Abstract

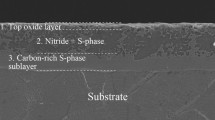

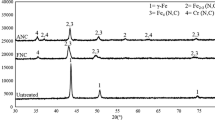

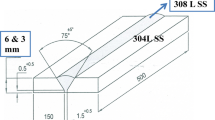

Stainless steel is mostly used in applications where resistance to corrosion is of prime importance. The surface-treated stainless steels are widely used in many applications. AISI304 stainless steel has a low surface hardness and a relatively high wear rate. AISI304 stainless steel bar and Tungsten (W) were chosen as the substrate and the alloying material, respectively. The W powder was pasted over the surface of the AISI304 stainless steel using a PVA binder. The surface modification process was carried out using the heat generated by a Gas Tungsten Arc (GTA). The corrosion behavior of substrate and surface alloyed. AISI304 stainless steel was studied using the TAFEL polarization test. The corrosion was studied in Hanks balance salt solution. The study revealed that pitting corrosion occurs on the surface of the specimens, but Icorr value increased by an order of magnitude two. The increase in corrosion current is attributed to the formation of the oxides, and carbides formed in the surface of the modified layer. This implies that surface alloying with W enhances the corrosion resistance of the AISI304 stainless steel. The investigation concludes that the surface alloying process with W using GTA is effective for modifying the surface properties of AISI304 stainless steel.

Similar content being viewed by others

References

Narayanan V, Saravanan R, Sellamuthu R (2016) An investigation on the hardness and wear rate of surface alloyed AISI304 stainless steel with Ti using GTA as heat source. Indian J Sci Technol 9:16

Krishnakumar M, Saravanan R, Sellamuthu R, Vijaynarayan (2018) Microstructure, hardness and wear rate of heat treated titanium surface alloyed AISI 304 stainless steel. Mater Today Proc 5:7571–7576

Jonasova L, Muller FA, Helebrant A, Strnad J, Greil P (2004) Hydroxyapatite formation on alkali-treated titanium with different content of Na+ in the surface layer. Biomaterial 25:1187

Brenemark PI, Prosthet J (1986) Osseointegration in skeletal reconstruction and rehabilitation: a review. Dentistry 50:399

Barragán F, Guardián R, Menchaca C, Rosales I, Uruchurtu J (2010) Electrochemical corrosion of hot pressing titanium coated steels for biomaterial applications. Int J Electrochem Sci 5:1799–1809

Chen JY, Yu GP, Huang JH (2000) Corrosion beaviour and adhersion of ion-plated TiN film on AISI 304 Stainless steel. Mater Chem Phys 65:310–315

Chang YY, Wang DY (2005) Corrosion behavior of electroless nickel-coated AISI 304 stainless steel enhanced by titanium ion implantation. Surf Coat Technol 200:2187–2191

Warikh M, Rashid A, Miron G, Zulkifli MR, Asyadi Azam M (2012) Formation of Cr23C6 during the sensitization of AISI 304 stainless steel and its effect to pitting corrosion. Int J Electrochem Sci 7:9465–9477

Chou WJ, Ping G, Huang JH (2001) Corrosion behavior of TiN-coated 304 stainless steel. Corros Sci 43:2023–2035

Rudenja S, Leygraf C, Pan J, Kulu P, Talimets E, Mikli V (1999) Duplex TiN cotings deposited by arc palting for increased corrosion resistance of stainless steel substrate. Surf Coat Technol 114:126–136

Feng H, Jiang Z, Li H, Lu P, Zhang S, Zhu H, Zhang B, Zhang T, Xu D, Chen Z (2018) Investigation of microbiologically influenced corrosion of the high nitrogen nickel-free stainless steel by Pseudomonas aeruginosa. Corros Sci. https://doi.org/10.1016/j.corsci.2018.09.002

Conde AA, Garica I, de Damborenea JJ (2001) Pitting corrosion of 304 stainless steel after laser surface melting in argon and nitrogen atmospheres. Corros Sci 43(5):828–871

Majumdar JD, Manna I (1999) Laser surface alloying of AISI 304-stainless steel with molybdenum for improvement in pitting and erosion–corrosion resistance. Mater Sci Eng A 267:50–59

Xiong Y, Smugeresky JE, Schoenung JM (2009) The influence of working distance on laser deposited WC–Co. Mater Process Technol 209:4935–4941

Anandan S, Pityana S, Majumdar JD (2012) Structure–property-correlation in laser surface alloyed AISI 304 stainless steel with WC + Ni + NiCr. Mater Sci Eng A 536:159–169

Chakraborty A, Pityana S, Majumdar JD (2017) Laser surface alloying of AISI 304 stainless steel with WC+Co+NiCr for improving wear resistance. Proc Manuf 7:8–14

Krishnakumar M, Saravanan R (2019) Impact of tungsten on microstructure, hardness and wear rate of AISI 304 stainless steel surface alloyed under nitrogen environment. Mater Res Express 6:086571

Fan C, Li H, Kecskes LJ, Tao K, Choo H, Liaw PK, Liu CT (2006) Mechanical behavior of bulk amorphous alloys reinforced by ductile particles at cryogenic temperatures. Phys Rev Lett 96(14):145506

Fontana MG (1986) Corrosion engineering. McGraw-Hill, New York

Callister WD (2012) Materials science, and engineering. Wiley, Amsterdam, pp 361–362

Drogowska M, Meanard H, Brossard L (1997) Pitting of AISI 304 stainless steel in bicarbonate and chloride solutions. J Appl Electrochem 27:169–177

Ramalingam VV, Ramasamy P (2017) Modelling corrosion behavior of friction stir processed aluminium alloy 5083 using polynomial: radial basis function. Trans Indian Inst Met 70:2575–2589

Vaira Vignesh R, Padmanaban R, Datta M (2018) Influence of FSP on the microstructure, microhardness, intergranular corrosion susceptibility and wear resistance of AA5083 alloy. Tribol-Mater Surf Interfaces 12:157–169

Song GL, Atrens A (1999) Understanding magnesium corrosion—a framework for improved alloy performance. Adv Eng Mater 1:11–33

Zeng RC, Wang L, Zhang DF, Cui HZ, Han EH (2014) In vitro corrosion of Mg-6Zn-1Mn-4Sn-1.5Nd/0.5Y alloys. Front Mater Sci 8:230–243

Ghali E, Dietzel W, Kainer K-U (2004) General and localized corrosion of magnesium alloys: a critical review. J Mater Eng Perform 13:7–23

Pourbaix M (2012) Lectures on electrochemical corrosion. Springer Science & Business Media, Berlin

Stansbury EE, Buchanan RA (2000) Fundamentals of elecrochemical corrosion. ASM International, Ohio

Fontana MG (2001) Corrosion engineering. McGraw Hill Education, New York

Fontana MG (2005) Corrosion engineering. Tata McGraw-Hill Education, New York

Marcus P (2011) Corrosion mechanisms in theory and practice. CRC Press, Boca Raton, FL

Kelly RG, Scully JR, Shoesmith D, Buchheit RG (2002) Electrochemical techniques in corrosion science and engineering. CRC Press, Boca Raton, FL

Schulte F (1976) A theory of thin metal films: electron density, potentials and work function. Surf Sci 55:427–444

Acknowledgements

The author would like to express heart-full gratitude to Dr. R. Sellamuthu Ph.D., Professor, Department of Mechanical Engineering, Amrita School of Engineering, deserves special thanks for the encouragement and advice throughout the work, and sincere gratitude for his constant support. The author would like to thank all the faculties, lab assistant and office staff of the Department of Mechanical Engineering of our School of Engineering for their help and support to carry out this work successfully.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Krishnakumar, M., Saravanan, R. & Narayanan, V. Effect of Bio-Fluid on the Corrosion Properties of Tungsten Surface Alloyed Under Nitrogen on Austenitic Stainless Steel. J Bio Tribo Corros 6, 77 (2020). https://doi.org/10.1007/s40735-020-00369-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00369-4