Abstract

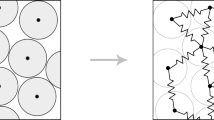

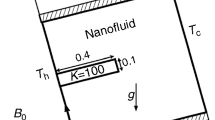

A hierarchical approach for modelling the thermal response of large-scale granular assemblies by coupling the micro-scale particle-level thermal interactions with the macro-scale continuum system is proposed. The coupling is done by using a machine learning tool that is trained to replicate the effect of discrete particle nature on the macro-scale system using finite elements. A trained Artificial Neural Network (ANN) tool that can estimate the effective local thermal conductivity for each finite element considering the influence of the presence of stagnant gas in the interstitial voids, gas pressure and the granular microstructure is used. This way of hierarchical coupling using ANN eliminates the need to perform thermal discrete element simulations for each finite element at every increment by directly predicting the effective local conductivity. The proposed hierarchical approach is applied to a breeder blanket of fusion reactor that consists of more than 15 million particles to demonstrate the efficacy of the method. The influence of the drop in gas pressure across the breeder unit and the heat generation on the temperature distribution of the full-scale breeder unit is analysed numerically.

Similar content being viewed by others

Notes

Note that the methodology can be applied even for an assembly with variable local packing fraction.

References

Cismondi F, Boccaccini LV, Aiello G, Aubert J, Bachmann C, Barrett T, Barucca L, Bubelis E, Ciattaglia S, Del Nevo A et al (2018) Progress in EU breeding blanket design and integration. Fusion Eng Des 136:782–792

Ying A, Reimann J, Boccaccini L, Enoeda M, Kamlah M, Knitter R, Gan Y, van der Laan JG, Magielsen L, Di Maio PA et al (2012) Status of ceramic breeder pebble bed thermo-mechanics R&D and impact on breeder material mechanical strength. Fusion Eng Des 87(7–8):1130–1137

Zhang D, Zhou J, Wu K, Li Z (2005) Granular phase changing composites for thermal energy storage. Sol Energy 78(3):471–480

Rady M (2009) Granular phase change materials for thermal energy storage: experiments and numerical simulations. Appl Thermal Eng 29(14–15):3149–3159

Abel J, Kornyshev AA, Lehnert W (1997) Correlated resistor network study of porous solid oxide fuel cell anodes. J Electrochem Soc 144(12):4253–4259

Singhal SC (2000) Advances in solid oxide fuel cell technology. Solid State Ion 135(1):305–313

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65

Herrmann HJ, Luding S (1998) Modeling granular media with the computer. Contin Mech Thermodyn 10(4):189–231

Kruggel-Emden H, Simsek E, Rickelt S, Wirtz S, Scherer V (2007) Review and extension of normal force models for the discrete element method. Powder Technol 171(3):157–173

Gan Y, Kamlah M (2010) Discrete element modelling of pebble beds: with application to uniaxial compression tests of ceramic breeder pebble beds. J Mech Phys Solids 58(2):129–144

Radjaï F, Dubois F (2011) Discrete-element modeling of granular materials. Wiley, Hoboken

Annabattula RK, Gan Y, Kamlah M (2012) Mechanics of binary and polydisperse spherical pebble assembly. Fusion Eng Des 87(5):853–858

Desu RK, Gan Y, Kamlah M, Annabattula RK (2016) Mechanics of binary crushable granular assembly through discrete element method. Nuclear Mater Energy 9:237–241

Siu WWM, Lee SH-K (2004) Transient temperature computation of spheres in three-dimensional random packings. Int J Heat Mass Transf 47(5):887–898

Kanuparthi S, Subbarayan G, Siegmund T, Sammakia B (2008) An efficient network model for determining the effective thermal conductivity of particulate thermal interface materials. IEEE Trans Compon Packag Technol 31(3):611–621

Yun TS, Evans TM (2010) Three-dimensional random network model for thermal conductivity in particulate materials. Comput Geotech 37:991–998

Moscardini M, Gan Y, Pupeschi S, Kamlah M (2018) Discrete element method for effective thermal conductivity of packed pebbles accounting for the Smoluchowski effect. Fusion Eng Des 127:192–201

Peeketi AR, Moscardini M, Vijayan A, Gan Y, Kamlah M, Annabattula RK (2018) Effective thermal conductivity of a compacted pebble bed in a stagnant gaseous environment: an analytical approach together with dem. Fusion Eng Des 130:80–88

Gan Y, Kamlah M (2007) Identification of material parameters of a thermo-mechanical model for pebble beds in fusion blankets. Fusion Eng Des 82(2):189–206

Duran J (2012) Sands, powders, and grains: an introduction to the physics of granular materials. Springer, Berlin

Radjai F, Roux JN, Daouadji A (2017) Modeling granular materials: century-long research across scales. J Eng Mech 143(4):04017002

Guo N, Zhao J (2014) A coupled fem/dem approach for hierarchical multiscale modelling of granular media. Int J Numer Methods Eng 99(11):789–818

Liu Y, Sun W, Yuan Z, Fish J (2016) A nonlocal multiscale discrete-continuum model for predicting mechanical behavior of granular materials. Int J Numer Methods Eng 106(2):129–160

Zehner P, Schlünder EU (1970) Wärmeleitfähigkeit von schüttungen bei mäßigen temperaturen. Chem Ing Tech 42(14):933–941

Zhou Zhao, Feng KM, Feng YJ (2010) Theoretical calculation and analysis modeling for the effective thermal conductivity of \(\text{ Li }_4\text{ SiO }_4\) pebble bed. Fusion Eng Des 85(10):1975–1980

Weidenfeld G, Weiss Y, Kalman H (2004) A theoretical model for effective thermal conductivity (ETC) of particulate beds under compression. Granul Matter 6(2–3):121–129

Gusarov AV, Kovalev EP (2009) Model of thermal conductivity in powder beds. Phys Rev B 80(2):024202

Desu RK, Peeketi AR, Annabattula RK (2019) Artificial neural network-based prediction of effective thermal conductivity of a granular bed in a gaseous environment. Comput Particle Mech 6(3):503–514

Pupeschi S, Knitter R, Kamlah M (2017) Effective thermal conductivity of advanced ceramic breeder pebble beds. Fusion Eng Des 116:73–80

Batchelor GK, O’Brien RW (1977) Thermal or electrical conduction through a granular material. In: Proceedings of the royal society of London. Series A, mathematical and physical sciences, pp 313–333

MATLAB (2010) version 7.10.0 (R2010a). The MathWorks Inc., Natick, Massachusetts

Reddy JN (2005) An introduction to the finite element method, 3rd edn. McGraw Hill Education (India) Private Limited, New Delhi

van der Laan JG, Reimann J, Fedorov AV (2016) Ceramic breeder materials. In: Reference module in materials science and materials engineering, Elsevier. https://doi.org/10.1016/B978-0-12-803581-8.00733-5

Cismondi F, Kecskés S, Ilic M, Légrádi G, Kiss B, Bitz O, Dolensky B, Neuberger H, Boccaccini LV, Ihli T (2009) Design update, thermal and fluid dynamic analyses of the EU-HCPB TBM in vertical arrangement. Fusion Eng Des 84(2–6):607–612

Abou-Sena A, Arbeiter F, Boccaccini LV, Schlindwein G (2014) Measurements of the purge helium pressure drop across pebble beds packed with lithium orthosilicate and glass pebbles. Fusion Eng Des 89(7–8):1459–1463

Pereslavtsev P, Lu L, Fischer U, Bitz O (2014) Neutronic analyses of the HCPB demo reactor using a consistent integral approach. Fusion Eng Des 89(9–10):1979–1983

Ergun S (1952) Fluid flow through packed columns. Chem Eng Prog 48:89–94

Löbbecke B, Knitter R, Rohde M, Reimann J (2009) Thermal conductivity of sintered lithium orthosilicate compacts. J Nuclear Mater 386:1068–1070

Liu YY, Tam SW (1985) Thermal conductivities for sintered and sphere-pac \(\text{ Li }_2\text{ O }\) and \(\gamma \)-\(\text{ LiAlO }_2\) solid breeders with and without irradiation effects. Fusion Sci Technol 7(3):399–410

Petersen H (1970) The properties of: density, specific heats, viscosity, and thermal conductivity at pressures from 1 to 100 bar and from room temperature to about 1800 k. In: Technical report. Risø National Laboratory, Roskilde. Forskningscenter Risoe. Risoe-R, No. 224

Lide DR (2012) CRC handbook of chemistry and physics. CRC Press, Boca Raton, p 12J204

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Peeketi, A.R., Desu, R.K., Kumbhar, P. et al. Thermal analysis of large granular assemblies using a hierarchical approach coupling the macro-scale finite element method and micro-scale discrete element method through artificial neural networks. Comp. Part. Mech. 6, 811–822 (2019). https://doi.org/10.1007/s40571-019-00265-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-019-00265-w