Abstract

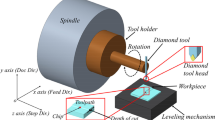

Free-form optics made of hard and brittle materials possesses the reflection and imaging functions that are difficult to be achieved by traditional optics and are widely used in various high energy space optical systems. However, free-form optics made of hard and brittle materials poses great challenges to ultra-precision machining due to its extreme demands of complex surface shapes with nonrotational asymmetric, submicron profile accuracy, controllable scallop height, nanometer surface roughness and ductile grinding surfaces. The freeform generation technique of the slow tool servo with diamond grinding wheel (STS-DGW) previously proposed by us was used to manufacture free-form optics made of hard and brittle materials. First, a theoretical model of scallop height during grinding of biconical free-form surface was established, and the effects of curvature changes on scallop height were studied. Subsequently, the profile error caused by the centering error of diamond wheel was calculated theoretically, and an accurate adjustment method of the grinding wheel position was proposed. Then, an undeformed chip thickness model for achieving ductile grinding was established, and the simulation calculation of critical grinding parameters was carried out. Ultimately, a typical off-axis biconical free-form optics with submicron profile accuracy, a controllable scallop height, nanometer surface roughness, and ductile grinding surfaces was successfully fabricated on single-crystal silicon using the proposed STS-DGW. Compared with the previous research, the profile accuracy was further improved, a controllable scallop height and ductile grinding surface was achieved.

Similar content being viewed by others

References

Fang, F. Z., Zhang, X. D., Weckenmann, A., Zhang, G. X., & Evans, C. (2013). Manufacturing and measurement of freeform optics. CIRP Annals-Manufacturing Technology, 62, 823–846. https://doi.org/10.1016/j.cirp.2013.05.003

Kong, L. B., & Cheung, C. F. (2011). Design, fabrication and measurement of ultra-precision micro-structured freeform surfaces. Computers & Industrial Engineering, 61, 216–225. https://doi.org/10.1016/j.cie.2011.03.014

Lang, A. L., Song, Z. J., He, C. Y., & Sang, Y. C. (2017). Profile error evaluation of free-form surface using sequential quadratic programming algorithm. Precision Engineering, 47, 344–352. https://doi.org/10.1016/j.precisioneng.2016.09.008

Rungasamy, A. E., Craig, K. J., & Meyer, J. P. (2021). A review of linear Fresnel primary optical design methodologies. Solar Energy, 224, 833–854. https://doi.org/10.1016/j.solener.2021.06.021

Lee, X. B., Wang, C. H., Luo, Z. X., & Li, S. Q. (2020). Optical design of a new folding scanning system in MEMS-based lidar. Optics & Laser Technology, 125, 106013. https://doi.org/10.1016/j.optlastec.2019.106013

Wang, J. H., Zhao, Q. L., Zhang, C. Y., Guo, B., & Yuan, J. L. (2021). Arc envelope grinding of sapphire steep aspheric surface with SiC-reinforced resin-bonded diamond wheel. International Journal of Precision Engineering and Manufacturing-Green Technology, 8, 1083–1094. https://doi.org/10.1007/s40684-020-00225-3

Zhang, S. J., To, S., Zhu, Z. W., & Zhang, G. Q. (2016). A review of fly cutting applied to surface generation in ultra-precision machining. International Journal of Machine Tools and Manufacture, 103, 13–27. https://doi.org/10.1016/j.ijmachtools.2016.01.001

Yi, B. W., Qiao, F., Huang, N. D., Wang, X. S., Wu, S. J., & Biermann, D. (2021). Adaptive sampling point planning for free-form surface inspection under multi-geometric constraints. Precision Engineering, 72, 95–101. https://doi.org/10.1016/j.precisioneng.2021.04.009

Liu, Y. H., Zhao, W. Z., Sun, R., & Yue, X. W. (2020). Optimal path planning for automated dimensional inspection of free-form surfaces. Journal of Manufacturing Systems, 56, 84–92. https://doi.org/10.1016/j.jmsy.2020.05.008

Lee, G., & Mou, J. (2000). Measurement error reduction in automated inspection of free-form surfaces defined by cubic B-Spline. Journal of Manufacturing Processes, 2, 174–186. https://doi.org/10.1016/S1526-6125(00)70119-8

Hauer, M., Jüttler, B., & Schicho, J. (2019). Projective and affine symmetries and equivalences of rational and polynomial surfaces. Journal of Computational and Applied Mathematics, 349, 424–437. https://doi.org/10.1016/j.cam.2018.06.026

Sohn, I. B., Choi, H. K., Noh, Y. C., Kim, J., & Ahsan, M. S. (2019). Laser assisted fabrication of micro-lens array and characterization of their beam shaping property. Applied Surface Science, 479, 375–385. https://doi.org/10.1016/j.apsusc.2019.02.083

Zhang, X. Q., Huang, R., Liu, K., Kumar, A. S., & Shan, X. C. (2018). Rotating-tool diamond turning of Fresnel lenses on a roller mold for manufacturing of functional optical film. Precision Engineering, 51, 445–457. https://doi.org/10.1016/j.precisioneng.2017.09.016

Masood, A., Siddiqui, R., Pinto, M., Rehman, H., & Khan, M. A. (2015). Tool path generation, for complex surface machining, using point cloud data. Procedia CIRP, 26, 397–402. https://doi.org/10.1016/j.procir.2014.07.076

Zhu, D. Y., Chen, Y., Hu, Z. J., Li, L. S., & Zhang, Y. F. (2021). Experimental study on measurement of free-form surface with wavefront reconstruction algorithm. Infrared Physics & Technology, 115, 103671. https://doi.org/10.1016/j.infrared.2021.103671

Mali, R. A., Gupta, T. V. K., & Ramkumar, J. (2021). A comprehensive review of free-form surface milling—Advances over a decade. Journal of Manufacturing Processes, 62, 132–167. https://doi.org/10.1016/j.jmapro.2020.12.014

Hu, Y., Xu, M. X., Xu, X. Z., Yang, Z. J., & Zhang, Y. L. (2014). An accurate interpolator for FTS diamond turning of optical free-form surface. The International Journal of Advanced Manufacturing Technology, 73, 635–638. https://doi.org/10.1007/s00170-014-5856-x

Brinksmeier, E., Riemer, O., & Osmer, J. (2008). Tool path generation for ultra-precision machining of free-form surfaces. Production Engineering - Research and Development, 2, 241–246. https://doi.org/10.1007/s11740-008-0086-4

Sun, Z. W., To, S., & Zhang, S. J. (2018). A novel ductile machining model of single-crystal silicon for freeform surfaces with large azimuthal height variation by ultra-precision fly cutting. International Journal of Machine Tools and Manufacture, 135, 1–11. https://doi.org/10.1016/j.ijmachtools.2018.07.005

Shi, Z. Q., Zhao, Q. L., Guo, B., Ji, T. Y., & Wang, H. (2020). A review on processing polycrystalline magnesium aluminate spinel (MgAl2O4): Sintering techniques, material properties and machinability. Materials & Design, 193, 108858. https://doi.org/10.1016/j.matdes.2020.108858

Wang, S., Zhao, Q. L., Guo, B., & Pan, Y. C. (2020). Ultra-precision raster grinding of monocrystalline silicon biconical free-form optics using arc-shaped diamond grinding wheels. Journal of Manufacturing Processes, 58, 1064–1074. https://doi.org/10.1016/j.jmapro.2020.09.020

Wang, S., Zhao, Q. L., Pan, Y. C., & Guo, B. (2021). Ultra-precision raster grinding biconical optics with a novel profile error compensation technique based on on-machine measurement and wavelet decomposition. Journal of Manufacturing Processes, 67, 128–140. https://doi.org/10.1016/j.jmapro.2021.04.059

Wang, S., Zhang, Q., Zhao, Q. L., & Guo, B. (2021). Surface generation and materials removal mechanism in ultra-precision grinding of biconical optics based on slow tool servo with diamond grinding wheels. Journal of Manufacturing Processes, 72, 1–14. https://doi.org/10.1016/j.jmapro.2021.10.010

Kong, L. B., Cheung, C. F., & Lee, W. B. (2016). A theoretical and experimental investigation of orthogonal slow tool servo machining of wavy microstructured patterns on precision rollers. Precision Engineering, 43, 315–327. https://doi.org/10.1016/j.precisioneng.2015.08.012

Zhu, Z. W., To, S., Zhu, W. L., Huang, P., & Zhou, X. Q. (2019). Cutting forces in fast-/slow tool servo diamond turning of micro-structured surfaces. International Journal of Machine Tools and Manufacture, 136, 62–75. https://doi.org/10.1016/j.ijmachtools.2018.09.003

Huang, P., Wu, X. Y., To, S., Zhu, L. M., & Zhu, Z. W. (2020). Deterioration of form accuracy induced by servo dynamics errors and real-time compensation for slow tool servo diamond turning of complex-shaped optics. International Journal of Machine Tools and Manufacture, 154, 103556. https://doi.org/10.1016/j.ijmachtools.2020.103556

Nagayama, K., & Yan, J. W. (2021). Deterministic error compensation for slow tool servo-driven diamond turning of freeform surface with nanometric form accuracy. Journal of Manufacturing Processes, 64, 45–57. https://doi.org/10.1016/j.jmapro.2021.01.015

Mishra, V., Kumar, N., Sharma, R., Garg, H., & Karara, V. (2020). Development of aspheric lenslet array by slow tool servo machining. Materials Today: Proceedings, 24, 1602–1607. https://doi.org/10.1016/j.matpr.2020.04.481

Mukaida, M., & Yan, J. W. (2017). Ductile machining of single-crystal silicon for microlens arrays by ultraprecision diamond turning using a slow tool servo. International Journal of Machine Tools and Manufacture, 115, 2–14. https://doi.org/10.1016/j.ijmachtools.2016.11.004

Yin, Y. Q., Dai, Y. F., Li, S. Y., Guan, C. L., & Tie, G. P. (2011). Fabrication of off-axis aspheric surfaces using a slow tool servo. International Journal of Machine Tools and Manufacture, 51, 404–410. https://doi.org/10.1016/j.ijmachtools.2011.01.008

Yan, G. P., & Fang, F. Z. (2019). Fabrication of optical freeform molds using slow tool servo with wheel normal grinding. CIRP Annals-Manufacturing Technology, 68, 341–344. https://doi.org/10.1016/j.cirp.2019.04.083

Mishra, V., Burada, D. R., Pant, K. K., Karar, V., Jha, S., & Khan, G. S. (2019). Form error compensation in the slow tool servo machining of freeform optics. The International Journal of Advanced Manufacturing Technology, 105, 1623–1635. https://doi.org/10.1007/s00170-019-04359-w

Ning, P. X., Zhao, J., Ji, S. J., Li, J. J., & Dai, H. D. (2020). Ultra-precision machining of a large amplitude umbrella surface based on slow tool servo. International Journal of Precision Engineering and Manufacturing, 21, 1999–2010. https://doi.org/10.1007/s12541-020-00401-0

Wang, S. L., Lin, B., Zhang, X. F., Liang, J. M., & Wang, Y. (2014). A novel tool path generation algorithm for plane envelope grinding convex surface based on constant scallop height method. The International Journal of Advanced Manufacturing Technology, 78, 1087–1099. https://doi.org/10.1007/s00170-014-6668-8

Shchurov, I. A., & Al-Taie, L. H. (2017). Constant scallop-height tool path generation for ball-end mill cutters and three-axis CNC milling machines. Procedia Engineering, 206, 1137–1141. https://doi.org/10.1016/j.proeng.2017.10.607

Feng, H. Y., & Li, H. W. (2002). Constant scallop-height tool path generation for three-axis sculptured surface machining. Computer-Aided Design, 34, 647–654. https://doi.org/10.1016/S0010-4485(01)00136-1

Zhang, X. F., Xie, J., Xie, H. F., & Li, L. H. (2012). Experimental investigation on various tool path strategies influencing surface quality and form accuracy of CNC milled complex freeform surface. The International Journal of Advanced Manufacturing Technology, 59, 647–654. https://doi.org/10.1007/s00170-011-3515-z

Chen, B., Li, S. C., Deng, Z. H., Guo, B., & Zhao, Q. L. (2017). Grinding marks on ultra-precision grinding spherical and aspheric surfaces. International Journal of Precision Engineering and Manufacturing-Green Technology, 4, 419–429. https://doi.org/10.1007/s40684-017-0047-5

Chen, S. S., Cheung, C. F., Zhang, F. H., & Liu, M. Y. (2019). Optimization of tool path for uniform scallop-height in ultra-precision grinding of free-form surfaces. Nanomanufacturing and Metrology, 2, 215–224. https://doi.org/10.1007/s41871-019-00048-0

Jia, Z. Y., Zhao, X. X., Ma, J. W., Chen, S. Y., Qin, F. Z., & Liu, Z. (2019). Toolpath generation in sub-regional processing with constraint of constant scallop-height at boundary for complex curved surface. Precision Engineering, 55, 217–230. https://doi.org/10.1016/j.precisioneng.2018.09.009

Lee, W. B., Cheung, C. F., Chiu, W. M., & Leung, T. P. (2000). An investigation of residual form error compensation in the ultra-precision machining of aspheric surfaces. Journal of Materials Processing Technology, 99, 129–134. https://doi.org/10.1016/S0924-0136(99)00403-3

Blackley, W. S., & Scattergood, R. O. (1991). Ductile-regime machining model for diamond turning of brittle materials. Precision Engineering, 13, 95–103. https://doi.org/10.1016/0141-6359(91)90500-I

Bifano, T. G., Dow, T. A., & Scattergood, R. O. (1992). Ductile-regime grinding: A new technology for machining brittle materials. Precision Engineering, 14, 54. https://doi.org/10.1016/0141-6359(92)90161-O

Yu, D. P., Wong, Y. S., & Hong, G. S. (2011). Ultraprecision machining of micro-structured functional surfaces on brittle materials. Journal of Micromechanics and Microengineering, 21, 095011. https://doi.org/10.1088/0960-1317/21/9/095011

Zhang, C. Y., Liu, H., Zhao, Q. L., Guo, B., Wang, J. H., & Zhang, J. (2020). Mechanisms of ductile mode machining for AlON ceramics. Ceramics International, 46, 1844–1853. https://doi.org/10.1016/j.ceramint.2019.09.161

Zhang, Q. L., Fu, Y. C., Su, H. H., Zhao, Q. L., & To, S. (2018). Surface damage mechanism of monocrystalline silicon during single point diamond grinding. Wear, 396–397, 48–55. https://doi.org/10.1016/j.wear.2017.11.008

Guo, J. J., Wang, K., Fujita, T., McCauley, J. W., Singh, J. P., & Chen, M. W. (2011). Nanoindentation characterization of deformation and failure of aluminum oxynitride. Acta Materialia, 59, 1671–1679. https://doi.org/10.1016/j.actamat.2010.11.034

Zhang, C. Y., Guo, B., Zhao, Q. L., Liu, H., Wang, J. H., & Zhang, J. (2019). Ultra-precision grinding of AlON ceramics: Surface finish and mechanisms. Journal of the European Ceramic Society, 39, 3668–3676. https://doi.org/10.1016/j.jeurceramsoc.2019.05.005

Blake, P. N., & Scattergood, R. O. (1990). Ductile-regime machining of germanium and silicon. Journal of the American Ceramic Society, 73, 949–957. https://doi.org/10.1111/j.1151-2916.1990.tb05142.x

Lankford, J., & Davidson, D. L. (1979). The crack-initiation threshold in ceramic materials subject to elastic/plastic indentation. Journal of Materials Science, 14, 1662–1668. https://doi.org/10.1007/BF00569288

Li, H. N., Yu, T. B., Zhu, L. D., & Wang, W. S. (2017). Analytical modeling of ground surface topography in monocrystalline silicon grinding considering the ductile-regime effect. Archives of Civil and Mechanical Engineering, 17, 880–893. https://doi.org/10.1016/j.acme.2017.03.010

Acknowledgements

This work was supported by the National Key Research and Development Program of China [2018YFA0703400].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Zhao, Q. & Guo, B. Ultra-precision Ductile Grinding of Off-Axis Biconical Free-Form Optics with a Controllable Scallop Height Based on Slow Tool Servo with Diamond Grinding Wheels. Int. J. of Precis. Eng. and Manuf.-Green Tech. 10, 1169–1188 (2023). https://doi.org/10.1007/s40684-022-00481-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-022-00481-5