Abstract

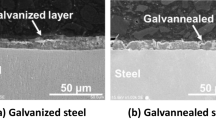

The electrically assisted brazing of a ferritic stainless steel with nickel-based filler metal is experimentally investigated. During electrically assisted brazing of a lap joint, the temperature of the joint is first rapidly increased to a brazing temperature and held nearly constant for a specific period using a pulsed electric current. Microstructural analysis results strongly suggest that the electric current during electrically assisted brazing enhances diffusion between the filler metal and the ferritic stainless steel, thus inducing significantly thicker diffusion zones compared with induction brazing. The mechanical test results show that the strength of the electrically assisted brazing joint is comparable to or even superior to those of the joint fabricated by induction brazing, while the process time of the electrically assisted brazing is significantly shorter than that of induction brazing.

Similar content being viewed by others

References

Mohandas, T., Reddy, G. M., and Naveed, M., “A Comparative Evaluation of Gas Tungsten and Shielded Metal Arc Weld of a Ferritic Stainless Steel,” Journal of Materials Processing Technology, Vol. 94, Nos. 2–3, pp. 133–140, 1999.

Kim, K.-H., Bang, H.-S., Ro, C.-S., and Bang, H.-S., “Influence of Preheating Source on Mechanical Properties and Welding Residual Stress Characteristics in Ultra Thin Ferritic Stainless Steel Hybrid Friction Stir Welded Joints,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 4, No. 4, pp. 393–400, 2017.

Taban, E., Deleu, E., Dhooge, A., and Kaluc, E., “Laser Welding of Modified 12% Cr Stainless Steel: Strength, Fatigue, Toughness, Microstructure and Corrosion Properties,” Materials and Design, Vol. 30, No. 4, pp. 1193–1120, 2009.

Yang, R.-T. and Chen, Z.-W., “A Study on Fiber Laser Lap Welding of Thin Stainless Steel,” International Journal of Precision Engineering and Manufacturing, Vol. 14, No. 2, pp. 207–214, 2013.

Shiue, R. K., Wu, S. K., and Hung, C. M., “Infrared Repair Brazing of 403 Stainless Steel with A Nickel-based Braze Alloy,” Metallurgical and Materials Transactions: A, Vol. 33, No. 6, pp. 1765–1773, 2002.

Ou, C. L., Liaw, D. W., Du, Y. C., and Shiue, R. K., “Brazing of 422 Stainless Steel using the AWS Classification BNi-2 Braze Alloy,” Journal of Materials Science, Vol. 41, No. 19, pp. 6353–6361, 2006.

Wu, X., Chandel, R. S., Pheow, S. H., and Li, H., “Brazing of Inconel X-750 to Stainless Steel 304 using Induction Process,” Materials Science and Engineering: A, Vol. 288, No. 1, pp. 84–90, 2000.

Lugscheider, E. and Partz, K. D., “High Temperature Brazing of Stainless Steel with Nickel-base Filler Metals BNi-2, BNi-5 and BNi-7,” Welding Journal, Vol. 62, No. 6, pp. 160–164, 1983.

Conrad, H., “Electroplasticity in Metals and Ceramics,” Materials Science and Engineering: A, Vol. 287, No. 2, pp. 276–287, 2000.

Li, Y., Yang, Y., and Feng, X., “Influence of Electric Current on Kirkendall Diffusion of Zn/Cu Couples,” Journal of Materials Science and Technology, Vol. 24, No. 3, pp. 410–414, 2008.

Kim, M.-J., Lee, K., Oh, K. H., Choi, I.-S., Yu, H.-H., et al., “Electric Current-Induced Annealing During Uniaxial Tension of Aluminum Alloy,” Scripta Materialia, Vol. 75, pp. 58–61, 2014.

Kim. M.-S., Vinh, N. T., Yu, H.-H., Hong, S.-T., Lee, H.-W., et al., “Effect of Electric Current Density on the Mechanical Property of Advanced High Strength Steels under Quasi-Static Tensile Loads,” International Journal of Precision Engineering and Manufacturing, Vol. 15, No. 6, pp. 1207–1213, 2014.

Nguyen-T., H.-D., Oh, H.-S., Hong, S.-T., Han, H. N., Cao, J., et al., “A Review of Electrically-Assisted Manufacturing,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 2, No. 4, pp. 365–376, 2015.

Thien, N. T., Hong, S.-T., Kim, M.-J., Han, H. N., Yang, D.-H., et al., “Electrically Assisted Bake Hardening of Complex Phase Ultra-High Strength Steels,” International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 2, pp. 225–231, 2016.

Oh, H.-S., Cho, H.-R., Park, H., Hong, S.-T., Chun, D.-M., et al., “Study of Electrically-Assisted Indentation for Surface Texturing,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 3, No. 2, pp. 161–165, 2016.

Xu, Z., Peng, L., and Lai, C., “Electrically Assisted Solid-State Pressure Welding Process of SS 316 Sheet Metals,” Journal of Materials Processing Technology, Vol. 214, No. 11, pp. 2212–2219, 2014.

Kim, W., Yeom, K.-H., Thien, N. T., Hong, S.-T., Min, B.-K., et al., “Electrically Assisted Blanking using the Electroplasticity of Ultra-High Strength Metal Alloys,” CIRP Annals–Manufacturing Technology, Vol. 63, No. 1, pp. 273–276, 2014.

Baranov, S. A., Staschenko, V. I., Sukhov, A. V., Troitskiy, O. A., and Tyapkin, A. V., “Electroplastic Metal Cutting,” Russian Electrical Engineering, Vol. 82, No. 9, pp. 477–479, 2011.

Ng, M. K., Li, L., Fan, Z., Go, R. X., Smith III, E. F., et al., “Joining Sheet Metals by Electrically-Assisted Roll Bonding,” CIRP Annals–Manufacturing Technology, Vol. 64, No. 1, pp. 273–276, 2015.

Davies, J. and Simpson, P., “Induction Heating Handbook,” McGraw-Hill, 1979.

Yu, C.-C., Su, P.-C., Bai, S. J., and Chuang, T.-H., “Nickel-Tin Solid-Liquid Inter-Diffusion Bonding,” International Journal of Precision Engineering and Manufacturing, Vol. 15, No. 1, pp. 143–147, 2014.

Atabaki, M. M., Wati, J. N., and Idris, J. “Transient Liquid Phase Diffusion Brazing of Stainless Steel 304,” Welding Journal, Vol. 92, pp. 57, 2013.

Thien, N. T., Jeong, Y.-H., Hong, S.-T., Kim, M.-J., Han, H. N., et al., “Electrically Assisted Tensile Behavior of Complex Phase Ultra-High Strength Steel,” International Journal of Precision Engineering and Manufacturing-Green Technology, Vol. 3, No. 4, pp. 325–333, 2016.

Kim, M.-J., Lee, M.-G., Hariharan, K., Hong, S.-T., Choi, I.-S., et al., “Electric Current-Assisted Deformation Behavior of Al-Mg-Si Alloy under Uniaxial Tension,” International Journal of Plasticity, Vol. 94, pp. 148–170, 2017.

Park, J.-W., Jeong, H.-J., Jin, S.-W., Kim, M.-J., Lee, K., et al., “Effect of Electric Current on Recrystallization Kinetics in Interstitial Free Steel and AZ31 Magnesium Alloy,” Materials Characterization, Vol. 133, pp. 70–76, 2017.

Molotskii, M. and Fleurov, V., “Magnetic Effects in Electroplasticity of Metals,” Physical Review B, Vol. 52, No. 22, pp. 15829–15834, 1995.

Khorram, A. and Ghoreishi, M., “Comparative Study on Laser Brazing and Furnace Brazing of Inconel 718 Alloys with Silver Based Filler Metal,” Optics & Laser Technology, Vol. 68, pp. 165–174, 2015.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Viet Tien Luu Ph.D. candidate of School of Mechanical Engineering, University of Ulsan. His research interest is advanced metal joining and forming.

Thi Kieu Anh Dinh Ph.D. candidate of School of Mechanical Engineering, University of Ulsan. Her research interest is advanced metal forming.

Hrishikesh Das Postdoctoral researcher of School of Mechanical Engineering, University of Ulsan. His research interest is friction stir welding.

Ju-Ri Kim M.S. graduate of School of Mechanical Engineering, University of Ulsan. She currently works for Hyundai Rotem Company. Her research interest is solid state joining.

Sung-Tae Hong Professor of School of Mechanical Engineering, University of Ulsan. His research interest is advanced metal forming and solid state joining.

Hyun-Min Sung Associate research engineer in Materials & Production engineering Research Institute, LG electronics. His research interest is structural materials.

Heung Nam Han Professor in Department of Materials Science & Engineering, Seoul National University. His research interest is the mechanical behavior and microstructure for materials.

Rights and permissions

About this article

Cite this article

Luu, V.T., Dinh, T.K.A., Das, H. et al. Diffusion Enhancement during Electrically Assisted Brazing of Ferritic Stainless Steel Alloys. Int. J. of Precis. Eng. and Manuf.-Green Tech. 5, 613–621 (2018). https://doi.org/10.1007/s40684-018-0063-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-018-0063-0