Abstract

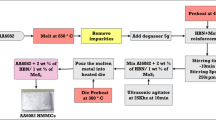

Mainly used in the automotive and aircraft industries, Al–Si-based metal matrix composites stand out with their superior tribological properties under difficult operating conditions. Machinability studies were carried out to prevent and solve the problems that may occur during the shaping of these materials. It is important to improve these composites' machinability performance and environmental impact during machining. Traditional machining fluids have a harmful effect on the environment and human life. It is critical to utilize alternate cutting fluids to eliminate these consequences. It is seen that the studies on this subject are insufficient. In this study, Al–12Si-based composites reinforced with hybrid reinforcements were milled under sustainable cooling/lubrication conditions. According to the results obtained, with cryo-LN2 assisted cooling, surface roughness, tool wear, and cutting temperature were reduced, resulting in better performance than dry machining. It was also determined that energy consumption was reduced with cryo-LN2 compared to dry machining. As a result, the cryogenic cooling technique proved to be the best option for the sustainable manufacturing of Al–12Si-based hybrid composites.

Similar content being viewed by others

Data availability

Data sharing does not apply to this article as no datasets were generated or analyzed during the current study.

References

Liu, Y., Gong, H., He, Y., Zhang, T., Sun, Y., & Liu, X. (2022). Research on machining deformation of 7050 aluminum alloy aircraft rib forging. International Journal of Precision Engineering and Manufacturing, 23(5), 533–543.

Rahi, D. K., & Dubey, A. K. (2022). Evaluation of machining performance for electrochemical surface grinding of aluminium based hybrid MMC. International Journal of Precision Engineering and Manufacturing, 23(9), 1039–1047.

Şap, S., Uzun, M., Usca, Ü. A., Pimenov, D. Y., Giasin, K., & Wojciechowski, S. (2022). Investigation of machinability of Ti–B-SiCp reinforced Cu hybrid composites in dry turning. Journal of Materials Research and Technology, 18, 1474–1487.

Zhang, Z., Zhang, Y., Lin, L., Wu, J., Yu, H., Pan, X., et al. (2021). Study on productivity and aerosol emissions of magnetic field-assisted EDM process of SiCp/Al composite with high volume fractions. Journal of Cleaner Production, 292, 126018.

Bhushan, R. K. (2013). Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. Journal of Cleaner Production, 39, 242–254.

Şap, S., Usca, Ü. A., Tarih, Y. S., Yar, A., Kuntoğlu, M., & Gupta, M. K. (2023). Novel use of cellulose based biodegradable nano crystals in the machining of PPS composites: An approach towards green machining. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-023-00529-0

Gajrani, K. K. (2020). Assessment of cryo-MQL environment for machining of Ti–6Al–4V. Manufacturing Process, 60, 494–502.

Khanna, N., Shah, P., Wadhwa, J., Pitroda, A., Schoop, J., & Pusavec, F. (2021). Energy consumption and lifecycle assessment comparison of cutting fluids for drilling titanium alloy. Procedia CIRP, 98, 175–180.

Shah, P., Khanna, N., Maruda, R. W., Gupta, M. K., & Krolczyk, G. M. (2021). Life cycle assessment to establish sustainable cutting fluid strategy for drilling Ti–6Al–4V. SM&T, 30, e00337.

Chetan, G. S., & Rao, P. V. (2019). Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy. Journal of Cleaner Production, 231, 1036–1049.

Khanna, N., Agrawal, C., Pimenov, D. Y., Singla, A. K., Machado, A. R., da Silva, L. R. R., et al. (2021). Review on design and development of cryogenic machining setups for heat resistant alloys and composites. Manufacturing Process, 68, 398–422.

Mia, M., Morshed, M. S., Kharshiduzzaman, M., Razi, M. H., Mostafa, M. R., Rahman, S. M. S., et al. (2018). Prediction and optimization of surface roughness in minimum quantity coolant lubrication applied turning of high hardness steel. Measurement, 118, 43–51.

Khanna, N., Shah, P., Sarikaya, M., & Pusavec, F. (2022). Energy consumption and ecological analysis of sustainable and conventional cutting fluid strategies in machining 15–5 PHSS. SM&T, 32, e00416.

Khanna, N., Shah, P., Suri, N. M., Agrawal, C., Khatkar, S. K., Pusavec, F., et al. (2021). Application of environmentally-friendly cooling/lubrication strategies for turning magnesium/SiC MMCs. SILICON, 13(8), 2445–2459.

Sharma, V. S., Dogra, M., & Suri, N. M. (2009). Cooling techniques for improved productivity in turning. International Journal of Machine Tools and Manufacture, 49(6), 435–453.

Tai, B. L., Stephenson, D. A., Furness, R. J., & Shih, A. J. (2014). Minimum quantity lubrication (MQL) in automotive powertrain machining. Procedia CIRP, 14, 523–528.

Pervaiz, S., Anwar, S., Qureshi, I., & Ahmed, N. (2019). Recent advances in the machining of titanium alloys using minimum quantity lubrication (MQL) based techniques. International Journal of Precision Engineering and Manufacturing, 6(1), 133–145.

Murthy, K. S., & Rajendran, I. G. (2012). Prediction and analysis of multiple quality characteristics in drilling under minimum quantity lubrication. Proceedings of the Institution of Mechanical Engineers - Part B: Journal of Engineering Manufacture, 226(6), 1061–1070.

Sarıkaya, M., Gupta, M. K., Tomaz, I., Pimenov, D. Y., Kuntoğlu, M., Khanna, N., et al. (2021). A state-of-the-art review on tool wear and surface integrity characteristics in machining of superalloys. CIRP Journal of Manufacturing Science and Technology, 35, 624–658.

Khanna, N., Shah, P., de Lacalle, L. N. L., Rodríguez, A., & Pereira, O. (2021). In pursuit of sustainable cutting fluid strategy for machining Ti–6Al–4V using life cycle analysis. SM&T, 29, e00301.

Khan, M. M. A., Mithu, M. A. H., & Dhar, N. R. (2009). Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. Journal of Materials Processing Technology, 209(15), 5573–5583.

Roushan, A., Rao, U. S., Patra, K., & Sahoo, P. (2022). Performance evaluation of tool coatings and nanofluid MQL on the micro-machinability of Ti-6Al-4V. Manufacturing Process, 73, 595–610.

Jadam, T., Rakesh, M., & Datta, S. (2020). Machinability of Ti–6Al–4V superalloy: Performance of dry cutting and nanofluid MQL (MWCNT-added rice bran oil). Arabian Journal for Science and Engineering, 45(7), 5673–5695.

Şap, S. (2023). Understanding the machinability and energy consumption of Al-based hybrid composites under sustainable conditions. Lubricants, 11(3), 111.

Gupta, M. K., Song, Q., Liu, Z., Sarikaya, M., Jamil, M., Mia, M., et al. (2020). Ecological, economical and technological perspectives based sustainability assessment in hybrid-cooling assisted machining of Ti–6Al–4V alloy. SM&T, 26, e00218.

Balasubramanian, S., Gupta, M. K., & Singh, K. K. (2012). Cryogenics and its application with reference to spice grinding: A review. Critical Reviews in Food Science and Nutrition, 52(9), 781–794.

Shokrani, A., Dhokia, V., & Newman, S. T. (2016). Investigation of the effects of cryogenic machining on surface integrity in CNC end milling of Ti–6Al–4V titanium alloy. Manufacturing Process, 21, 172–179.

Pereira, O., Celaya, A., Urbikaín, G., Rodríguez, A., Fernández-Valdivielso, A., & Lacalle, L. NLd. (2020). CO2 cryogenic milling of Inconel 718: Cutting forces and tool wear. Journal of Materials Research and Technology, 9(4), 8459–8468.

Yap, T. C. (2019). Roles of cryogenic cooling in turning of superalloys, ferrous metals, and viscoelastic polymers. Technologies, 7(3), 63.

Souflas, T., Bikas, H., Ghassempouri, M., Salmi, A., Atzeni, E., Saboori, A., et al. (2022). A comparative study of dry and cryogenic milling for Directed Energy Deposited IN718 components: Effect on process and part quality. International Journal of Advanced Manufacturing Technology, 119(1), 745–758.

Thakur, D. G., Ramamoorthy, B., & Vijayaraghavan, L. (2015). Effect of posttreatments on the performance of tungsten carbide (K20) tool while machining (turning) of Inconel 718. International Journal of Advanced Manufacturing Technology, 76(1), 587–596.

Rodríguez, A., Calleja, A., de Lacalle, L. N. L., Pereira, O., Rubio-Mateos, A., & Rodríguez, G. (2021). Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling. Manufacturing Process, 64, 58–66.

Kalyan Kumar, K. V. B. S., & Choudhury, S. K. (2008). Investigation of tool wear and cutting force in cryogenic machining using design of experiments. Journal of Materials Processing Technology, 203(1), 95–101.

Gupta, M. K., Korkmaz, M. E., Sarıkaya, M., Krolczyk, G. M., Günay, M., & Wojciechowski, S. (2022). Cutting forces and temperature measurements in cryogenic assisted turning of AA2024-T351 alloy: An experimentally validated simulation approach. Measurement, 188, 110594.

Gupta, M. K., Korkmaz, M. E., Sarıkaya, M., Krolczyk, G. M., & Günay, M. (2022). In-process detection of cutting forces and cutting temperature signals in cryogenic assisted turning of titanium alloys: An analytical approach and experimental study. Mechanical Systems and Signal Processing, 169, 108772.

Şap, E., Usca, U. A., Gupta, M. K., & Kuntoğlu, M. (2021). Tool wear and machinability investigations in dry turning of Cu/Mo-SiCp hybrid composites. International Journal of Advanced Manufacturing Technology, 114(1), 379–396.

Şirin, Ş, Yıldırım, Ç. V., Kıvak, T., & Sarıkaya, M. (2021). Performance of cryogenically treated carbide inserts under sustainable cryo-lubrication assisted milling of Inconel X750 alloy. SM&T, 29, e00314.

Basheer, A. C., Dabade, U. A., Joshi, S. S., Bhanuprasad, V. V., & Gadre, V. M. (2008). Modeling of surface roughness in precision machining of metal matrix composites using ANN. Journal of Materials Processing Technology, 197(1), 439–444.

Grzesik, W. (2016). Prediction of the functional performance of machined components based on surface topography: State of the art. Journal of Materials Engineering and Performance, 25(10), 4460–4468.

Wang, X., Yu, T., Dai, Y., Shi, Y., & Wang, W. (2016). Kinematics modeling and simulating of grinding surface topography considering machining parameters and vibration characteristics. International Journal of Advanced Manufacturing Technology, 87(9), 2459–2470.

Giasin, K., Ayvar-Soberanis, S., & Hodzic, A. (2016). Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining GLARE laminates using design of experiments. Journal of Cleaner Production, 135, 533–548.

Kaynak, Y., Lu, T., & Jawahir, I. S. (2014). Cryogenic machining-induced surface integrity: A review and comparison with dry, MQL, and flood-cooled machining. Machining Science and Technology, 18(2), 149–198.

Şap, S., Usca, Ü. A., Uzun, M., Kuntoğlu, M., Salur, E., & Pimenov, D. Y. (2022). Investigation of the effects of cooling and lubricating strategies on tribological characteristics in machining of hybrid composites. Lubricants, 10(4), 63.

Kuntoğlu, M. (2022). Measurement and analysis of sustainable indicators in machining of Armox 500T armor steel. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 236(13), 7330–7349.

Kaynak, Y., & Gharibi, A. (2018). Progressive tool wear in cryogenic machining: The effect of liquid nitrogen and carbon dioxide. Journal of Manufacturing and Materials Processing, 2(2), 31.

Zhou, J. M., Andersson, M., & Stahl, J. E. (2003). The monitoring of flank wear on the CBN tool in the hard turning process. International Journal of Advanced Manufacturing Technology, 22(9), 697–702.

Sen, B., Hussain, S. A. I., Gupta, M. K., Mia, M., & Mandal, U. K. (2021). Swarm intelligence based selection of optimal end-milling parameters under minimum quantity nano-green lubricating environment. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 235(23), 6969–6983.

Wang, F., Li, L., Liu, J., & Shu, Q. (2017). Research on tool wear of milling nickel-based superalloy in cryogenic. International Journal of Advanced Manufacturing Technology, 91(9), 3877–3886.

Patel, T., Khanna, N., Yadav, S., Shah, P., Sarikaya, M., Singh, D., et al. (2021). Machinability analysis of nickel-based superalloy Nimonic 90: A comparison between wet and LCO2 as a cryogenic coolant. International Journal of Advanced Manufacturing Technology, 113(11), 3613–3628.

Danish, M., Gupta, M. K., Rubaiee, S., Ahmed, A., Sarıkaya, M., & Krolczyk, G. M. (2022). Environmental, technological and economical aspects of cryogenic assisted hard machining operation of inconel 718: A step towards green manufacturing. Journal of Cleaner Production, 337, 130483.

Knight, W. A., & Boothroyd, G. (2005). Fundamentals of metal machining and machine tools. CRC Press.

Vipindas, K., & Mathew, J. (2019). Wear behavior of TiAlN coated WC tool during micro end milling of Ti–6Al–4V and analysis of surface roughness. Wear, 424–425, 165–182.

Çalışkan, H., & Küçükköse, M. (2015). The effect of aCN/TiAlN coating on tool wear, cutting force, surface finish and chip morphology in face milling of Ti6Al4V superalloy. International Journal of Refractory Metals and Hard Materials, 50, 304–312.

Hong, S. Y., Ding, Y., & Jeong, W. C. (2001). Friction and cutting forces in cryogenic machining of Ti–6Al–4V. International Journal of Machine Tools and Manufacture, 41(15), 2271–2285.

Gupta, M. K., Khan, A. M., Song, Q., Liu, Z., Khalid, Q. S., Jamil, M., et al. (2021). A review on conventional and advanced minimum quantity lubrication approaches on performance measures of grinding process. International Journal of Advanced Manufacturing Technology, 117(3), 729–750.

Şap, E., Usca, Ü. A., Gupta, M. K., Kuntoğlu, M., Sarıkaya, M., Pimenov, D. Y., et al. (2021). Parametric optimization for improving the machining process of Cu/Mo-SiCp composites produced by powder metallurgy. Materials, 14(8), 1921.

Mia, M., & Dhar, N. R. (2017). Optimization of surface roughness and cutting temperature in high-pressure coolant-assisted hard turning using Taguchi method. International Journal of Advanced Manufacturing Technology, 88(1), 739–753.

Sarıkaya, M., & Güllü, A. (2014). Taguchi design and response surface methodology based analysis of machining parameters in CNC turning under MQL. Journal of Cleaner Production, 65, 604–616.

Yıldırım, Ç. V., Kıvak, T., Sarıkaya, M., & Şirin, Ş. (2020). Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. Journal of Materials Research and Technology, 9(2), 2079–2092.

Ross, N. S., Manimaran, G., Anwar, S., Rahman, M. A., Erdi Korkmaz, M., Gupta, M. K., et al. (2021). Investigation of surface modification and tool wear on milling Nimonic 80A under hybrid lubrication. Tribology International, 155, 106762.

Khan, M. A., Jaffery, S. H. I., Khan, M., Younas, M., Butt, S. I., Ahmad, R., et al. (2020). Multi-objective optimization of turning titanium-based alloy Ti-6Al-4V under dry, wet, and cryogenic conditions using gray relational analysis (GRA). International Journal of Advanced Manufacturing Technology, 106(9), 3897–3911.

Sun, Y., Huang, B., Puleo, D. A., & Jawahir, I. S. (2015). Enhanced machinability of Ti-5553 alloy from cryogenic machining: Comparison with MQL and flood-cooled machining and modeling. Procedia CIRP, 31, 477–482.

Aramcharoen, A. (2016). Influence of cryogenic cooling on tool wear and chip formation in turning of titanium alloy. Procedia CIRP, 46, 83–86.

Danish, M., Gupta, M. K., Rubaiee, S., Ahmed, A., & Korkmaz, M. E. (2021). Influence of hybrid Cryo-MQL lubri-cooling strategy on the machining and tribological characteristics of Inconel 718. Tribology International, 163, 107178.

Liu, Y., Chen, H., Zhang, L., Wu, X., & Wang, X.-j. (2020). Energy consumption prediction and diagnosis of public buildings based on support vector machine learning: A case study in China. Journal of Cleaner Production, 272, 122542.

Airao, J., Nirala, C. K., Bertolini, R., Krolczyk, G. M., & Khanna, N. (2022). Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribology International, 169, 107494.

Kouam, J., Songmene, V., Balazinski, M., & Hendrick, P. (2015). Effects of minimum quantity lubricating (MQL) conditions on machining of 7075–T6 aluminum alloy. International Journal of Advanced Manufacturing Technology, 79(5), 1325–1334.

Bordin, A., Sartori, S., Bruschi, S., & Ghiotti, A. (2017). Experimental investigation on the feasibility of dry and cryogenic machining as sustainable strategies when turning Ti6Al4V produced by Additive Manufacturing. Journal of Cleaner Production, 142, 4142–4151.

Ambigai, R., & Prabhu, S. (2019). Fuzzy logic algorithm based optimization of the tribological behavior of Al–Gr–Si3N4 hybrid composite. Measurement, 146, 736–748.

Şap, E. (2021). Investigation of mechanical properties of Cu/Mo-SiCp composites produced with P/M, and their wear behaviour with the Taguchi method. Ceramics International, 47(18), 25910–25920.

Dwivedi, S. P., Saxena, A., Sharma, S., Singh, G., Singh, J., Mia, M., et al. (2021). Effect of ball-milling process parameters on mechanical properties of Al/Al2O3/collagen powder composite using statistical approach. Journal of Materials Research and Technology, 15, 2918–2932.

Mia, M., Dey, P. R., Hossain, M. S., Arafat, M. T., Asaduzzaman, M., Shoriat Ullah, M., et al. (2018). Taguchi S/N based optimization of machining parameters for surface roughness, tool wear and material removal rate in hard turning under MQL cutting condition. Measurement, 122, 380–391.

Funding

There was no financial assistance for the author(s)’ investigation, writing, or publishing of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) stated that they had no possible conflicts of interest in relation to the research, writing, and/or publishing of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Şap, S. Machining and Energy Aspect Assessment with Sustainable Cutting Fluid Strategies of Al–12Si Based Hybrid Composites. Int. J. of Precis. Eng. and Manuf.-Green Tech. 11, 33–53 (2024). https://doi.org/10.1007/s40684-023-00544-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-023-00544-1