Abstract

The realization of lubricant free forming processes is motivated by an increasing demand for resource efficiency and higher environmental standards. Further potentials are the reduction of production steps and time. The dry conditions lead to an intensive interaction between tool and workpiece. Increasing friction and wear are the consequences. One approach to face these challenges is the implementation of tailored tool surfaces. Within this study the behavior of different tool surfaces under dry and lubricated conditions is investigated. In this regards, a flat strip drawing test was conducted to determine the friction coefficients depending on the tool surface properties resulting from various machining processes. Furthermore, a surface characterization before and after the experiments was performed to gain knowledge about the wear mechanisms. The tests series with dry strips lead to a higher friction level. Furthermore, the results show that the friction can be reduced when the grinding marks are orientated transversal to the drawing direction. A further friction reduction is achieved when applying polished tools.

Article PDF

Similar content being viewed by others

Abbreviations

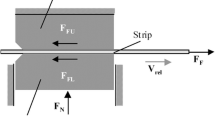

- m:

-

Amount of lubrication

- pN :

-

Normal pressure

- vrel :

-

Relative velocity

- n:

-

Number of repetition

- FF :

-

Friction force

- FN :

-

Normal force

- FFU :

-

Upper friction force

- FFL :

-

Lower friction force

- μ :

-

Friction coefficient

- Rz:

-

Averaged roughness height

- λ c :

-

Cut off length

- λ S :

-

Short-wave profile filter

- lr :

-

Sampling length

- ln :

-

Measuring length

References

Makinouchi, A. and Kawka, M., “Prediction of Geometrical Defects in Sheet Metal Forming Processes by Semi-Implicit FEM,” Studies in Applied Mechanics, Vol. 43, pp. 265–281, 1995.

Kirkhorn, L., Frogner, K., Andersson, M., and Ståhl, J.-E., “Improved Tribotesting for Sheet Metal Forming,” Procedia CIRP, Vol. 3, pp. 507–512, 2012.

Bay, N., Azushima, A., Groche, P., Ishibashi, I., Merklein, M., et al., “Environmentally Benign Tribo-Systems for Metal Forming,” CIRP Annals-Manufacturing Technology, Vol. 59, No. 2, pp. 760–780, 2010.

Vollertsen, F. and Schmidt, F., “Dry Metal Forming: Definition, Chances and Challenges,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 1, pp. 59–62, 2014.

Kirkhorn, L., Bushlya, V., Andersson, M., and Ståhl, J.-E., “The Influence of Tool Steel Microstructure on Friction in Sheet Metal Forming,” Wear, Vol. 302, No. 1–2, pp. 1268–1278, 2013.

Meiler, M. and Jaschke, H., “Lubrication of Aluminium Sheet Metal within the Automotive Industry,” Advanced Materials Research, Vol. 6–8, pp. 551–558, 2005.

Birkert, A., Haage, S., and Straub, M., “Umformtechnische Herstellung Komplexer Karosserieteile: Auslegung von Ziehanlagen,” Springer-Verlag, pp. 179–180 and 207–209, 2013.

Severo, V., Vilhena, L., Silva, P., Dias, J., Becker, D., et al., “Tribological Behaviour of W-Ti-N Coatings in Semi-Industrial Strip-Drawing Tests,” Journal of Materials Processing Technology, Vol. 209, No. 10, pp. 4662–4667, 2009.

Batalha, G. and Stipkovic, F. M., “Quantitative Characterization of the Surface Topography of Cold Rolled Sheets-New Approaches and Possibilities,” Journal of Materials Processing Technology, Vol. 113, No. 1, pp. 732–738, 2001.

Bowden, F. P., Tabor, D., and Freitag, E. H., “Reibung und Schmierung Fester Körper,” Springer Berlin Heidelberg, pp. 13–145, 1959.

Leu, D.-K., “A Simple Dry Friction Model for Metal Forming Process,” Journal of Materials Processing Technology, Vol. 209, No. 5, pp. 2361–2368, 2009.

Hol, J., Alfaro, M. C., De Rooij, M., and Meinders, T., “Advanced Friction Modeling for Sheet Metal Forming,” Wear, Vol. 286–287, pp. 66–78, 2012.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Merklein, M., Andreas, K. & Steiner, J. Influence of tool surface on tribological conditions in conventional and dry sheet metal forming. Int. J. of Precis. Eng. and Manuf.-Green Tech. 2, 131–137 (2015). https://doi.org/10.1007/s40684-015-0017-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-015-0017-8