Abstract

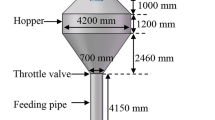

The velocity distribution law of coke particles in the rotating chute of a blast furnace is the key factor determining the three-dimensional shape of the burden surface, and it is of great significance to improve the charging operation of blast furnace and realize energy saving and emission reduction. To analyze the velocity distribution law of coke in the chute, a 1:8 bell-less blast furnace based on the discrete element method is first established. Then, a coordinate transformation method is proposed to obtain the position and velocity information of the coke relative to the rotating chute. Finally, the movement trend and velocity distribution law of coke in the chute are analyzed. Results indicate that the velocity distribution of coke has apparent stratification. When the chute is stationary, the velocity is greater, while the coke is near the chute symmetry or farther from the chute edge. When the chute is rotating, the Z-axis velocity of the coke with a large radial movement distance is smaller than that of the coke with a small radial movement distance, but the radial velocity of the coke with a large radial movement distance is greater than that of the coke with a large radial movement distance.

Similar content being viewed by others

References

Huang J, Chen Z, Jiang Z, Gui W (2020) 3D topography measurement and completion method of blast furnace burden surface using high-temperature industrial endoscope. IEEE Sens J 20(12):6478–6491

Pan D, Jiang Z, Chen Z, Jiang K, Gui W (2020) Compensation method for molten iron temperature measurement based on heterogeneous features of infrared thermal images. IEEE Trans Ind Inform 16(11):7056–7066

Jiménez J, Mochon J, De Ayala J (2004) Mathematical model of gas flow distribution in a scale model of a blast furnace shaft. ISIJ Int 44(3):518–526

Yu Y, Bai C, Zhang Z, Wang F, Lv D, Pan C (2009) Theoretical calculation and validation of burden trajectory in bell-less top blast furnace. Ironmak Steelmak 36(7):505–508

Ueda S, Natsui S, Fan Z, Nogami H, Soda R, Kano J, Inoue R, Ariyama T (2010) Influences of physical properties of particle in discrete element method on descending phenomena and stress distribution in blast furnace. ISIJ Int 50(7):981–986

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Geotechnique 29(1):47–65

Yu Y, Saxén H (2011) Analysis of rapid flow of particles down and from an inclined chute using small scale experiments and discrete element simulation. Ironmak Steelmak 38(6):432–441

Yu Y, Saxén H (2012) Flow of pellet and coke particles in and from a fixed chute. Ind Eng Chem Res 51(21):7383–7397

Sun C, Xu J, Liao Z, Xu Y, Kou M, Wen L (2019) Causes of particle trajectory fluctuation on the rotating chute in circumferential direction at bell-less top with parallel type hoppers. ISIJ Int 59(9):1527–1533

Govender N, Wilke D, Wu C, Tuzun U, Kureck H (2019) A numerical investigation into the effect of angular particle shape on blast furnace burden topography and percolation using a GPU solved discrete element mode. Chem Eng Sci 204:9–26

Mio H, Narita Y, Nakano K, Nomura S (2020) Validation of the burden distribution of the 1/3-scale of a blast furnace simulated by the discrete element method. Processes 8(1):6

Liu S, Zhou Z, Dong K, Yu A, Pinson D, Tsalapatis J (2015) Numerical investigation of burden distribution in a blast furnace. Steel Res Int 86(6):651–661

Yu Y, Saxén H (2013) Particle flow and behavior at bell-less charging of the blast furnace. Steel Res Int 84(10):1018–1033

Kou M, Xu J, Wu S, Zhou H, Gu K, Yao S, Wen B (2019) Effect of cross-section shape of rotating chute on particle movement and distribution at the throat of a bell-less top blast furnace. Particuology 44:194–206

Teng Z, Cheng S, Zhao G, Du P (2013) Effect of chute rotation on particles movement for bell-less top blast furnace. J Iron Steel Res Int 20(12):33–39

Mio H, Komatsuki S, Akashi M, Shimosaka A, Shirakawa Y, Hidaka J, Kadowaki M, Matsuzaki S, Kunitomo K (2009) Effect of chute angle on charging behavior of sintered ore particles at bell-less type charging system of blast furnace by discrete element method. ISIJ Int 49(4):479–486

Kou M, Wu S, Zhou H, Yu Y, Xu J (2018) Numerical investigation of coke collapse and size segregation in the bell-less top blast furnace. ISIJ Int 58(11):2018–2024

Hong Z, Zhou H, Wu J, Zhan L, Fan Y, Zhang Z, Wu S, Xu H, Wang L, Kou M (2021) Effects of operational parameters on particle movement and distribution at the top of a bell-less blast furnace based on discrete element method. Steel Res Int 92(1):2000262

Zhou K, Jiang Z, Pan D, Gui W, Huang J (2022) Influence of charging parameters on the burden flow velocity and distribution on the blast furnace chute based on discrete element method. Steel Res Int 93(1):2100332

Mitra T, Saxén H (2016) Discrete element simulation of charging and mixed layer formation in the ironmaking blast furnace. Comput Part Mech 3(4):541–555

Mio H, Narita Y, Matsuzaki S, Nishioka K, Nomura S (2019) Measurement of particle charging trajectory via rotating chute of 1/3-scale blast furnace and its comparing with numerical analysis using Discrete Element Method. Powder Technol 344:797–803

Zhou Z, Zhu H, Yu A, Wright B, Zulli P (2008) Discrete particle simulation of gas–solid flow in a blast furnace. Comput Chem Eng 32(8):1760–1772

Yu Y, Saxen H (2010) Experimental and DEM study of segregation of ternary size particles in a blast furnace top bunker model. Chem Eng Sci 65(18):5237–5250

Zhou Y, Wright B, Yang R, Xu B, Yu A (1999) Rolling friction in the dynamic simulation of sandpile formation. Phys A 269(2–4):536-553

Renzo Di, Di Maio F (2004) Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem Eng Sci 59(3):525–541

Yu Y, Saxén H (2012) Effect of DEM parameters on the simulated inter-particle percolation of pellets into coke during burden descent in the blast furnace. ISIJ Int 52(5):788–796

Yu Y, Saxén H (2014) Segregation behavior of particles in a top hopper of a blast furnace. Powder Technol 262:233–241

Xu W, Cheng S, Niu Q, Zhao G (2017) Effect of the main feeding belt position on burden distribution during the charging process of bell-less top blast furnace with two parallel hoppers. ISIJ Int 3:66

Xu W, Cheng S, Niu Q, Hu W, Bang J (2020) The DEM study of segregation phenomena of burden distribution during the charging process of blast furnace with two parallel hoppers. Ironmak Steelmak 47(4):337–343

Funding

This study was funded by the National Major Scientific Research Equipment of China (Grant No. 61927803), the National Natural Science Foundation of China Basic Science Center Project (Grant No. 61988101), the Science and Technology Innovation Program of Hunan Province (Grant No. 2021RC4054), the Hunan Provincial Innovation Foundation for Postgraduate (No. CX20200200), in part by the Fundamental Research Funds for the Central Universities of Central South University (Nos. 2020zzts124 and 2021 zzts0184).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, K., Jiang, Z., Pan, D. et al. Research on the velocity distribution law of the coke in the chute of blast furnace based on discrete element method. Comp. Part. Mech. 10, 303–311 (2023). https://doi.org/10.1007/s40571-022-00494-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-022-00494-6