Abstract

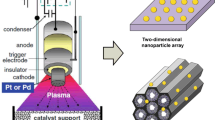

A novel rotary-type atomic layer deposition (ALD) process for coating platinum thin film on three-dimensional (3D) substrates is demonstrated. High uniformity and conformability of the platinum thin-film deposition on 3D substrates were confirmed, ensuring the controllability of the new ALD technique. The results for this technique surpassed those of the conventional wet method and ordinary atomic layer deposition, which both have a limited specific surface area. To demonstrate the application of this new technology, Pt nano-film coated γ-Al2O3 was produced using the rotary-type ALD and applied to diesel oxidation catalysts (DOCs). The produced DOCs showed high Pt content when the number of ALD cycles was increased, and thereby exhibited more complete combustion of gaseous pollutants, such as CO, C3H8, and NO, even at lower temperatures. Pt nano-film deposition by the rotary-type ALD process was first optimised on Si wafer substrates. The process was controlled by four parameters: processing temperature, number of ALD cycles, precursor pulse time, and reactant pulse time. Deposition of the Pt nano-film was mainly determined by the processing temperature and the number of ALD cycles. The average growth per cycle and density of the Pt nano-film were found to be 0.8 Å/cycle and 21.0 g/cm3, respectively. The same procedure and conditions were applied to 3D γ-Al2O3 powder substrates for DOCs, which demonstrated greater conversion performance compared with conventional Pt-used DOCs.

Similar content being viewed by others

Data Availability

Not applicable.

References

Eric, D., Wachsman, D., & Lee, K. T. (2011). Lowering the temperature of solid oxide fuel cells. Science, 334, 935–939. https://doi.org/10.1126/science.1204090

Yuyan Shao, J., Liu, Y., Wang, A., & Lin, Y. (2009). Novel catalyst support materials for PEM fuel cells: current status and future prospects. Journal of Materials Chemistry, 19(1), 46–59. https://doi.org/10.1039/B808370C

Yunhui Gong, D., Palacio, X., Song, R. L., Patel, X., Liang, X., Zhao, J. B., & Goodenough, H. K. (2013). Stabilizing nanostructured solid oxide fuel cell cathode with atomic layer deposition. Nano Letters, 13(9), 4340–4345. https://doi.org/10.1021/nl402138w

Brahim, C., Ringuedé, A., Cassir, M., Putkonen, M., & Niinistö, L. (2007). Electrical properties of thin yttria-stabilized zirconia overlayers produced by atomic layer deposition for solid oxide fuel cell applications. Applied Surface Science, 253.8, 3962–3968. https://doi.org/10.1016/j.apsusc.2006.08.043

Sambhaji, M., Pawar, J., Kim, A. I., Inamdar, H., Woo, Y., Jo, B. S., Pawar, S., Cho, H., & Kim, I. M. (2016). Multi-functional reactively-sputtered copper oxide electrodes for supercapacitor and electro-catalyst in direct methanol fuel cell applications. Scientific Reports, 6, 1–9. https://doi.org/10.1038/srep21310

Anthony, S., Yu, R., Küngas, J. M., Vohs, & Gorte, R. J. (2013). Modification of SOFC cathodes by atomic layer deposition. Journal of the Electrochemical Society, 160, F1225. https://doi.org/10.1149/2.045311jes

Seunghyeon Kye, H. J., Kim, D., Go, B. C., Yang, J. W., Shin, S., Lee, & An, J. (2021). Ultralow-loading ruthenium catalysts by plasma-enhanced atomic layer deposition for a solid oxide fuel cell. ACS Catalysis, 11(6), 3523–3529. https://doi.org/10.1021/acscatal.0c04526

Kim, H. J., Kil, M. J., Lee, J., Yang, B. C., Go, D., Lim, Y., Kim, Y. B., & An, J. (2021). Ru/Samaria-doped ceria gradient cermet anode for direct-methane solid oxide fuel cell. Applied Surface Science, 538, 148105. https://doi.org/10.1016/j.apsusc.2020.148105

Sofiane Boukhalfa, K., Evanoff, & Yushin, G. (2012). Atomic layer deposition of vanadium oxide on carbon nanotubes for high-power supercapacitor electrodes. Energy & Environmental Science, 5, 6872–6879. https://doi.org/10.1039/c2ee21110f

Cao Guan, X., Qian, X., Wang, Y., Cao, Q., Zhang, A., Li, A., & Wang, J. (2015). Atomic layer deposition of Co3O4 on carbon nanotubes/carbon cloth for high-capacitance and ultrastable supercapacitor electrode. Nanotechnology, 26(9), 094001. https://doi.org/10.1088/0957-4484/26/9/094001

Xiangbo Meng, X. Q., Yang, S., & Sun, X. (2012). Emerging applications of atomic layer deposition for lithium-ion battery studies. Advanced Materials, 24, 3589–3615. https://doi.org/10.1002/adma.201200397

Jung, Y. S., Cavanagh, A. S., Riley, L. A., Kang, S. H., Dillon, A. C., & Groner, M. D. (2010). Ultrathin direct atomic layer deposition on composite electrodes for highly durable and safe Li-ion batteries. Advanced Materials, 22, 2172–2176. https://doi.org/10.1002/adma.200903951

Zhao, M. Q., Liu, X. F., Zhang, Q., Tian, G. L., Huang, J. Q., Zhu, W., & Wei, F. (2012). Graphene/single-walled carbon nanotube hybrids: one-step catalytic growth and applications for high-rate Li–S batteries. ACS Nano, 6, 10759–10769. https://doi.org/10.1021/nn304037d

Fernando Dorado, A., de Lucas-Consuegra, P., & Vernoux, J. L. (2007). Electrochemical promotion of platinum impregnated catalyst for the selective catalytic reduction of NO by propene in presence of oxygen. Applied Catalysis B: Environmental, 73, 242–50. https://doi.org/10.1016/j.apcatb.2006.12.001

Javier, G. M., Susana, Q.-D., Noelia, G.-H., & Avelina, G.-G. (2017). Catalyzed particulate filter regeneration by platinum versus noble metal-free catalysts: from principles to real application. Topics in Catalysis, 60(1), 2–12. https://doi.org/10.1007/s11244-016-0730-8

Qiuhong Zhou, K., Zhong, W., Fu, Q., Huang, Z., Wang, & Nie, B. (2015). Nanostructured platinum catalyst coating on diesel particulate filter with a low-cost electroless deposition approach. Chemical Engineering Journal, 270, 320–326. https://doi.org/10.1016/j.cej.2015.01.131

Tseng, C. H., Chang, S. M., Hu, S. C., Chen, Y. C., Shiue, A., Li, Z., Huang, P. H., & Leggett, G. (2021). Platinum-supported aluminum oxide on activated carbon filter media for removal of formaldehyde in the indoor condition. International Journal of Environmental Science and Technology, 18(12), 3747–3760. https://doi.org/10.1007/s13762-021-03130-7

Cuiting Yang, G., Miao, Y., Pi, Q., Xia, J., Wu, Z., Li, & Xia, J. (2019). Abatement of various types of VOCs by adsorption/catalytic oxidation: A review. Chemical Engineering Journal, 370, 1128–1153. https://doi.org/10.1016/j.cej.2019.03.232

Neil, P., Dasgupta, X., Meng, J. W., & Elam, A. B. (2015). Atomic layer deposition of metal sulfide materials. Accounts of Chemical Research, 48, 2341–348. https://doi.org/10.1021/ar500360d

Guizhen Wang, Z., Gao, S., Tang, C., Chen, F., Duan, S., Zhao, S., Lin, Y., Feng, L., & Zhou, & Qin, Y. (2012). Microwave absorption properties of carbon nanocoils coated with highly controlled magnetic materials by atomic layer deposition. ACS Nano, 6, 11009–11017. https://doi.org/10.1021/nn304630h

Han, J. H., Chung, Y. J., Park, B. K., Kim, S. K., Kim, H. S., Kim, C. G., & Chung, T. M. (2014). Growth of p-type tin (II) monoxide thin films by atomic layer deposition from bis (1-dimethylamino-2-methyl-2propoxy) tin and H2O. Chemistry of Materials, 26, 6088–6091. https://doi.org/10.1021/cm503112v

Peng, Q., Sun, X. Y., Spagnola, J. C., Kevin Hyde, G., Spontak, R. J., & Parsons, G. N. (2007). Atomic layer deposition on electrospun polymer fibers as a direct route to Al2O3 microtubes with precise wall thickness control. Nano Letters, 7(3), 719–722. https://doi.org/10.1021/nl062948i

Tae, H., Cho, N., Farjam, C. R., Allemang, C. P., Pannier, E., Kazyak, C., Huber, M., Rose, O., Trejo, R. L., Peterson, K., & Barton, N. P. (2020). Area-selective atomic layer deposition patterned by electrohydrodynamic jet printing for additive manufacturing of functional materials and devices. ACS Nano, 14, 17262–17272. https://doi.org/10.1021/acsnano.0c07297

Mari Napari, T. N., Huq, D. J., Meeth, M. J., Heikkilä, K. M., Niang, H., Wang, T., Iivonen, H., Wang, M., Leskelä, M., Ritala, A. J., Flewitt, R. L. Z., & Hoye, R. R. (2021). Role of ALD Al2O3 surface passivation on the performance of p-type Cu2O thin film transistors. ACS Applied Materials & Interfaces, 13(3), 4156–4164. https://doi.org/10.1021/acsami.0c18915

Akbari, M. K., Hai, Z., Wei, Z., Detavernier, C., Solano, E., Verpoort, F., & Zhuiykov, S. (2018). ALD-developed plasmonic two-dimensional Au–WO3–TiO2 heterojunction architectonics for design of photovoltaic devices. ACS Applied Materials & Interfaces, 10, 10304–10314. https://doi.org/10.1021/acsami.7b17508

Xicheng Wang, Z., Bao, Y. C., Chang, & Liu, R. S. (2020). Perovskite quantum dots for application in high color gamut backlighting display of light-emitting diodes. ACS Energy Letters, 5, 3374–3396. https://doi.org/10.1021/acsenergylett.0c01860

Chen, F., Yang, H., Li, K., Deng, B., Li, Q., Liu, X., Dong, B., Wang, X. X. D., Qin, Y., Wang, S. M., Zhang, K. Q., & Xu, W. (2017). Facile and effective coloration of dye-inert carbon fiber fabrics with tunable colors and excellent laundering durability. Acs Nano, 11, 10330–10336. https://doi.org/10.1021/acsnano.7b05139

Jiazhen Sheng, T. H., Kang, H. D. H., Yi, Y., Lim, J. H., & Park, J. S. (2019). Design of InZnSnO semiconductor alloys synthesized by supercycle atomic layer deposition and their rollable applications. ACS Applied Materials & Interfaces, 11, 12683–12692. https://doi.org/10.1021/acsami.9b02999

Sarli, V. D., Landi, G., Lisi, L., Saliva, A., & Benedetto, A. D. (2016). Catalytic diesel particulate filters with highly dispersed ceria: Effect of the soot-catalyst contact on the regeneration performance. Applied Catalysis B: Environmental, 197, 116–124. https://doi.org/10.1016/j.apcatb.2016.01.073

Wooseok Kang, B., Choi, & Kim, H. (2013). Characteristics of the simultaneous removal of PM and NOx using CuNb-ZSM-5 coated on diesel particulate filter. Journal of Industrial and Engineering Chemistry, 19, 1406–1412. https://doi.org/10.1016/j.jiec.2013.01.004

Zhang, Y., Lou, D., Tan, P., Zhi-yuan, & Hu (2020). Study of spatial and temporal aging characteristic of catalyzed diesel particulate filter catalytic performance used for diesel vehicle. Scientific Reports, 10.1, 1–13. https://doi.org/10.1038/s41598-020-76634-w

Titta Aaltonen, M., Ritala, T., Sajavaara, J., Keinonen, Markku, & Leskelä. (2003). Atomic layer deposition of platinum thin films. Chemistry of Materials, 15(9), 1924–1928. https://doi.org/10.1021/cm021333t

Clinton Lien, M., Konh, B., Chen, A. V., Teplyakov, & Zaera, F. (2018). Gas-phase electron-impact activation of atomic layer deposition (ALD) precursors: MeCpPtMe3. The Journal of Physical Chemistry Letters, 9.16, 4602–4606. https://doi.org/10.1021/acs.jpclett.8b02125

Sahu, N. K., Prakash, A., & Bahadur, D. (2014). Role of different platinum precursors on the formation and reaction mechanism of FePt nanoparticles and their electrocatalytic performance towards methanol oxidation. Dalton Transactions, 43, 4892–4900. https://doi.org/10.1039/C3DT53147C

Worajit Setthapun, W. D., Williams, S. M., Kim, H., Feng, J. W., Elam, A., Rabuffetti, K. R., Poeppelmeier, P. C., Stair, E. A., Stach, Fabio, H., Ribeiro, J. T., Miller, & Marshall, C. L. (2010). Genesis and evolution of surface species during Pt atomic layer deposition on oxide supports characterized by in situ XAFS analysis and water-gas shift reaction. The Journal of Physical Chemistry C, 114(21), 9758–9771. https://doi.org/10.1021/jp911178m

Lien, C., Sun, H., Qin, X., & Zaera, F. (2018). Platinum atomic layer deposition on metal substrates: A surface chemistry study. Surface Science, 677, 161–166. https://doi.org/10.1016/j.susc.2018.07.002

Sharma, H., & Mhadeshwar, A. (2012). A detailed microkinetic model for diesel engine emissions oxidation on platinum based diesel oxidation catalysts (DOC). Applied Catalysis B: Environmental, 127, 190–204. https://doi.org/10.1016/j.apcatb.2012.08.021

Hauff, K., Dubbe, H., Tuttlies, U., Eigenberger, G., & Nieken, U. (2013). Platinum oxide formation and reduction during NO oxidation on a diesel oxidation catalyst-macrokinetic simulation. Applied Catalysis B: Environmental, 129, 273–281. https://doi.org/10.1016/j.apcatb.2012.09.022

Tang, W., Lu, X., Liu, F., Du, S., Weng, J., Hoang, S., Wang, S., Nam, C. Y., & Gao, P. X. (2019). Ceria-based nanoflake arrays integrated on 3D cordierite honeycombs for efficient low-temperature diesel oxidation catalyst. Applied Catalysis B: Environmental, 245, 623–634. https://doi.org/10.1016/j.apcatb.2019.01.028

Salomons, S., Votsmeier, M., Hayes, R. E., Drochner, A., Vogel, H., & Giesho, J. (2006). CO and H2 oxidation on a platinum monolith diesel oxidation catalyst. Catalysis Today, 117, 491–497. https://doi.org/10.1016/j.cattod.2006.06.001

Son Hoang, X., Lu, W., Tang, S., Wang, S., Du, C. Y., Nam, Y., Ding, R. D., & VinluanIII (2019). Jie Zheng, and Pu-Xian Gao, High performance diesel oxidation catalysts using ultra-low Pt loading on titania nanowire array integrated cordierite honeycombs. Catalysis Today, 320, 2–10. https://doi.org/10.1016/j.cattod.2017.11.019

Shoynkhorova, T. B., Rogozhnikov, V. N., Ruban, N. V., Shilov, V. A., Potemkin, D. I., Simonov, P. A., Belyaev, V. D., Snytnikov, P. V., & Sobyanin, V. A. (2019). Composite Rh/Zr0.25Ce0.75O2–δ-ƞ-Al2O3/Fecralloy wire mesh honeycomb module for natural gas, LPG and diesel catalytic conversion to syngas. International Journal of Hydrogen Energy, 44, 9941–9948. https://doi.org/10.1016/j.ijhydene.2018.12.148

Ho, P. H., Woo, J., Ilmasani, R. F., Salam, M. A., Creaser, D., & Olsson, L. (2021). The effect of Si/Al ratio on the oxidation and sulfur resistance of beta zeolite-supported Pt and Pd as diesel oxidation catalysts. ACS Engineering Au. https://doi.org/10.1021/acsengineeringau.1c00016

Verena Pramhaas, M., Roiaz, N., Bosio, M., Corva, C., Rameshan, E., & Vesselli, H. (2020). Interplay between CO disproportionation and oxidation: on the origin of the CO reaction onset on atomic layer deposition-grown Pt/ZrO2 model catalysts. ACS Catalysis, 11, 1208–1214. https://doi.org/10.1021/acscatal.0c03974

Xie, S., Choi, S. I., Lu, N., Roling, L. T., Herron, J. A., Zhang, L., Park, J., Wang, J., Kim, M. J., & Xie, Z. (2014). Atomic layer-by-layer deposition of Pt on Pd nanocubes for catalysts with enhanced activity and durability toward oxygen reduction. Nano Letters, 14, 570–3576. https://doi.org/10.1021/nl501205j

Jason, R., Avila, E. J., De Marco, J. D., Emery, O. K., Farha, M. J., Pellin, J. T., Hupp, A., & Martinson, B. F. (2014). Real-time observation of atomic layer deposition inhibition: Metal oxide growth on self-assembled alkanethiols. ACS Applied Materials & Interfaces, 6, 11891–11898. https://doi.org/10.1021/am503008j

Matthieu, J., Weber, Adriaan, & J. M., Mackus, M. A., Verheijen, Cees, van der Marel, Wilhelmus, M. M., & Kessels,. (2012). Supported core/shell bimetallic nanoparticles synthesis by atomic layer deposition. Chemistry of Materials, 24(15), 2973–2977. https://doi.org/10.1021/cm301206e

Cooper, J., & Beecham, J. (2013). A study of platinum group metals in three-way autocatalysts. Platinum Metals Review, 57, 281–288. https://doi.org/10.1595/147106713X671457

Ata, R., Salman, C., Enger, X., Auvray, R., Lødeng, M., Menon, D., & Waller, & Rønning, M. (2018). Catalytic oxidation of NO to NO2 for nitric acid production over a Pt/Al2O3 catalyst. Applied Catalysis A General, 564, 142–146. https://doi.org/10.1016/j.apcata.2018.07.019

Acknowledgements

This work’s characterisation is supported by Research Institute of Advanced Materials (RIAM) at Seoul National University (SNU).

Funding

This work was supported by Material Innovation Leading Project through the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (2020M3H4A3081879). This work was supported by Tech-Bridge commercialization technology development project through Korea Technology and Information Promotion Agency (TIPA) funded by the ministry of SMEs (S3177448). This work was supported by the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (MSIT) of the Korean government (NRF-2021R1C1C1009200).

Author information

Authors and Affiliations

Contributions

SHY, MJK and HK conceived the idea. IJ and HMK supervised the project. HMK analysed Pt-coated Al2O3 powder by using transmission electron microscope. SGK and JH analysed Pt-coated Si wafer by x-ray reflectivity. ESL and YA tested Pt-coated DOC. SHY, MJK, JHJ and IJ wrote the manuscript. JWC, JA, JBC and IJ revised the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yoon, SH., Kil, M.J., Jeon, JH. et al. Conformal Three-Dimensional Platinum Coating Using Rotary-Type Atomic Layer Deposition for a Diesel Oxidation Catalyst Application. Int. J. of Precis. Eng. and Manuf.-Green Tech. 10, 1249–1261 (2023). https://doi.org/10.1007/s40684-022-00475-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-022-00475-3