Abstract

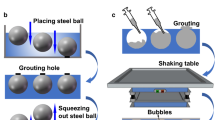

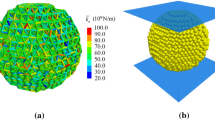

The relationship between the microcracks of a single particle and the crushing strength was studied by virtual experiments. The three-dimensional profile of a single particle was obtained by CT-scanning technology. The particle bonding model is used to fill the three-dimensional contour to construct virtual particles, and the virtual crushing experiment is carried out by discrete element method. The rationality of the parameters used in the contact model and the reliability of the virtual crushing test results are determined from the perspective of the macroscopic crushing condition of a single particle and the force–displacement curve. The loading speed of the virtual crushing test is set to 0.01 m/s. The influence of microcracks on the Weibull distribution of crushing strength is considered from three aspects: quantity, location and direction. The characteristic strength of Weibull distribution of basalt particles is positively correlated with the number of microcracks. The Weibull modulus of the five groups of virtual particles with different numbers of microcracks is less than 14.5, indicating that the strength distribution of the virtual particles is more discrete. Compared with the microcrack angle, the position of the microcrack has a greater influence on the crushing strength of the particles.

Similar content being viewed by others

Data availability statement

All data, models, and code generated or used during the study appear in the published article.

References

Einav I (2007) Breakage mechanics—part I: theory. J Mech Phys Solids 55(6):1274–1297

Einav I, Guillard F (2018) Tracking time with ricequakes in partially soaked brittle porous media. Sci Adv 4(10):eaat6961

Ouhbi N, Voivret C, Perrin G, Roux J-N (2017) 3D particle shape modelling and optimization through proper orthogonal decomposition. Granul Matter 19(4):86

Zhou X, Ma G, Zhang Y (2019) Grain size and time effect on the deformation of rockfill dams: a case study on the Shuibuya CFRD. Geotechnique 69(7):606–619

Zhou B, Wang J, Wang H (2014) A new probabilistic approach for predicting particle crushing in one-dimensional compression of granular soil. Soils Found 54(4):833–844

Huang Q, Zhou W, Ma G, Mei J, Xu K (2021) Investigation of the grain breakage behaviour of 2D granular materials with disordered pore distribution. Comput Part Mech 8(5):1033–1045

Zhu Z, Wang J, Wu M (2022) DEM simulation of particle crushing in a triaxial test considering the influence of particle morphology and coordination number. Comput Geotech 148

Wei J, Lu S, Li J (2013) Experimental study on performance of large stone permeable asphalt mixtures. In: 2nd Global conference on civil, structural and environmental engineering (GCCSEE 2013), Shenzhen, p 76

Yuan G, Hao P, Li D, Pan J, Dong S (2020) Optimization design and verification of large stone porous asphalt mixes gradation using compressible packing model. Construct Build Mater 230:116903

Qian G, Hu C, Yu H, Gong X (2020) Case study: ten year field performance evaluation of flexible base asphalt pavement design in heavy load condition. J Mater Civ Eng 32(7):04020187

Yang L, Hu Y, Zhang H (2020) Comparative study on asphalt pavement rut based on analytical models and test data. Int J Pavement Eng 21(6):781–795

Zhang R, Tang N, Zhu N, Zeng J, Bi Y, Xi Y (2022) Environmental and economic comparison of semi-rigid and flexible base asphalt pavement during construction period. J Clean Prod 340:130791

Chen B, Zhang X, Yu J, Wang Y (2017) Impact of contact stress distribution on skid resistance of asphalt pavements. Constr Build Mater 133:330–339

El-Tahan D, Gabr A, El-Badawy S, Shetawy M (2018) Evaluation of recycled concrete aggregate in asphalt mixes. Innov Infrastruct Solut 3(1):20

Souza LT, Kim Y-R, Souza FV, Castro LS (2012) Experimental testing and finite-element modeling to evaluate the effects of aggregate angularity on bituminous mixture performance. J Mater Civ Eng 24(3):249–258

Jansen U, Stoyan D (2000) On the validity of the Weibull failure model for brittle particles. Granul Matter 2(4):165–170

Le Pen LM, Powrie W, Zervos A, Ahmed S, Aingaran S (2013) Dependence of shape on particle size for a crushed rock railway ballast. Granul Matter 15(6):849–861

Lim WL, McDowell GR, Collop AC (2004) The application of Weibull statistics to the strength of railway ballast. Granul Matter 6(4):229–237

Nakata Y, Hyde AFL, Hyodo M, Murata H (1999) A probabilistic approach to sand particle crushing in the triaxial test. Geotechnique 49(5):567–583

Shao X-q, Chi S-c, Tao Y, Zhou X-x (2020) DEM simulation of the size effect on the wetting deformation of rockfill materials based on single-particle crushing tests. Comput Geotech 123:103429

Zhao X, Zhu J, Jia Y, Colliat J-B, Bian H, Zhang Q (2022) Experimental and numerical study of size effects on the crushing strength of rockfill particles. Int J Numer Anal Meth Geomech 46(11):2060–2086

Zhao X, Zhu J, Wu Y, Jia Y, Colliat J-B, Bian H (2022) A numerical study on the influence of coordination number on the crushing of rockfill materials. Rock Mech Rock Eng 55(10):6279–6300

Mahbub A, Haque A (2016) X-ray computed tomography imaging of the microstructure of sand particles subjected to high pressure one-dimensional compression. Materials 9(11):890

Liu G-Y, Xu W-J, Sun Q-C, Govender N (2020) Study on the particle breakage of ballast based on a GPU accelerated discrete element method. Geosci Front 11(2):461–471

Tavares LM, Andre FP, Potapov A, Maliska C Jr (2020) Adapting a breakage model to discrete elements using polyhedral particles. Powder Technol 362:208–220

Tavares LM, Rodriguez VA, Sousani M, Padros CB, Ooi JY (2021) An effective sphere-based model for breakage simulation in DEM. Powder Technol 392:473–488

Bai Q-S, Tu S-H, Zhang C (2016) DEM investigation of the fracture mechanism of rock disc containing hole(s) and its influence on tensile strength. Theor Appl Fract Mech 86:197–216

Gui YL, Zhao ZY, Zhang C, Ma SQ (2017) Numerical investigation of the opening effect on the mechanical behaviours in rocks under uniaxial loading using hybrid continuum-discrete element method. Comput Geotech 90:55–72

Han DD, Liu GQ, Xi YF, Zhao YL (2022) Theoretical analysis on the measurement accuracy of embedded strain sensor in asphalt pavement dynamic response monitoring based on FEM. Struct Control Health Monit 29(12):e2057

Han DD, Xi YF, Xie YC, Li ZC, Zhao YL (2023) 3D Virtual reconstruction of asphalt mixture microstructure based on rigid body dynamic simulation. Int J Pavement Eng 24(1):2165654

Huang Y-H, Yang S-Q, Ranjith PG, Zhao J (2017) Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: experimental study and particle flow modeling. Comput Geotech 88:182–198

Liu G, Han D, Zhao Y, Zhang J (2022) Effects of asphalt mixture structure types on force chains characteristics based on computational granular mechanics. Int J Pavement Eng 23(4):1008–1024

Xu J, Kong C, Xu T (2022) Displacemental and mesomechanical responses of semi-flexible pavement based on discrete element method. Int J Pavement Res Technol 15:1484–1497

Xu J, Kong C, Xu T (2022) Effects of deposition states and distribution regularity of clogging substances on pore clogging behaviors of double-layer drainage asphalt pavement. Construct Build Mater 314:125701

Zhang T, Huang W (2022) DEM analysis of single-particle crushing considering the inhomogeneity of material properties. Acta Mech Solida Sin 35(1):26–39

McDowell GR (2001) Statistics of soil particle strength. Geotechnique 51(10):897–900

Ovalle C, Frossard E, Dano C, Hu W, Maiolino S, Hicher P-Y (2014) The effect of size on the strength of coarse rock aggregates and large rockfill samples through experimental data. Acta Mech 225(8):2199–2216

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech Trans ASME 18(3):293–297

Xu K, Zhou W, Ma G, Chang X, Yang L (2018) Review of particle breakage simulation based on DEM. Chin J Geotech Eng 40(5):880–889

Horabik J, Wiacek J, Parafiniuk P, Stasiak M, Banda M, Kobylka R, Molenda M (2020) Discrete element method modelling of the diametral compression of starch agglomerates. Materials 13(4):932

Sun W, Wu S-c, Zhou Y, Zhou J-x (2019) Comparison of crack processes in single-flawed rock-like material using two bonded-particle models under compression. Arab J Geosci 12(5):156

Huang Q, Zhou W, Ma G, Ng T-T, Xu K (2020) Experimental and numerical investigation of Weibullian behavior of grain crushing strength. Geosci Front 11(2):401–411

Brosh T, Kalman H, Levy A, Peyron I, Ricard F (2014) DEM-CFD simulation of particle comminution in jet-mill. Powder Technol 257:104–112

Cavarretta I, O’Sullivan C, Coop MR (2017) The relevance of roundness to the crushing strength of granular materials. Geotechnique 67(4):301–312

Huang J, Xu S, Yi H, Hu S (2014) Size effect on the compression breakage strengths of glass particles. Powder Technol 268:86–94

McDowell GR, Amon A (2000) The application of Weibull statistics to the fracture of soil particles. Soils Found 40(5):133–141

Kharaghani A, Metzger T, Tsotsas E (2011) A proposal for discrete modeling of mechanical effects during drying, combining pore networks with DEM. AIChE J 57(4):872–885

Kwok CY, Bolton MD (2013) DEM simulations of soil creep due to particle crushing. Geotechnique 63(16):1365–1376

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 52078132) and the Scientific Research Foundation of Graduate School of Southeast University. The authors gratefully acknowledge their financial support. In addition, thank you to all the authors in the following references.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Liu, B., Han, D. et al. Study on the influence of microcracks of coarse aggregate with specific particle size on crushing strength. Comp. Part. Mech. 11, 705–719 (2024). https://doi.org/10.1007/s40571-023-00648-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00648-0