Abstract

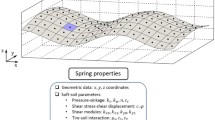

The traveling analysis of an off-road tire on granular terrain is a typical application of contact interaction problems between structures and granular particles. In previous studies, extensive efforts normally idealized irregular gravel materials using spherical discrete elements (DEs), and the influence of irregular shapes was ignored. In our recent works, a coupling algorithm that used a multi-sphere model to accurately represent irregular gravel particles in the context of tire-terrain interactions was proposed. However, this algorithm suffers from low computational efficiency for contact interactions. To address this issue, this work develops a robust and efficient contact algorithm to handle the complex interactions between multi-sphere DEs and finite element segments for tire traveling analysis. The advantages of the presented algorithm are three-folded. Firstly, a rectangular dynamic contact domain is reconstructed to reduce the computational cost in the global searching phase with the use of an efficient multi-grid algorithm. Secondly, we use virtual bounding spheres instead of virtual bounding boxes for hexahedral FE segments to reduce memory storage. Thirdly, a numerical treatment is developed to deal with multi-point contact problems between multi-sphere DEs and FE segments using an inside-outside algorithm in the local searching phase. Finally, the traveling behavior of two off-road tires on multi-sphere gravel terrain using our proposed algorithm is simulated, and the robustness, accuracy and efficiency of the presented algorithm is demonstrated via an indoor soil-bin data.

Similar content being viewed by others

References

Wong JY, McLaughlin NB, Knezevic Z, Burtt S (2016) Optimization of the tractive performance of four-wheel-drive tractors: theoretical analysis and experimental substantiation. Proc Inst Mech Eng Part D J Automob Eng 212:285–297. https://doi.org/10.1243/0954407981525966

Mohamed AMO (2003) Determination of in situ parameters of sandy soils for off-road vehicle mobility. J Terrramech 40:117–133. https://doi.org/10.1016/j.jterra.2003.10.002

Vantsevich VV (2007) Multi-wheel drive vehicle energy/fuel efficiency and traction performance: objective function analysis. J Terrramech 44:239–253. https://doi.org/10.1016/j.jterra.2007.03.003

Khot LR, Salokhe VM, Jayasuriya HPW, Nakashima H (2007) Experimental validation of distinct element simulation for dynamic wheel–soil interaction. J Terrramech 44:429–437. https://doi.org/10.1016/j.jterra.2007.12.002

Shinone H, Nakashima H, Takatsu Y, Kasetani T, Matsukawa H, Shimizu H, Miyasaka J, Ohdoi K (2010) Experimental analysis of tread pattern effects on tire tractive performance on sand using an indoor traction measurement system with forced-slip mechanism. Eng Agric Environ Food 3:61–66. https://doi.org/10.1016/s1881-8366(10)80020-5

Zeng H, Xu W, Zang M, Yang P (2019) Experimental and numerical investigations of tractive performance of off-road tires on gravel terrain. Int J Comput Methods. https://doi.org/10.1142/s0219876219500555

Hambleton JP, Drescher A (2009) Modeling wheel-induced rutting in soils: rolling. J Terrramech 46:35–47. https://doi.org/10.1016/j.jterra.2009.02.003

Michael M, Vogel F, Peters B (2015) DEM–FEM coupling simulations of the interactions between a tire tread and granular terrain. Comput Methods Appl Mech Eng 289:227–248. https://doi.org/10.1016/j.cma.2015.02.014

Nakashima H, Fujii H, Oida A, Momozu M, Kanamori H, Aoki S, Yokoyama T, Shimizu H, Miyasaka J, Ohdoi K (2010) Discrete element method analysis of single wheel performance for a small lunar rover on sloped terrain. J Terramech 47:307–321. https://doi.org/10.1016/j.jterra.2010.04.001

Smith W, Peng H (2013) Modeling of wheel–soil interaction over rough terrain using the discrete element method. J Terrramech 50:277–287. https://doi.org/10.1016/j.jterra.2013.09.002

Du Y, Gao J, Jiang L, Zhang Y (2017) Numerical analysis on tractive performance of off-road wheel steering on sand using discrete element method. J Terrramech 71:25–43. https://doi.org/10.1016/j.jterra.2017.02.001

Namjoo M (2012) Stress analysis of tractor tire interacting with soil using 2D finite element method. Int J Adv Des Manuf Technol, pp 107–111

Li H, Schindler C (2013) Investigation of tire-soil interaction with analytical and finite element method. Mech Based Des Struct Mach 41:293–315. https://doi.org/10.1080/15397734.2012.744677

Xia K, Yang Y (2012) Three-dimensional finite element modeling of tire/ground interaction. Int J Numer Anal Meth Geomech 36:498–516. https://doi.org/10.1002/nag.1018

Farhadi P, Golmohammadi A, Sharifi Malvajerdi A, Shahgholi G (2020) Tire and soil effects on power loss: measurement and comparison with finite element model results. J Terrramech 92:13–22. https://doi.org/10.1016/j.jterra.2020.09.004

Du Y, Gao J, Jiang L, Zhang Y (2016) Numerical analysis of lug effects on tractive performance of off-road wheel by DEM. J Braz Soc Mech Sci Eng 39:1977–1987. https://doi.org/10.1007/s40430-016-0633-4

Moslem N, Hossein G (2014) Numerical simulation of tire/soil interaction using a verified 3D finite element model. J Central South Univ 21:817–821. https://doi.org/10.1007/s11771-014-2005-5

Nakashima H, Takatsu Y, Shinone H, Matsukawa H, Kasetani T (2009) FE-DEM analysis of the effect of tread pattern on the tractive performance of tires operating on sand. J Mech Syst Transp Logist 2:55–65. https://doi.org/10.1299/jmtl.2.55

Nishiyama K, Nakashima H, Yoshida T, Ono T, Shimizu H, Miyasaka J, Ohdoi K (2016) 2D FE–DEM analysis of tractive performance of an elastic wheel for planetary rovers. J Terramech 64:23–35. https://doi.org/10.1016/j.jterra.2015.12.004

Nishiyama K, Nakashima H, Shimizu H, Miyasaka J, Ohdoi K (2017) 2D FE–DEM analysis of contact stress and tractive performance of a tire driven on dry sand. J Terramech 74:25–33. https://doi.org/10.1016/j.jterra.2017.09.003

Nakanishi R, Nakashima H, Miyasaka J, Ohdoi K (2020) Tractive performance analysis of a lugged wheel by open-source 3D DEM software. J Terramech 92:51–65. https://doi.org/10.1016/j.jterra.2020.10.001

Nishiyama K, Nakashima H, Yoshida T, Shimizu H, Miyasaka J, Ohdoi K (2018) FE-DEM with interchangeable modeling for off-road tire traction analysis. J Terramech 78:15–25. https://doi.org/10.1016/j.jterra.2018.03.005

Zhao C, Zang M (2014) Analysis of rigid tire traction performance on a sandy soil by 3D finite element–discrete element method. J Terrramech 55:29–37. https://doi.org/10.1016/j.jterra.2014.05.005

Zheng Z, Zang M, Chen S, Zhao C (2017) An improved 3D DEM-FEM contact detection algorithm for the interaction simulations between particles and structures. Powder Technol 305:308–322. https://doi.org/10.1016/j.powtec.2016.09.076

Horner DA, Peters JF, Carrillo A (2001) Large scale discrete element modeling of vehicle-soil interaction. J Eng Mech 127:1027–1032. https://doi.org/10.1061/(asce)0733-9399(2001)127:10(1027)

Yamashita H, Chen G, Ruan Y, Jayakumar P, Sugiyama H (2019) Hierarchical multiscale modeling of tire–soil interaction for off-road mobility simulation. J Comput Nonlinear Dyn 14:061007–061011. https://doi.org/10.1115/1.4042510

Recuero A, Serban R, Peterson B, Sugiyama H, Jayakumar P, Negrut D (2017) A high-fidelity approach for vehicle mobility simulation: nonlinear finite element tires operating on granular material. J Terrramech 72:39–54. https://doi.org/10.1016/j.jterra.2017.04.002

Yang P, Zang M, Zeng H (2019) DEM–FEM simulation of tire–sand interaction based on improved contact model. Comput Part Mech 7:629–643. https://doi.org/10.1007/s40571-019-00293-6

Zeng H, Xu W, Zang M, Yang P, Guo X (2020) Calibration and validation of DEM-FEM model parameters using upscaled particles based on physical experiments and simulations. Adv Powder Technol 31:3947–3959. https://doi.org/10.1016/j.apt.2020.06.044

Ai J, Chen J-F, Rotter JM, Ooi JY (2011) Assessment of rolling resistance models in discrete element simulations. Powder Technol 206:269–282. https://doi.org/10.1016/j.powtec.2010.09.030

Wensrich CM, Katterfeld A (2012) Rolling friction as a technique for modelling particle shape in DEM. Powder Technol 217:409–417. https://doi.org/10.1016/j.powtec.2011.10.057

Jiang M, Dai Y, Cui L, Xi B (2018) Experimental and DEM analyses on wheel-soil interaction. J Terrramech 76:15–28. https://doi.org/10.1016/j.jterra.2017.12.001

Yan Y, Ji S (2010) Discrete element modeling of direct shear tests for a granular material. Int J Numer Anal Methods Geomech 34:978–990. https://doi.org/10.1002/nag.848

Elmsahli HS, Sinka IC (2020) A discrete element study of the effect of particle shape on packing density of fine and cohesive powders. Comput Part Mech 8:183–200. https://doi.org/10.1007/s40571-020-00322-9

Khazeni A, Mansourpour Z (2018) Influence of non-spherical shape approximation on DEM simulation accuracy by multi-sphere method. Powder Technol 332:265–278. https://doi.org/10.1016/j.powtec.2018.03.030

Rakotonirina AD, Delenne J-Y, Radjai F, Wachs A (2018) Grains3D, a flexible DEM approach for particles of arbitrary convex shape—PArt III: extension to non-convex particles modelled as glued convex particles. Comput Part Mech 6:55–84. https://doi.org/10.1007/s40571-018-0198-3

Ma H, Zhao Y (2019) An approach to distribute the marker points on non-spherical particle/boundary surface within the IBM-LBM framework. Eng Anal Bound Elem 108:254–266. https://doi.org/10.1016/j.enganabound.2019.08.020

Govender N, Wilke DN, Pizette P, Abriak N-E (2018) A study of shape non-uniformity and poly-dispersity in hopper discharge of spherical and polyhedral particle systems using the Blaze-DEM GPU code. Appl Math Comput 319:318–336. https://doi.org/10.1016/j.amc.2017.03.037

Höhner D, Wirtz S, Scherer V (2012) A numerical study on the influence of particle shape on hopper discharge within the polyhedral and multi-sphere discrete element method. Powder Technol 226:16–28. https://doi.org/10.1016/j.powtec.2012.03.041

Kruggel-Emden H, Rickelt S, Wirtz S, Scherer V (2008) A study on the validity of the multi-sphere discrete element method. Powder Technol 188:153–165. https://doi.org/10.1016/j.powtec.2008.04.037

Lu G, Third JR, Müller CR (2012) Critical assessment of two approaches for evaluating contacts between super-quadric shaped particles in DEM simulations. Chem Eng Sci 78:226–235. https://doi.org/10.1016/j.ces.2012.05.041

Yan D, Yu J, Wang Y, Zhou L, Yu Y (2020) A general modelling method for soybean seeds based on the discrete element method. Powder Technol 372:212–226. https://doi.org/10.1016/j.powtec.2020.05.054

Favier JF, Abbaspour-Fard MH, Kremmer M, Raji AO (1999) Shape representation of axi-symmetrical, non-spherical particles in discrete element simulation using multi-element model particles. Eng Comput 16:467–480. https://doi.org/10.1108/02644409910271894

Zhao CL, Zang MY (2017) Application of the FEM/DEM and alternately moving road method to the simulation of tire-sand interactions. J Terrramech 72:27–38. https://doi.org/10.1016/j.jterra.2017.04.001

Munjiza A, Andrews KRF (1998) NBS contact detection algorithm for bodies of similar size. Int J Numer Methods Eng 43:131–149. https://doi.org/10.1002/(sici)1097-0207(19980915)43:1%3c131::Aid-nme447%3e3.0.Co

Williams JR, Perkins E, Cook B (2004) A contact algorithm for partitioning narbitrary sized objects. Eng Comput 21:235–248. https://doi.org/10.1108/02644400410519767

Chen H, Lei Z, Zang M (2014) LC-Grid: a linear global contact search algorithm for finite element analysis. Comput Mech 54:1285–1301. https://doi.org/10.1007/s00466-014-1058-5

Huang MXA (2010) HACell detection algorithm of particle discrete element for use in simulations of self-compacting concrete. J Tsinghua Univ 50(9):1357–1360

Wang F, Cheng J, Yao Z (2001) FFS contact searching algorithm for dynamic finite element analysis. Int J Numer Methods Eng 52:655–672. https://doi.org/10.1002/nme.221

Zhi-Hua Z, Nilsson L (1989) A contact searching algorithm for general contact problems. Comput Struct 33:197–209. https://doi.org/10.1016/0045-7949(89)90141-7

Yang P, Zang M, Zeng H (2020) An efficient 3D DEM-FEM contact detection algorithm for tire-sand interaction. Powder Technol 360:1102–1116. https://doi.org/10.1016/j.powtec.2019.10.069

Hallquist JO, Goudreau GL, Benson DJ (1985) Sliding interfaces with contact-impact in large-scale Lagrangian computations. Comput Methods Appl Mech Eng 51:107–137. https://doi.org/10.1016/0045-7825(85)90030-1

Belytschko T, Neal MO (1991) Contact-impact by the pinball algorithm with penalty and Lagrangian methods. Int J Numer Methods Eng 31:547–572. https://doi.org/10.1002/nme.1620310309

Su J, Gu Z, Xu XY (2011) Discrete element simulation of particle flow in arbitrarily complex geometries. Chem Eng Sci 66:6069–6088. https://doi.org/10.1016/j.ces.2011.08.025

Su J, Gu Z, Zhang M, Xu XY (2014) An improved version of RIGID for discrete element simulation of particle flows with arbitrarily complex geometries. Powder Technol 253:393–405. https://doi.org/10.1016/j.powtec.2013.12.009

Wang SP, Nakamachi E (1997) The inside-outside contact search algorithm for finite element analysis. Int J Numer Methods Eng 40:3665–3685. https://doi.org/10.1002/(sici)1097-0207

Hirota G, Fisher S, State A (2003) An improved finite-element contact model for anatomical simulations. Vis Comput 19:291–309. https://doi.org/10.1007/s00371-002-0188-5

Zhao C, Zang M, Chen S, Zheng Z (2018) Improving the 3D finite-discrete element method and its application in the simulation of wheel-sand interactions. Int J Comput Methods 15:1850059. https://doi.org/10.1142/s0219876218500597

Fang ZQ, Hu GM, Du J, Fan Z, Liu J (2015) A contact detection algorithm for multi-sphere particles by means of two-level-grid-searching in DEM simulations. Int J Numer Methods Eng 102:1869–1893. https://doi.org/10.1002/nme.4875

Huang P, Ding Y, Miao Q, Sang G, Jia M (2020) An improved contact detection algorithm for bonded particles based on multi-level grid and bounding box in DEM simulation. Powder Technol 374:577–596. https://doi.org/10.1016/j.powtec.2020.07.022

Zeng H, Xu W, Zang M, Yang P (2020) Calibration of DEM-FEM model parameters for traction performance analysis of an off-road tire on gravel terrain. Powder Technol 362:350–361. https://doi.org/10.1016/j.powtec.2019.12.006

Garcia X, Latham JP, Xiang J, Harrison JP (2009) A clustered overlapping sphere algorithm to represent real particles in discrete element modelling. Géotechnique 59:779–784. https://doi.org/10.1680/geot.8.T.037

Allen MPTD (1987) Computer simulation of liquids. Oxford Science Publications, Oxford

Džiugys A, Peters B (2001) An approach to simulate the motion of spherical and non-spherical fuel particles in combustion chambers. Granul Matter 3:231–266. https://doi.org/10.1007/pl00010918

Mio H, Shimosaka A, Shirakawa Y, Hidaka J (2005) Optimum cell size for contact detection in the algorithm of the discrete element method. J Chem Eng Jpn 38:969–975. https://doi.org/10.1252/jcej.38.969

Hallquist J (2007) LS-DYNA keyword user’s manual. Livermore Softw Technol Corp Calif 970:299–800

Roskilly SJ, Colbourn EA, Alli O, Williams D, Paul KA, Welfare EH, Trusty PA (2010) Investigating the effect of shape on particle segregation using a Monte Carlo simulation. Powder Technol 203:211–222. https://doi.org/10.1016/j.powtec.2010.05.011

Acknowledgements

This work was supported by the Science and Technology Planning Project of Guangzhou (No. 201804020065), the International Cooperation Project of the Ministry of Science and Technology of China (No. 2017YFE0117300), the National Natural Science Foundation of China (No. 11672344), and the Innovation Group Project of Southern Marine Science and Engineering Guangdong Laboratory (Zhuhai) (No.311021013).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Data structure

Appendix A: Data structure

In the global search algorithm, two 1D arrays MSDE_ID (k1) and FES1_ID (k2) are needed to store the ID information of the multi-sphere DE IDs and the hexahedral FE segments IDs, where k1 and k2 are the maximum numbers of the multi-sphere DEs and the FE segments in the rectangular dynamic contact region, respectively. For establishing the first layer grid, two 3D arrays are used to store the cell numbers of the bounding spheres of the multi-sphere DEs and FE segments, i.e., MSDE_CN (\(n_{{{\text{fir}},x}}\), \(n_{{{\text{fir}},y}}\), \(n_{{{\text{fir}},z}}\)) and FES_CN(\(n_{{{\text{fir}},x}}\), \(n_{{{\text{fir}},y}}\), \(n_{{{\text{fir}},z}}\)), where \(n_{{{\text{fir}},x}}\), \(n_{{{\text{fir}},y}}\) and \(n_{{{\text{fir}},z}}\) are the numbers of the cells in the x, y and z directions. In order to record the potential contact pairs between the bounding spheres of multi-sphere DEs or between the bounding spheres of multi-sphere DEs and the bounding spheres of FE segments, two 2D arrays (i.e., MSDE_PCP (K1, K3) and MSFE_PCP (K2, K4)) and two 1D arrays (TNM_MSDEPCP (K5) and TNM_MSFEPCP (K6)) are introduced, where K3 denotes the number of the potential contact pairs for the target bounding spheres of the multi-sphere DE K1, and K4 is the number for the target bounding sphere of the FE segment K2, respectively; K5 and K6 are, respectively, the total numbers of the potential contact pairs between multi-sphere DEs or between multi-sphere DEs and FE segments in the first layer grid.

Furthermore, two 2D arrays are also need to record ID information of the elemental spheres and the FE segments in the second layer grid, i.e., ES_ID (K1, K7) and FES2_ID (K2, K8), where K7 and K8 are the thresholds which are the maximum numbers of elemental spheres and FE segments in the local search domain. Since there is only one FE segment in the local coordinate system, the threshold of K8 in the array FES2_ID (K2, K8) is 1. For the contact detection between the elemental spheres of two multi-sphere DEs in the second layer grid, one 3D arrays ES_CN(\(n_{\sec ,x}\), \(n_{\sec ,y}\), \(n_{\sec ,z}\)) is extra required to store the cell numbers of the elemental spheres, where \(n_{\sec ,x}\), \(n_{\sec ,y}\) and \(n_{\sec ,z}\) are the numbers of the cells in the \(\alpha\), \(\beta\) and \(\chi\) directions, respectively. Finally, one 3D array ES_PCP (K1, K7, K9) is used to store the potential contact pairs between the elemental spheres of two multi-sphere DEs, where K9 is the total number of potential contact pairs in the second layer grid.

Rights and permissions

About this article

Cite this article

Guo, X., Zheng, Z., Chen, S. et al. An improved 3D multi-sphere DE-FE contact algorithm for interactions between an off-road pneumatic tire and irregular gravel terrain. Comp. Part. Mech. 10, 97–120 (2023). https://doi.org/10.1007/s40571-022-00479-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-022-00479-5