Abstract

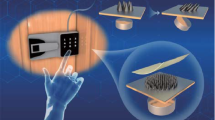

The triboelectric effect utilizes the electric potential of materials to generate an electrical output through electrostatic induction between the two oppositely charged surfaces, which grants them unique self-powered characteristics. By utilizing this effect, self-powered tactile sensors have been studied in the previous researches. However, the conventional triboelectric tactile sensors have drawbacks of limited dynamic range due to the decreasing sensitivity under increased applied pressures. Owing to this disadvantage, the triboelectric tactile sensor has not been extensively employed in smart manufacturing applications where a consistently high sensitivity within the dynamic range is preferred. In order to address this issue, a lightweight, compact, bio-friendly and highly sensitive self-powered triboelectric tactile sensor has been investigated based on the triboelectric effect. By integration of deformable foam layer, triboelectric tactile sensor is able to shift the dynamic range by 76–98 kPa without having to employ gain adjustment circuit board or modifying the properties of the sensor (geometric, materials, etc.). The proposed tactile sensor can be employed in various smart manufacturing applications in which light, self-powered, and high-performance tactile sensors are required to reduce the weight and energy consumption.

Similar content being viewed by others

Abbreviations

- VOC :

-

Open-circuit voltage (V)

- Pa :

-

Applied pressure/stress (Pa)

- Fa :

-

Applied force (N)

- Asensor :

-

Sensor area (m2)

- k:

-

Sensor stiffness (N/m)

- dL:

-

Deformation in the direction of the applied pressure (m)

- L0 :

-

Initial thickness of the sensor (m)

- εa :

-

Elastic strain

- E:

-

Elastic modulus (Pa)

- kPDMS :

-

PDMS layer stiffness (N/m)

- LPDMS0 :

-

Initial thickness of the PDMS layer (m)

- dLPDMS :

-

Deformation of the PDMS layer (m)

- kFoam :

-

Foam layer stiffness (N/m)

- LFoam0 :

-

Initial thickness of the foam layer (m)

- dLFoam :

-

Deformation of the foam layer (m)

- EPDMS :

-

Elastic modulus of the PDMS layer (Pa)

- EFoam :

-

Elastic modulus of the foam layer (Pa)

References

Ahn, S.-H. (2014). An evaluation of green manufacturing technologies based on research databases. International Journal of Precision Engineering and Manufacturing-Green Technology, 1(1), 5–9.

Kang, H. S., Lee, J. Y., Choi, S., Kim, H., Park, J. H., Son, J. Y., et al. (2016). Smart manufacturing: past research, present findings, and future directions. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(1), 111–128.

Park, Y.-L., Chen, B.-R., & Wood, R. J. (2012). Design and fabrication of soft artificial skin using embedded microchannels and liquid conductors. IEEE Sensors Journal, 12(8), 2711–2718.

Nie, B., Li, R., Brandt, J. D., & Pan, T. (2014). Microfluidic tactile sensors for three-dimensional contact force measurements. Lab on a Chip, 14(22), 4344–4353.

Hammond, F. L., Mengüc, Y., & Wood, R. J. (2014). Toward modular soft sensor-embedded glove for human hand motion and tactile pressure measurement. In IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2014), Chicago, IL, USA (pp. 4000–4007). IEEE

Ulmen, J., & Cutkosky, M. (2010). A robust, low-cost and low-noise artificial skin for human-friendly robots. In IEEE International Conference on Robotics and Automation, Anchorage, Alaska, USA (pp. 4836–4841).

Phan, S., Quek, Z. F., Shah, P., Shin, D., Ahmed, Z., Khatib, O., & Cutkosky M. (2011). Capacitive skin sensors for robot impact monitoring. In IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA (pp. 2992–2997).

Šekoranja, B., Bašić, D., Švaco, M., Šuligoj, F., & Jerbić, B. (2014). Human-robot interaction based on use of capacitive sensors. Procedia Engineering, 69, 464–468.

Kim, K., Lee, K. R., Kim, W. H., Park, K.-B., Kim, T.-H., Kim, J.-S., et al. (2009). Polymer-based flexible tactile sensor up to 32 x 32 arrays integrated with interconnection terminals. Sensors and Actuators A, 156(2), 284–291.

Pang, C., Lee, G.-Y., Kim, T.-I., Kim, S. M., Kim, H. N., Ahn, S.-H., et al. (2012). A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibers. Nature Materials, 11, 795–801.

Ma, C.-W., Hsu, L.-S., Kuo, J.-C., & Yang, Y.-J. (2015). A flexible tactile and shear sensing array fabricated using a novel buckypaper patterning technique. Sensors and Actuators A, 231, 21–27.

Park, J.-H., Lim, T.-W., Kim, S.-D., & Park, S.-H. (2016). Design and experimental verification of flexible plate-type piezoelectric vibrator for energy harvesting system. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(3), 253–259.

Wang, Z. L. (2014). Triboelectric nanogenerators as new energy technology and self-powered sensors—principles, problems, and perspectives. Faraday Discussions, 176, 447–458.

Büscher, G. H., Kõiva, R., Schürmann, C., Haschke, R., & Ritter, H. J. (2015). Flexible and stretchable fabric-based tactile sensor. Robotics and Autonomous Systems, 63(3), 244–252.

Siddiqui, S., Kim, D.-I., Roh, E., Duy, L. T., Trung, T. Q., Nguyen, M. T., et al. (2016). A durable and stable piezoelectric nanogenerator with nanocomposite and nanofibers embedded in an elastomer under high loading for a self-powered sensor system. Nano Energy, 30, 434–442.

Spanu, A., Pinna, L., Viola, F., Seminara, L., Valle, M., Bonfiglio, A., et al. (2016). A high-sensitivity tactile sensor based on piezoelectric polymer PVDF coupled to an ultra-low voltage organic transistor. Organic Electronics, Vo., 36, 57–60.

Anton, S., Farinholt, K., & Erturk, A. (2014). Piezoelectret foam-based vibration energy harvesting. Journal of Intelligent Material Systems and Structures, 25(14), 1681–1692.

Wang, S., Lin, L., & Wang, Z. L. (2015). Triboelectric nanogenerators as self-powered active sensors. Nano Energy, 11, 436–462.

Lin, L., Xie, Y., Wang, S., Wu, W., Niu, S., Wen, X., et al. (2013). triboelectric active sensor array for self-powered static and dynamic pressure detection and tactile imaging. ACS Nano, 7(9), 8266–8274.

Badi, N., Bensaoula, A., & Nair, M. (2013). Dynamic range and sensitivity of field emission pressure sensors with non-silicon membranes. Applied Surface Science, 285, 907–911.

Zhu, Y., Qin, M., Huang, J., Yi, Z., & Huang, Q.-A. (2016). Sensitivity improvement of a 2D MEMS thermal wind sensor for low-power applications. IEEE Sensors J., 16(11), 4300–4308.

Seol, M.-L., Lee, S.-H., Han, J.-W., Kim, D., Cho, G.-H., & Choi, Y.-K. (2015). Impact of contact pressure on output voltage of triboelectric nanogenerator based on deformation of interfacial structures. Nano Energy, 17, 63–71.

Luo, J., Fan, F. R., Zhou, T., Tang, W., Xue, F., & Wang, Z. L. (2015). Ultrasensitive self-powered pressure sensing system. Extreme Mechanics Letters, 2, 28–36.

Xia, X., Chen, J., Guo, H., Liu, G., Wei, D., Xi, Y., et al. (2017). Embedding variable micro-capacitors in polydimethylsiloxane for enhancing output power of triboelectric nanogenerator. Nano Research, 10(1), 320–330.

Hande, N. (2006). Long-term safety and efficacy of polyurethane foam-covered breast implants. Aesthetic Surgery Journal, 26(3), 265–274.

Genina, N., Holländer, J., Jukarainen, H., Mäkilä, E., Salonen, J., & Sandler, N. (2016). Ethylene vinyl acetate (EVA) as a new drug carrier for 3D printed medical drug delivery devices. European Journal of Pharmaceutical Sciences, 90, 53–63.

Wang, Z. (2011). Polydimethylsiloxane mechanical properties measured by macroscopic compression and nanoindentation technique. Graduate Theses and Dissertations.

Witkiewicz, W., & Zieliński, A. (2006). Properties of the polyurethane (PU) light foams. Advances in Materials Science, 6(2), 35–51.

Verdejo, R., & Mills, N. J. (2004). Heel-shoe interactions and the durability of EVA foam running-shoe midsoles. Journal of Biomechanics, 37(9), 1379–1386.

Oroszlány, Á., Nagy, P., & Kovács, J. G. (2015). Compressive properties of commercially available PVC foams intended for use as mechanical models for human cancellous bone. Acta Polytechnica Hungarica, 12(2), 89–101.

Acknowledgement

Dongun Lee and Jihoon Chung contributed equally to this work. This research was supported by the Chung-Ang University Research Scholarship Grants in 2014. This research was supported by Nano Material Technology Development Program through the National Research Foundation of Korea (NRF-2016M3A7B4910532).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, D., Chung, J., Yong, H. et al. A Deformable Foam-Layered Triboelectric Tactile Sensor with Adjustable Dynamic Range. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 43–51 (2019). https://doi.org/10.1007/s40684-019-00024-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00024-5