Abstract

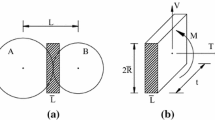

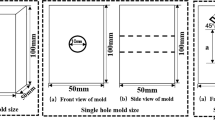

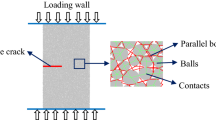

In this paper, the mechanical properties, acoustic emission characteristics and damage evolution laws of rocks with different defect holes are explored by considering the influence of the location of defect holes. The rock models with different defect hole locations are constructed based on particle flow code. The influence of different defect hole positions on the mechanical characteristics, acoustic emission (AE) characteristics, damage evolution process, and failure modes of rock models are discussed. The research result shows that the elastic modulus (E) of numerical models with different defect hole locations has little change; the uniaxial compressive strength (UCS) of the model with defect hole at the center of the model is larger than the UCS of the defect hole at the boundary of the model; the evolution law of acoustic emission can be roughly divided into three stages: the silent emission stage, the slow development stage and the rapid development stage. The position of defect holes has little influence on the first two stages, but has obvious influence on the third stage, such as the intensity of acoustic emission (maximum AE counts) and strain range. The position of different defect holes has little influence on the first two stages of damage evolution of rock models, but mainly affects the rapid damage stage. The position of the defect hole has little effect on the crack initiation position of the rock, both in the upper and lower directions of the circular hole. However, the location of the defect hole will affect the failure process of the rock.

Similar content being viewed by others

Data availability

The data used to support the findings of this study are included in the article.

References

Jia P, Tang CA (2008) Numerical study on failure mechanism of tunnel in jointed rock mass. Tunn Undergr Space Technol 23(5):500–507

Wang X, Tian LG (2018) Mechanical and crack evolution characteristics of coal–rock under different fracture-hole conditions: a numerical study based on particle flow code. Environ Earth Sci 77(8):1–10

Wang C, Tannant DD, Lilly PA (2003) Numerical analysis of the stability of heavily jointed rock slopes using PFC2D. Int J Rock Mech Min Sci 40(3):415–424

Yang SQ , Huang YH , Tian WL (2019) Effect of high temperature on deformation failure behavior of granite specimen containing a single fissure under uniaxial compression[J]. Rock Mech Rock Eng 52(7):2087–2107. https://doi.org/10.1007/s00603-018-1725

Liang P, Gao Y (2020) Numerical investigation on cracking behavior of granite with intersecting two-flaws: a flat-joint modeling method. Lat Am J Solids Struct 17(4):e280

Yugo N, Shin W (2015) Analysis of blasting damage in adjacent mining excavations. J Rock Mech Geotech Eng 7(3):282–290

Singh M, Rao KS, Ramamurthy T (2002) Strength and deformational behaviour of a jointed rock mass. Rock Mech Rock Eng 35(1):45–64

Jiang Y, Tanabashi Y, Li B, Xiao J (2006) Influence of geometrical distribution of rock joints on deformational behavior of underground opening. Tunn Undergr Space Technol 21(5):485–491

Yang XX, Jing HW, Tang CA, Yang SQ (2017) Effect of parallel joint interaction on mechanical behavior of jointed rock mass models. Int J Rock Mech Min Sci 92:40–53

Han GS, Jing HW, Su HJ, Zhu TT, Du MR, Xiong F, Wu JY (2017) Experimental study on compressive strength and fracture characteristics of sandstone containing double circular cavities. J China Coal Soc 42(4):871–878

Chen M, Yang SQ, Ranjith PG, Zhang YC (2020) Cracking behavior of rock containing non-persistent joints with various joints inclinations. Theor Appl Fract Mech 109:102701

Lin Q, Cao P, Meng J, Cao R, Zhao Z (2020) Strength and failure characteristics of jointed rock mass with double circular holes under uniaxial compression: Insights from discrete element method modelling. Theor Appl Fract Mech 109:102692

Chen Z, Xu L, Shang Y (2021) Influence of joint angle on the acoustic emission evolution characteristics and energy dissipation rule of rock mass. Geotech Geol Eng 39(2):1621–1635

Chen S, Xia Z, Feng F, Yin D (2021) Numerical study on strength and failure characteristics of rock samples with different hole defects. Bull Eng Geol Env 80:1523–1540

Bu F, Xue L, Zhai M, Huang X, Dong J, Liang N, Xu C (2022) Evaluation of the characterization of acoustic emission of brittle rocks from the experiment to numerical simulation. Sci Rep 12(1):498

Khazaei C, Hazzard J, Chalaturnyk R (2015) Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput Geotech 67:94–102

Zhai M, Xue L, Bu F, Yang B, Ding H (2022) Microcracking behaviors and acoustic emission characteristics of granite subjected to direct shear based on a novel grain-based model. Comput Geotech 151:104955

Bu F, Xue L, Zhai M, Xu C, Cui Y (2022) Numerical investigation of the scale effects of rock bridges. Rock Mech Rock Eng 55(9):5671–5685

Dou L, Yang K, Chi X (2021) Fracture behavior and acoustic emission characteristics of sandstone samples with inclined precracks. Int J Coal Sci Technol 8(1):77–87

Wang X, Wen Z, Jiang Y, Huang H (2018) Experimental study on mechanical and acoustic emission characteristics of rock-like material under non-uniformly distributed loads. Rock Mech Rock Eng 51(3):729–745

He MC, Miao JL, Feng JL (2010) Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int J Rock Mech Min Sci 47(2):286–298

Zhang Q, Zhang XP, Yang SQ (2021) A numerical study of acoustic emission characteristics of sandstone specimen containing a hole-like flaw under uniaxial compression. Eng Fract Mech 242:107430

Moradian ZA, Ballivy G, Rivard P et al (2010) Evaluating damage during shear tests of rock joints using acoustic emissions. Int J Rock Mech Min Sci 47(4):590–598

Liu JP, Li YH, Xu SD (2014) Estimation of cracking and damage mechanisms of rock specimens with precut holes by moment tensor analysis of acoustic emission. Int J Fract 188:1–8

Zhai M, Xue L, Bu F, Yang B, Huang X, Liang N, Ding H (2022) Effects of bedding planes on progressive failure of shales under uniaxial compression: insights from acoustic emission characteristics. Theor Appl Fract Mech 119:103343

Li P, Ren FH, Cai MF (2019) Investigating the mechanical and acoustic emission characteristics of brittle failure around a circular opening under uniaxial loading[J]. Int J Min Metal Mat 26(10):1217–1230. https://doi.org/10.1007/s12613-019-1887-5

Li P, Cai M, Guo Q, Ren F (2022) Investigation on acoustic emission characteristics of hole-joint contained granite under a compressive disturbance: experimental insights. Lithosphere 2022(Special 11):359

Itasca Consulting Group Inc (2014) PFC (particle flow code). Version 5.0. ICG, Minneapolis

Cho NA, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010

Zhang Q, Zhu H, Zhang L, Ding X (2011) Study of scale effect on intact rock strength using particle flow modeling. Int J Rock Mech Min Sci 48(8):1320–1328

Liu WR, Liu JK, Zhu C (2019) Multi-scale effect of acoustic emission characteristics of 3D rock damage. Arab J Geosci 12(22):1–13

Yang S, Liu X, Li Y (2012) Experimental analysis of mechanical behavior of sandstone containing hole and fissure under uniaxial compression. Chin J Rock Mech Eng 31(2):3539–3546

Wen Z, Wang X, Chen L, Lin G, Zhang H (2017) Size effect on acoustic emission characteristics of coal-rock damage evolution. Adv Mater Sci Eng 2017:1–8

Zhao ZL, Wang X, Wen ZJ (2018) Analysis of rock damage characteristics based on particle discrete element model. Geotech Geol Eng 36:897–904

Hazzard JF, Young RP (2002) Moment tensors and micromechanical models. Tectonophysics 356(1–3):181–197

Lemaitre J, Sermage JP, Desmorat R (1999) A two scale damage concept applied to fatigue. Int J Fract 97(1):67–81

Wang X, Wu N, Li H, Yan Y (2022) Influence of joint angle on the instability failure characteristics and AE evolution law of underground caverns. Eur J Environ Civ Eng 26(9):4055–4072

Wang Z, Li Y, Cai W, Zhu W, Kong W, Dai F, Wang C, Wang K (2021) Crack propagation process and acoustic emission characteristics of rock-like specimens with double parallel flaws under uniaxial compression. Theor Appl Fract Mech 114:102983

Zhao Z, Jing H, Shi X (2019) Experimental and numerical study on mechanical and fracture behavior of rock-like specimens containing pre-existing holes flaws[J]. E J Environ Civil Eng 1–21

Acknowledgements

This research was funded by The National Key Research and Development Program of China (No.2021YFB2601000) and The Hebei Province Key Research and Development Program of China (No. 21374101D).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rong, L., Hu, J. & Li, H. Influence of defect hole location on acoustic emission characteristics and damage evolution of rocks: a numerical study based on particle flow code. Comp. Part. Mech. 10, 1943–1954 (2023). https://doi.org/10.1007/s40571-023-00599-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-023-00599-6