Abstract

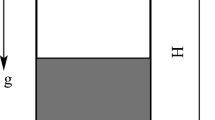

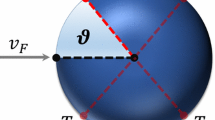

In this study, the hydrodynamic simulation of molybdenite powder fluidized bed has been carried out analytically and numerically. The ultimate goal of this research was to design a fluidized bed dryer and roaster for molybdenite powder of Khaton-Abad Molybdenite Factory. The Euler-Euler approach was used to model a fluidized bed to predict the minimum fluidization velocity and behavior of solids in the molybdenite fluidized bed roaster by using the CFD package ANSYS FLUENT. The minimum fluidization velocity, which is one of the most critical parameters for the design and operation of fluidized beds, was obtained analytically and numerically. Numerical result shows that the minimum fluidization velocity for spherical molybdenite particles of 0.0001 m in size and density of 4600 kg/m3 is 2 cm/s at a temperature of 300 K. The computational geometry of a 2D fluidized bed had a height of 0.5 m and a width of 0.05 m. Analytical results show that the minimum fluidization velocity at 870 K is about half of the minimum fluidization velocity at 300 K. A correlation has been derived from the Ergun equation and the hypothesis of Wen and Yu for predicting the minimum fluidization velocity of irregular and spherical particles at low particle Reynolds numbers. The computational results and the prediction with the derived correlation were in good agreement with the experimental data for various types and diameters of particles.

Similar content being viewed by others

References

Gupta CK (1992) Extractive metallurgy of molybdenum. Routledge, New York

Yang W-c (2003) Handbook of fluidization and fluid-particle systems. CRC Press, Boca Raton

Gupta CK, Sathiyamoorthy D (1998) Fluid bed technology in materials processing. CRC Press, Boca Raton

Kunii D, Levenspiel O (2013) Fluidization engineering. Elsevier, Amsterdam

Passos M, Barrozo M, Mujumdar A (2013) Fluidization engineering practice. Laval, Canada

Jang J, Arastoopour H (2013) CFD simulation of different-scaled bubbling fluidized beds.

Taghipour F, Ellis N, Wong C (2005) Experimental and computational study of gas–solid fluidized bed hydrodynamics. Chem Eng Sci 60(24):6857–6867

Armstrong L, Gu S, Luo K (2010) Study of wall-to-bed heat transfer in a bubbling fluidised bed using the kinetic theory of granular flow. Int J Heat Mass Transf 53(21–22):4949–4959

Bigot V, Guyot I, Bataille D, Roustan M (1990) Possibilities of use of two sensors depression metrological techniques and fiber optics, to characterize the hydrodynamics of a fluidized bed triphasic. Recent Adv Process Eng 4:143–156

Merchant F et al (1987) A novel technique for measuring solute diffusivities in entrapment matrices used in immobilization. Biotechnol Bioeng 30(8):936–945

Briens LA, Ellis N (2005) Hydrodynamics of three-phase fluidized bed systems examined by statistical, fractal, chaos and wavelet analysis methods. Chem Eng Sci 60(22):6094–6106

Luo X, Jiang P, Fan LS (1997) High-pressure three-phase fluidization: Hydrodynamics and heat transfer. AIChE J 43(10):2432–2445

Bhatia V, Epstein N (1974) Three phase fluidization: a generalized wake model. Fluidiz Appl, pp 380–392

Jena H, Roy G, Biswal K (2008) Studies on pressure drop and minimum fluidization velocity of gas–solid fluidization of homogeneous well-mixed ternary mixtures in un-promoted and promoted square bed. Chem Eng J 145(1):16–24

Ishii M. (1975) Thermo-Fluid Dynamic Theory of Two-Phase Flow., volume 22 of Direction des études et recherches d’électricité de France. Eyrolles, Paris.

Gidaspow D (1994) Multiphase flow and fluidization: continuum and kinetic theory descriptions. Academic Press, Cambridge

Cornelissen JT et al (2007) CFD modelling of a liquid–solid fluidized bed. Chem Eng Sci 62(22):6334–6348

Zhou Q, et al (2011) A CFD study on the effect of bed thickness in an internally circulating fluidized bed. Indus Fluid S Afr, 161–173.

Wilkomirsky IA (1974) Recirculating fluidized bed process for the roasting of molybdenite concentrates. University of British Columbia.

Wilkomirsky IA, Watkinson AP, Brimacombe JK (1976) Production of molybdenum trioxide from molybdenite in a fluidized bed. Google Patents.

Doheim M, MZ AW, SA, R (1975) Fluidized-bed roasting of molybdenite

Doheim MA, Abdel-Wahab MZ, Rassoul SA Fluidized bed roasting of molybdenite-effect of operating variables. Metallurg Trans B. 7B: 477.

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48:89–94

Wen CY (1966) Mechanics of fluidization. Chem Eng Prog Symp Ser

Manifar S (2013) Flow enhancement of ginseng and other fine powders with rotating and conventional fluidized bed

Delebarre A (2004) Revisiting the Wen and Yu equations for minimum fluidization velocity prediction. Chem Eng Res Des 82(5):587–590

Sathiyamoorthy D, Rao CS, Rao MR (1988) Effect of distributors on heat transfer from immersed surfaces in gas fluidised beds. Chem Eng J 88(Materials Science):2

Allamagny P (ed) (1976) Gas encyclopedia. Elsevier, Amsterdam

Fu Z et al (2019) Minimum fluidization velocity growth due to bed inventory increase in an Air Dense Medium Fluidized Bed. Chem Eng J 359:1372–1378

Zhou CY (2019) Density adjustment in gas-solid fluidized bed for beneficiation using geldart a dense medium (in Chinese). China University of Mining & Technology, Xuzhou

Turrado S, Fernández JR, Abanades JC (2018) Determination of the solid concentration in a binary mixture from pressure drop measurements. Powder Technol 338:608–613

Chladek J et al (2018) Fluidized bed classification of particles of different size and density. Chem Eng Sci 177:151–162

Xu CC, Zhu J (2008) Prediction of the minimum fluidization velocity for fine particles of various degrees of cohesiveness. Chem Eng Commun 196(4):499–517

Zhu Q, Zhang L, Hao W (2021) Determining minimum fluidization velocity in magnetized fluidized bed with Geldart-B particles. Powder Technol 389:85–95

Acknowledgements

This work would not have been possible without the financial support of the Shahrbabak Copper Complex Company. I am especially indebted to Mr. Mohammad Yavarzade, M.Sc. of the Department of research and development.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shahrbabaki, A.S., Kalantar, V. & Mansouri, S.H. Analytical and numerical considerations of the minimum fluidization velocity of the molybdenite particles. Comp. Part. Mech. 10, 769–776 (2023). https://doi.org/10.1007/s40571-022-00528-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-022-00528-z