Abstract

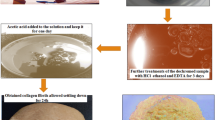

Nowadays, there is a lot of environmental pollution due to the wastes generated by the industries. In particular, the waste generated by leather industries produces more environmental pollution. Chrome containing leather waste (CCLW) also causes a lot of environmental pollution. In this study, an attempt has been made to use CCLW as reinforcement with aluminium. Collagen powder was extracted from CCLW. Extracted collagen powder was used to develop aluminium based composite after ball-milling with alumina particles. The parameters of the friction stir process (FSP) are optimized by the Box-Behnken Design. The optimum combination of FSP parameters was found to be the number of tool pass of 1, tool rotational speed of 965.20 rpm and transverse speed of 23.69 mm/min. Tensile strength and hardness were found to be 162.89 MPa and 53.24 BHN, respectively at an optimum combination of FSP parameters. Uniform distribution of reinforcement particles has been also observed for the composite developed at an optimum combination of FSP parameters. Results showed that tensile strength and hardness of composite were enhanced by about 20.65 % and 23.81 % respectively with respect to the base material.

Similar content being viewed by others

References

Kumar, S., Dwivedi, S. P., & Dwivedi, V. K. (2020). Synthesis and characterization of ball-milled eggshell and Al2O3 reinforced hybrid green composite material. Journal of Metals, Materials and Minerals, 30, 67–75

Dwivedi, S. P., Srivastava, A. K., Maurya, N. K., & Sahu, R. (2020). Microstructure and mechanical behaviour of Al/SiC/agro-waste RHA hybrid metal matrix composite. Revue des Composites et des Matériaux Avancés, 30, 43–47

Dwivedi, S. P., Sharma, P., & Saxena, A. (2020). Utilization of waste spent alumina catalyst and agro-waste rice husk ash as reinforcement materials with scrap aluminium alloy wheel matrix. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering. https://doi.org/10.1177/0954408920930634

Dwivedi, S. P., Dixit, A., & Bajaj, R. (2019). Development of bio-composite material by utilizing chrome containing leather waste with Al2O3 ceramic particles. Materials Research Express, 6, 105105

Mandal, A., Farhan, M. K., & Sastry, T. P. (2016). Effect of reinforced Al2O3 nanoparticles on collagen nanobiocomposite from chrome-containing leather waste for biomedical applications. Clean Technologies and Environmental Policy, 18, 765–773

Dwivedi, S. P. (2020). Effect of ball-milled MgO and Si3N4 addition on the physical, mechanical and thermal behaviour of aluminium based composite developed by hybrid casting technique. International Journal of Cast Metals Research, 33, 35–49

Dwivedi, S. P., Mishra, V. R., & Physico-Chemical. (2019). Mechanical and thermal behaviour of agro-waste RHA-reinforced green emerging composite material. Arabian Journal for Science and Engineering, 44, 8129–8142

Dwivedi, S. P., & Srivastava, A. K. (2020). Utilization of chrome containing leather waste in development of aluminium based green composite material. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 781–790

Dwivedi, S. P., & Saxena, A. (2020). Extraction of collagen powder from chrome containing leather waste and its composites with alumina employing different casting techniques. Materials Chemistry and Physics, 253, 123274

Agrawal, R. (2007). Ultrasonic backscattering in tissue: characterization through Nakagami-generalized inverse Gaussian distribution. Computers in Biology and Medicine, 37, 166–172

Singh, C. V., Pachauri, P., Dwivedi, S. P., Sharma, S., & Singari, R. M. (2019). Formation of functionally graded hybrid composite materials with Al2O3 and RHA reinforcements using friction stir process. Australian Journal of Mechanical Engineering. https://doi.org/10.1080/14484846.2019.1679583

Yang, K., Li, W. Y., Niu, P. L., Yang, X. W., & Xu, Y. X. (2018). Cold sprayed AA2024/Al2O3 metal matrix composites improved by friction stir processing: Microstructure characterization, mechanical performance and strengthening mechanisms. Journal of Alloys and Compounds, 736, 115–123

Fernandez, J. B., Macias, E. J., Muro, J., Caputi, L. S., Miriello, D., De Luca, R., Roca, A. S., & Fals, H. D. C. (2018). Tribological behavior of AA1050H24-graphene nanocomposite obtained by friction stir processing. Metals, 8, 113

Yang, R., Zhang, Z. Y., Zhao, Y. T., Chen, G., Guo, Y. H., Liu, M. P., & Zhang, J. (2015). Effect of multi-pass friction stir processing on microstructure and mechanical properties of Al3Ti/A356 composites. Materials Characterization, 106, 62–69

Khodabakhshi, F., Gerlich, A. P., Simchi, A., & Kokabi, A. H. (2015). Cryogenic friction-stir processing of ultrafine-grained Al-Mg-TiO2 nanocomposites. Materials Science & Engineering A: Structural Materials: Properties, Microstructure and Processing, 620, 471–482

Reddy, G. M., Rao, A. S., & Rao, K. S. (2013). Friction stir surfacing route: effective strategy for the enhancement of wear resistance of titanium alloy. Transactions of the Indian Institute of Metals, 66, 231–238

Hussain, G., Hashemi, R., Hashemi, H., & Al-ghamdi, K. A. (2016). An experimental study on multi-pass friction stir processing of Al/TiN composite: some microstructural, mechanical, and wear characteristics. The International Journal of Advanced Manufacturing Technology, 84, 533–546

Jerome, S., Govind, B. S., Kumaresh, B. S. P., & Ravisankar, B. (2012). Influence of microstructure and experimental parameters on mechanical and wear properties of Al-TiC surface composite by FSP route. Journal of Minerals and Materials Characterization and Engineering, 11(5), 493–507

Heydarian, A., Dehghani, K., & Slamkish, T. (2014). Optimizing powder distribution in production of surface nano-composite via friction stir processing. Metallurgical and Materials Transactions B, 45, 821–826

Silva, A. F., Marins, F. A. S., Dias, E. X., & Oliveira, J. B. S. (2019). Modeling the uncertainty in response surface methodology through optimization and Monte Carlo simulation: an application in stamping process. Materials & Design, 173, 107776

Sun, Y., He, D., Xue, F., & La, R. (2018). Effect of Tool Rotational Speeds on the Microstructure and Mechanical Properties of a Dissimilar Friction-Stir-Welded CuCrZr/CuNiCrSi Butt Joint. Metals, 8, 526

Srivastava, A. K., Maurya, N. K., Dixit, A. R., Dwivedi, S. P., Saxena, A., & Maurya, M. (2021). Experimental investigations of A359/Si3N4 surface composite produced by multi-pass friction stir processing. Materials Chemistry and Physics, 257, 123717

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dwivedi, S.P., Agrawal, R. & Sharma, S. Effect of Friction Stir Process Parameters on Mechanical Properties of Chrome Containing Leather Waste Reinforced Aluminium Based Composite. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 935–943 (2021). https://doi.org/10.1007/s40684-021-00312-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00312-z