Abstract

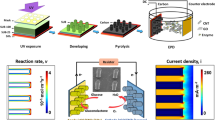

Enzymatic biofuel cells (EBFCs) that utilize glucose as fuel in a human body to produce electricity are being explored as promising alternatives to power implantable devices. However, some limitations need to be overcome to render such micro-electronic devices practically applicable. Here, we propose a microfluidic EBFC architecture with electrodes on both sides of the microchannel and its fabrication via stencil method. Multiwalled carbon nanotube (MWCNT) electrodes are fabricated on both sides of a Y-shaped microfluidic channel to reduce the effect of the depletion boundary layer and cross-diffusional mixing of the fuel and oxidant, which are functions of the distance from the microchannel inlet. Therefore, the microchannel length is reduced by half, while maintaining the same MWCNT electrode area. The microchannel is produced by polydimethylsiloxane (PDMS) casting whereas the electrodes are fabricated by a PDMS stencil, using MWCNT patterned on etched indium tin oxide glass. The electrodes are modified with glucose oxidase and laccase via direct covalent bonding. The cell performance is studied at different microchannel heights and flow rates, obtaining a maximum power and current density of 153 µW cm−2 and 450 µA cm−2, respectively, at a microchannel height of 450 µm and flow rate of 25 mL h−1. The double-layer EBFC shows a 23% improvement in the performance compared to a single-layer EBFC.

Similar content being viewed by others

Change history

24 May 2019

The original version of this article unfortunately contains a mistake. The acknowledgement section of the above article is incorrect. The correct acknowledgements are as follows:

References

Moehlenbrock, M. J., & Minteer, S. D. (2008). Extended lifetime biofuel cells. Chemical Society Reviews, 37(6), 1188–1196.

Shukla, A. K., et al. (2004). Biological fuel cells and their applications. Current Science, 87(4), 455–468.

Bullen, R. A., et al. (2006). Biofuel cells and their development. Biosensors and Bioelectronics, 21(11), 2015–2045.

Yahiro, A. T., Lee, S. M., & Kimble, D. O. (1964). Bioelectrochemistry: I. Enzyme utilizing bio-fuel cell studies. Biochimica et Biophysica Acta (BBA) Specialized Section on Biophysical Subjects, 88(2), 375–383.

Bockris, J., & Srinivasan, S. (1969). Fuel cells: Their electrochemistry. McGraw-Hill, NewYork.

Govil, G., & Saran, A. (1982). Biochemical fuel cells. Journal of the Indian Chemical Society, 59,1226–1228.

Palmore, G., & Whitesides, G. M. (1994). Microbial and enzymatic biofuel cells. ACS Symposium Series, 566, 271–290.

Halámková, L., et al. (2012). Implanted biofuel cell operating in a living snail. Journal of the American Chemical Society, 134(11), 5040–5043.

Vielstich, W., Yokokawa, H., & Gasteiger, H. A. (2009). Handbook of fuel cells: Fundamentals technology and applications. John Wiley: New Jersey.

Mohiuddin, M., et al. (2015). Transparent and flexible haptic actuator based on cellulose acetate stacked membranes. International Journal of Precision Engineering and Manufacturing, 16(7), 1479–1485.

Kim, H. J., Seo, K. J., & Kim, D. E. (2016). Investigation of mechanical behavior of single-and multi-layer graphene by using molecular dynamics simulation. International Journal of Precision Engineering and Manufacturing, 17(12), 1693–1701.

Zhou, J., & Yang, G. (2006). Nanohole fabrication using FIB, EB and AFM for biomedical applications. International Journal of Precision Engineering and Manufacturing, 7(4), 18–22.

Kim, J., Jia, H., & Wang, P. (2006). Challenges in biocatalysis for enzyme-based biofuel cells. Biotechnology advances, 24(3), 296–308.

Shin, Y. C., Novin, E., & Kim, H. (2015). Electrical and thermal conductivities of carbon fiber composites with high concentrations of carbon nanotubes. International Journal of Precision Engineering and Manufacturing, 16(3), 465–470.

Bae, K. M., et al. (2015). Thermobattery based on CNT coated carbon textile and thermoelectric electrolyte. International Journal of Precision Engineering and Manufacturing, 16(7), 1245–1250.

Suh, Y. D., et al. (2016). Selective electro—thermal growth of zinc oxide nanowire on photolithographically patterned electrode for microsensor applications. International Journal of Precision Engineering and Manufacturing Green Technology, 3(2), 173–177.

Rincon, R. A., et al. (2011). Enzymatic fuel cells: Integrating flow-through anode and air-breathing cathode into a membrane-less biofuel cell design. Biosensors and Bioelectronics, 27(1), 132–136.

Zebda, A., et al. (2009). Electrochemical performance of a glucose/oxygen microfluidic biofuel cell. Journal of Power Sources, 193(2), 602–606.

Choban, E. R., et al. (2004). Microfluidic fuel cell based on laminar flow. Journal of Power Sources, 128(1), 54–60.

Amatore, C., et al. (2007). Theory and experiments of transport at channel microband electrodes under laminar flows. 1. Steady-state regimes at a single electrode. Analytical chemistry, 79(22), 8502–8510.

Chen, F., Chang, M. H., & Lin, M. K. (2007). Analysis of membraneless formic acid microfuel cell using a planar microchannel. Electrochimica acta, 52(7), 2506–2514.

Choban, E. R., Waszczuk, P., & Kenis, P. J. A. (2005). Characterization of limiting factors in laminar flow-based membraneless microfuel cells. Electrochemical and Solid-State Letters, 8(7), A348–A352.

Zebda, A., et al. (2011). Enzyme-based microfluidic biofuel cell to generate micropower. Enzyme, 2, O2.

Zebda, A., et al. (2010). Membraneless microchannel glucose biofuel cell with improved electrical performances. Sensors and Actuators B Chemical, 149(1), 44–50.

T. D., Dang, T. D., et al. (2011). A novel simple preparation method of a hydrogel mold for PDMS micro-fluidic device fabrication. Journal of Micromechanics and Microengineering, 22(1), 015017.

Choi, J. H., et al. (2012). Micropatterning of neural stem cells and Purkinje neurons using a polydimethylsiloxane (PDMS) stencil. Lab on a Chip, 12(23), 5045–5050.

Beneyton, T., et al. (2013). Membraneless glucose/O2 microfluidic biofuel cells using covalently bound enzymes. Chemical Communications, 49(11), 1094–1096.

Farneth, W. E., & D’Amore, M. B., (2005). Encapsulated laccase electrodes for fuel cell cathodes. Journal of Electroanalytical Chemistry, 581(2), 197–205.

Bedekar, A. S., et al. (2007). Oxygen limitation in microfluidic biofuel cells. Chemical Engineering Communications, 195(3), 256–266.

Ferrigno, R., et al. (2002). Membraneless vanadium redox fuel cell using laminar flow. Journal of the American Chemical Society, 124(44), 12930–12931.

González-Guerrero, M. J., et al. (2013). Membraneless glucose/O2 microfluidic enzymatic biofuel cell using pyrolyzed photoresist film electrodes. Lab on a Chip, 13(15), 2972–2979.

Brunel, L., et al. (2007). Oxygen transport through laccase biocathodes for a membrane-less glucose/O2 biofuel cell. Electrochemistry Communications, 9(2), 331–336.

Tamaki, T., & Yamaguchi, T. (2006). High-surface-area three-dimensional biofuel cell electrode using redox-polymer-grafted carbon. Industrial and Engineering Chemistry Research, 45(9), 3050–3058.

Acknowledgements

This work was supported by the National Research Foundation of Korea Grant (NRF-2017R1A2B4004966 and NRF-2012K1A3A1A19038448) funded by the Korean Government (KMEST).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, H., Kim, C.M., Kim, S.Y. et al. Fabrication of Enzymatic Biofuel Cell with Electrodes on Both Sides of Microfluidic Channel. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 511–520 (2019). https://doi.org/10.1007/s40684-019-00056-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00056-x