Abstract

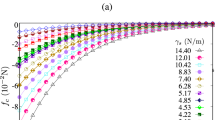

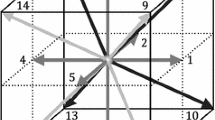

We study the erosion dynamics of wet particle agglomerates inside a simple shear flow of noncohesive granular materials by relying on the three-dimensional discrete-element simulations. The simulation model is discretized by assembling of wet and dry spherical particles. By systematically varying different parameters related to the shear flow of dry particles (the shear rate), the wet agglomerates (the amount of the binding liquid in the “pendular” state, the liquid viscosity, and the liquid–vapor surface tension), and the relative dry–wet density as well as the initial position of wet agglomerates, we measure the erosion of these agglomerates on their surface by quantifying the cumulative number of eroded particles. We show that the erosion rate increases proportionally to the inertial number and the height of the agglomerates decreases linearly with the liquid content and the liquid viscosity and decreases nonlinearly with the cohesion index (or liquid–vapor surface tension) for each value of the inertial number, whereas this rate is nearly independent to the relative dry–wet density with a low shear rate. It is worth noting that the normalized erosion rate by the shear rate collapses well on a master curve as a cutoff function of the erosion scaling parameter (combining the inertial number, the cohesion index, and the Stokes number), thus providing clear evidence for the unified description of the material and flow parameters on the erosion of wet agglomerates.

Similar content being viewed by others

References

Sastry KV, Dontula P, Hosten C (2003) Investigation of the layering mechanism of agglomerate growth during drum pelletization. Powder Technol 130(1):231–237

Aguado R, Roudier S, Delagado L (eds) (2013) Best available techniques (BAT) reference document for iron and steel production. Joint Research Centre of the European Commission, Luxembourg: Publications Office of the European Union

Walker GM (2007) Chapter 4 Drum granulation processes. In: Handbook of powder technology, Granulation, vol 11, pp 219–254

Rondet E, Delalonde M, Ruiz T, Desfoursb JP (2010) Fractal formation description of agglomeration in low shear mixer. Chem Eng J 164:376–382

Barkouti A, Rondet E, Delalonde M, Ruiz T (2012) Influence of physicochemical binder properties on agglomeration of wheat powder in couscous grain. J Food Eng 111:234–240

Nosrati A, Addai-Mensah J, Robinson DJ (2012) Drum agglomeration behavior of nickel laterite ore: effect of process variables. Hydrometallurgy 125–126:90–99

Iveson SM, Litster JD, Hapgood K, Ennis BJ (2001) Nucleation, growth and breakage phenomena in agitated wet granulation processes: a review. Powder Technol 117(1):3–39

Chien S H, Carmona G, Prochnow L I, Austin E R (2003) Cadmium availability from granulated and bulk-blended phosphate–potassium fertilizers. J Environ Qual 32(5):1911–1914

Suresh P, Sreedhar I, Vaidhiswaran R, Venugopal A (2017) A comprehensive review on process and engineering aspects of pharmaceutical wet granulation. Chem Eng J 328:785–815

Nimmo J (2005) Aggregation | physical aspects. In: Hillel D (ed) Encyclopedia of soils in the environment. Elsevier, Oxford, pp 28–35

Sarkar J, Dubey D (2016) Failure regimes of single wet granular aggregate under shear. J Non-Newton Fluid Mech 234:236–248

Lefebvre G, Jop P (2013) Erosion dynamics of a wet granular medium. Phys Rev E Stat Nonlinear Soft Matter Phys 8:032205

Vo T-Trung, Nezamabadi S, Mutabaruka P, Delenne J-Y, Izard E, Pellenq R, Radjai F (2019) Agglomeration of wet particles in dense granular flows. Eur Phys J E 42(9):127

Vo T-Trung, Mutabaruka P, Nezamabadi S, Delenne J-Y, Radjai F (2020) Evolution of wet agglomerates inside inertial shear flow of dry granular materials. Phys Rev E 101:032906

Taboada A, Estrada N, Radjaï F (2006) Additive decomposition of shear strength in cohesive granular media from grain-scale interactions. Phys Rev Lett 97(9):098302

Radjaï F, Richefeu V (2009) Bond anisotropy and cohesion of wet granular materials. Philos Trans R Soc A 367:5123–5138

Vo T-Trung, Mutabaruka P, Nezamabadi S, Delenne J-Y, Izard E, Pellenq R, Radjai F (2018) Mechanical strength of wet particle agglomerates. Mech Res Commun 92:1–7

Ennis BJ, Tardos G, Pfeffer R (1991) A microlevel-based characterization of granulation phenomena. Powder Technol 65(1):257–272

Talu I, Tardos GI, Khan MI (2000) Computer simulation of wet granulation. Powder Technol 110:59–75

Iveson S, Beathe J, Page N (2002) The dynamic strength of partially saturated powder compacts: the effect of liquid properties. Powder Technol 127:149–161

Saleh K, Guigon P (2007) Coating and encapsulation processes in powder technology. In: Handbook of powder technology, granulation, vol 11. Elsevier, Amsterdam, pp 323–375

Rahmanian N, Ghadiri M, Jia X (2009) Seeded granulation, powder technology 206(1) (2011) 53–62, 9th international symposium on agglomeration and 4th international granulation workshop

Ghadiri M, Salman AD, Hounslow M, Hassanpour A, York DW (2011) Editorial: Special issue—agglomeration. Chem Eng Res Des 89(5):499

Behjani M A, Rahmanian N, bt Abdul Ghani N F, Hassanpour A (2017) An investigation on process of seeded granulation in a continuous drum granulator using DEM. Adv Powder Technol 28(10):2456–2464

Radjai F, Topin V, Richefeu V, Voivret C, Delenne J-Y, Azéma E, El Youssoufi MS (2010) Force transmission in cohesive granular media. In: Goddard JD, Jenkins JT, Giovine P (eds) Mathematical modeling and physical instances of granular flows. AIP, College Park, pp 240–260

Bagnold RA (1954) Experiments on a gravity-free dispersion of large solid spheres in a Newtonian fluid under shear. Proc R Soc Lond 225:49–63

da Cruz F, Emam S, Prochnow M, Roux J-N, Chevoir F (2005) Rheophysics of dense granular materials: discrete simulation of plane shear flows. Phys Rev E 72:021309

Hassanpour A, Antony S, Ghadiri M (2006) Effect of size ratio on the behaviour of agglomerates embedded in a bed of particles subjected to shearing: DEM analysis. Chem Eng Sci 62:935–942

Hassanpour A, Antony SJ, Ghadiri M (2007) Modeling of agglomerate behavior under shear deformation: effect of velocity field of a high shear mixer granulator on the structure of agglomerates. Adv Powder Technol 18(6):803–811

GDR-MiDi (2004) On dense granular flows. Eur Phys J E 14:341–365

Jop P, Forterre Y, Pouliquen O (2006) A constitutive law for dense granular flows. Nature 441:727–730

Kamrin K, Koval G (2012) Nonlocal constitutive relation for steady granular flow. Phys Rev Lett 108:178301

Berger N, Azéma E, Douce J-F, Radjai F (2016) Scaling behaviour of cohesive granular flows. Europhys Lett 112:64004

Khamseh S, Roux J-N, Chevoir F (2015) Flow of wet granular materials: a numerical study. Phys Rev E 92:022201

Roy S, Luding S, Weinhart T (2017) A general(ized) local rheology for wet granular materials. New J Phys 19(4):043014

Badetti M, Fall A, Hautemayou D, Chevoir F, Aimedieu P, Rodts S, Roux J-N (2018) Rheology and microstructure of unsaturated wet granular materials: experiments and simulations. J Rheol 62(5):1175–1186

Badetti M, Fall A, Chevoir F, Roux J-N (2018) Shear strength of wet granular materials: macroscopic cohesion and effective stress. Eur Phys J E 41(5):68

Boyer F, Guazzelli E, Pouliquen O (2011) Unifying suspension and granular rheology. Phys Rev Lett 107:18

Trulsson M, Andreotti B, Claudin P (2012) Transition from the viscous to inertial regime in dense suspensions. Phys Rev Lett 109:118305

Amarsid L, Delenne J-Y, Mutabaruka P, Monerie Y, Perales F, Radjai F (2017) Viscoinertial regime of immersed granular flows. Phys Rev E 96:012901

Vo T-Trung, Nezamabadi S, Mutabaruka P, Delenne J-Y, Radjai F (2020) Additive rheology of complex granular flows. Nat Commun 11:1476

Pouliquen O, Cassar C, Jop P, Forterre Y, Nicolas M (2006) Flow of dense granular material: towards simple constitutive laws. J Stat Mech Theory Exp 2006:7020–7020

Forterre Y, Pouliquen O (2008) Flows of dense granular media. Ann Rev Fluid Mech 40(1):1–24

Vo T-T (2020) Rheology and granular texture of visco-inertial simple shear flows. J Rheol 64(5):1133–1145

Lian G, Thornton C, Adams MJ (1998) Discrete particle simulation of agglomerate impact coalescence. Chem Eng Sci 53(19):3381–3391

Štěpánek F, Rajniak P, Mancinelli C, Chern R, Ramachandran R (2009) Distribution and accessibility of binder in wet granules. Powder Technol 189(2):376–384

Richefeu V, Radjai F, Youssoufi MSE (2007) Stress transmission in wet granular materials. Eur Phys J E 21:359–369

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65

Herrmann HJ, Luding S (1998) Modeling granular media with the computer. Contin Mech Thermodyn 10:189–231

Thornton C (1999) Quasi-static shear deformation of a soft particle system. Powder Technol 109:179–191

Radjai F, Dubois F (2011) Discrete-element modeling of granular materials. Wiley-ISTE, London

Vo T-Trung, Mutabaruka P, Delenne J-Y, Nezamabadi S, Radjai F (2017) Strength of wet agglomerates of spherical particles: effects of friction and size distribution. EPJ Web Conf 140:08021

Luding S (1998) Collisions and contacts between two particles. In: Herrmann HJ, Hovi J-P, Luding S (eds) Physics of dry granular media—NATO ASI Series E350. Kluwer Academic Publishers, Dordrecht, p 285

Allen MP, Tildesley DJ (1987) Computer simulation of liquids. Oxford University Press, Oxford

Duran J, Reisinger A, de Gennes P (1999) Sands, powders, and grains: an introduction to the physics of granular materials, partially ordered systems. Springer, New York

Schäfer J, Dippel S, Wolf DE (1996) Force schemes in simulations of granular materials. J Phys I Fr 6:5–20

Dippel S, Batrouni GG, Wolf DE (1997) How transversal fluctuations affect the friction of a particle on a rough incline. Phys Rev E 56:3645–3656

Lian G, Thornton C, Adams M (1993) A theoretical study of the liquid bridge forces between two rigid spherical bodies. J Colloid Interface Sci 161:138–147

Scheel M, Seemann R, Brinkmann M, Michiel MD, Sheppard A, Herminghaus S (2008) Liquid distribution and cohesion in wet granular assemblies beyond the capillary bridge regime. J Phys Condens Matter 20(49):494236

Richefeu V, El Youssoufi M, Radjai F (2006) Shear strength properties of wet granular materials. Phys Rev E 73:051304

Delenne J-Y, Richefeu V, Radjai F (2015) Liquid clustering and capillary pressure in granular media. J Fluid Mech 762:R5

Than VD, Khamseh S, Tang AMA, Pereira J-M, Chevoir F, Roux J-N (2017) Basic mechanical properties of wet granular materials: a DEM study. J Eng Mech 143(1):C4016001

Mikami T, Kamiya H, Horio M (1998) Numerical simulation of cohesive powder behavior in a fluidized bed. Chem Eng Sci 53(10):1927–1940

Happel J, Brenner H (1983) Low Reynolds number hydrodynamics. Martinus Nijhoff Publishers, Leiden

Acknowledgements

The author gratefully acknowledges for useful discussions from (Franck) Farhang Radjai and Patrick Mutabaruka for his original supporting the code. MUSE Clusters at LMGC (University of Montpellier) are acknowledged for running some of the simulations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (avi 54222 KB)

Supplementary material 2 (avi 54220 KB)

Rights and permissions

About this article

Cite this article

Vo, TT. Erosion dynamics of wet particle agglomerates. Comp. Part. Mech. 8, 601–612 (2021). https://doi.org/10.1007/s40571-020-00357-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-020-00357-y