization of the induced zinc–aluminum–Solanum tuberosum in chloride solution on mild steel. Res Chem Intermed 41(4):2393–2405

PraveenKumar CM, Venkatesha TV, Vathsala K, Nayana KO (2012) Electrodeposition and corrosion behavior of Zn–Ni and Zn–Ni–Fe2O 3 coatings. J Coat Technol Res 9(1):71–77

Praveen BM, Venkatesha TV (2008) Electrodeposition and properties of Zn-nanosized TiO2 composite coatings. Appl Surf Sci 254(8):2418–2424

Talbot DE, Talbot JD (2018) Corrosion science and technology. CRC Press, Boca Raton

Jones DRH, Ashby MF (2012) Engineering materials 2: an introduction to microstructures and processing. Butterworth-Heinemann, Oxford

Riskin J, Khentov A (2019) Electrocorrosion and protection of metals. Elsevier, Amsterdam, pp 3–47

Vanysek P (2000) Electrochemical series. In: CRC handbook of chemistry and physics. CRC Press, LLC, p 8

Perez N (2004) Electrochemistry and corrosion science, vol 412. Kluwer Academic Publishers, Boston

Gu JD (2018) Microbial biofilms, fouling, corrosion, and biodeterioration of materials. In: Myer K (ed) Handbook of environmental degradation of materials. William Andrew Publishing, Norwich, pp 273–298

Varin KJ, Lin NH, Cohen Y (2013) Biofouling and cleaning effectiveness of surface nanostructured reverse osmosis membranes. J Membr Sci 446:472–481

Yoon H, Baek Y, Yu J, Yoon J (2013) Biofouling occurrence process and its control in the forward osmosis. Desalination 325:30–36

Al-Juboori RA, Yusaf T (2012) Biofouling in RO system: mechanisms, monitoring and controlling. Desalination 302:1–23

Yebra DM, Kiil S, Dam-Johansen K (2004) Antifouling technology—past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog Org Coat 50(2):75–104

Abbott A, Abel PD, Arnold DW, Milne A (2000) Cost–benefit analysis of the use of TBT: the case for a treatment approach. Sci Total Environ 258(1–2):5–19

Shaw BA, Kelly RG (2006) What is corrosion? Interface Electrochem Soc 15(1):24–27

Fayomi OSI, Akande IG, Abioye OP, Fakehinde OB (2019) New trend in thin film composite coating deposition: a mini review. Procedia Manuf 35:1007–1012

Javaherdashti R, Alasvand K (2019) Biological treatment of microbial corrosion: opportunities and challenges. Elsevier, Amsterdam, pp 11–24

Zhang SD, Wu J, Qi WB, Wang JQ (2016) Effect of porosity defects on the long-term corrosion behaviour of Fe-based amorphous alloy coated mild steel. Corros Sci 110:57–70

Morgan TD, Wilson M (2001) The effects of surface roughness and denture acrylic on biofilm formation by Streptococcus oralis in a constant depth film fermenter. J Appl Microbiol 91:47–53

Rusu DE, Ispas A, Bund A, Gheorghies C, Carac G (2012) Corrosion tests of nickel coatings prepared from a Watts-type bath. J Coat Technol Res 9(1):87–95

Fayomi OSI, Kanyane LR, Monyai T (2017) Development of reinforced in-situ anti-corrosion and wear Zn-TiO2/ZnTiB2 coatings on mild steel. Results in physics 7:644–650

Acknowledgements

Our genuine appreciation goes to Covenant University, which has provided the financial support required for this study to come to a reality. Also, we appreciate the Department of Chemical and Materials Engineering, Tshwane University of Technology, and Department of Mechanical Engineering, University of Johannesburg, for providing the equipment used for the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Ethics Approval

This work has no ethical issues.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abioye, O.P., Fayomi, O.S.I. & Loto, C.A. Electrochemical Study of Co-Deposited Zn-ZnO on ASTM A36 Mild Steel for Marine Application. J Bio Tribo Corros 6, 74 (2020). https://doi.org/10.1007/s40735-020-00371-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00371-w