Abstract

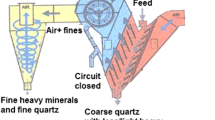

Manufactured sands are particulate materials obtained as by product of rock crushing. Particle sizes in the sand can be as high as 6 mm and as low as a few microns. The concrete industry has been increasingly using these sands as fine aggregates to replace natural sands. The main shortcoming is the excess of particles smaller than \(<0.075\) mm (Dust). This problem has been traditionally solved by a washing process. Air classification is being studied to replace the washing process and avoid the use of water. The complex classification process can only been understood with the aid of CFD–DEM simulations. This paper evaluates the applicability of a cross-flow air classifier to reduce the amount of dust in manufactured sands. Computational fluid dynamics (CFD) and discrete element modelling (DEM) were used for the assessment. Results show that the correct classification set up improves the size distribution of the raw materials. The cross-flow air classification is found to be influenced by the particle size distribution and the turbulence inside the chamber. The classifier can be re-designed to work at low inlet velocities to produce manufactured sand for the concrete industry.

Similar content being viewed by others

References

Aasly Aslaksen K, Danielsen S, Wigun J, Norman SH, Cepuritis R, Onnela T (2014) Review report on dry and wet classification of filler materials for concrete. COIN Project report 52 2014. www.coinweb.no

Alobaid F, Baraki N, Epple B (2014) Investigation into improving the efficiency and accuracy of CFD/DEM simulations. Particuology 16:41–53. doi:10.1016/j.partic.2013.11.004. http://www.sciencedirect.com/science/article/pii/S1674200113002289

Ansys software users documentation (2011) ANSYS FLUENT; Theory Guide, Release 14.0, ANSYS INC., United States, November 2011

Blazek J (2001) Computational fluid dynamics: principles and aplications, 1st edn. Elsevier, Amsterdam

Boemer D, Ponthot JP (2016) DEM modeling of ball mills with experimental validation: influence of contact parameters on charge motion and power draw. Comput Part Mech. doi:10.1007/s40571-016-0125-4

Cepuritis R, Jacobsen S, Onnela T (2015) Sand production with VSI crushing and air classification: Optimising fines grading for concrete production with micro-proportioning. Miner Eng 78:1–14. doi:10.1016/j.mineng.2015.03.025. http://www.sciencedirect.com/science/article/pii/S0892687515001156

Cho GC, Dodds J, Santamarina JC (2006) Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. J Geotech Geoenviron Eng 132(5):591–602

Chu K, Kuang S, Yu A, Vince A, Barnett G, Barnett P (2014) Prediction of wear and its effect on the multiphase flow and separation performance of dense medium cyclone. Miner Eng 56:91–101. doi:10.1016/j.mineng.2013.10.029. http://www.sciencedirect.com/science/article/pii/S0892687513003531

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Gotechnique 29(1):47–65. doi:10.1680/geot.1979.29.1.47

Elsayed K, Lacor C (2013) CFD modeling and multi-objective optimization of cyclone geometry using desirability function, artificial neural networks and genetic algorithms. Appl Math Model 37(8):5680–5704. doi:10.1016/j.apm.2012.11.010. http://www.sciencedirect.com/science/article/pii/S0307904X12007263

Esmaili A, Donohue T, Wheeler C, McBride W, Roberts A (2015) On the analysis of a coarse particle free falling material stream. Mineral processing in Australia and China (papers selected from the second Australia–China joint symposium on minerals and metallurgy) 142: 82–90. doi:10.1016/j.minpro.2015.02.013. http://www.sciencedirect.com/science/article/pii/S0301751615000733

Favier J, Abbaspour-Fard M, Kremmer M, Raji A (1999) Shape representation of axi-symmetrical, non-spherical particles in discrete element simulation using multi-element model particles. Eng Comput 16(4):467–480

Greifzu F, Kratzsch C, Forgber T, Lindner F, Schwarze R (2016) Assessment of particle-tracking models for dispersed particle-laden flows implemented in OpenFOAM and ANSYS FLUENT. Eng Appl Comput Fluid Mech 10(1):30–43. doi:10.1080/19942060.2015.1104266

Haider A, Levenspiel O (1989) Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol 58(1):63–70. doi:10.1016/0032-5910(89)80008-7. http://cdc338-www.sciencedirect.com/science/article/pii/0032591089800087

Johansson R, Evertsson M (2012) CFD simulation of a gravitational air classifier. Comput Model 33:20–26. doi:10.1016/j.mineng.2012.01.007. http://www.sciencedirect.com/science/article/pii/S089268751200009X

Johansson R, Evertsson M (2014) CFD simulation of a centrifugal air classifier used in the aggregate industry. Comput Model 63:149–156. doi:10.1016/j.mineng.2014.03.013. http://www.sciencedirect.com/science/article/pii/S089268751400082X

Klumpar IV, Currier FN, Ring TA (1986) Air classifiers. In: Cheremisinoff NP (ed) Encyclopedia of fluid mechanics: Solids and gas-solid flows, vol 4. pp 1361–1390

Lai WH, Lu WF, Chou MC (2009) Sorting of fine powder by gravitational classification chambers. Adv Powder Technol 20(2):177–184. doi:10.1016/j.apt.2008.08.003. http://www.sciencedirect.com/science/article/pii/S0921883108000265

Li H, Huang F, Cheng G, Xie Y, Tan Y, Li L, Yi Z (2016) Effect of granite dust on mechanical and some durability properties of manufactured sand concrete. Constr Build Mater 109:41–46. doi:10.1016/j.conbuildmat.2016.01.034. http://www.sciencedirect.com/science/article/pii/S0950061816300344

Li Y, Zhang X, Shen X, Li H, Gao K (2015) Experiment and simulation study on optimized structure of a gravitational air classifier. Int J Miner Process 141:44–50. doi:10.1016/j.minpro.2015.06.007. http://www.sciencedirect.com/science/article/pii/S0301751615001490

Mora C, Kwan A (2000) Sphericity, shape factor, and convexity measurement of coarse aggregate for concrete using digital image processing. Cem Concr Res 30(3):351–358. doi:10.1016/S0008-8846(99)00259-8. http://www.sciencedirect.com/science/article/pii/S0008884699002598

Morrow D (2011) Why manufactured sand? Metso’s customer magazine for the mining and construction industries: results minerals and aggregates 1:26–27

Morsi S, Alexander A (1972) An investigation of particle trajectories in two-phase flow systems. J Fluid Mech 55(02):193–208

Mundra S, Sindhi P, Chandwani V, Nagar R, Agrawal V (2016) Crushed rock sand an economical and ecological alternative to natural sand to optimize concrete mix. Recent Trends Eng Mater Sci 8:345–347. doi:10.1016/j.pisc.2016.04.070. http://www.sciencedirect.com/science/article/pii/S2213020916300921

Petit H, Barbosa M. Simulación de un clasificador de polvo de flujo cruzado con altos contenidos de polvo. Revista Internacional de Métodos Numéricos para Cálculo y Diseño en Ingeniería doi:10.1016/j.rimni.2016.06.003. http://www.sciencedirect.com/science/article/pii/S0213131516300268

Podlozhnyuk A, Pirker S, Kloss C (2017) Efficient implementation of superquadric particles in discrete element method within an open-source framework. Comput Part Mech 4(1):101–118. doi:10.1007/s40571-016-0131-6

Rolny D, Sovarso L, Cruz Palma J, Coyoupetrou L, Cremaschi G, Etcheverry R, Forte L (2015) Estudio Preliminar de la Forma, Textura Superficial y Distribución del Tamaño de Partículas de Arenas de trituración. In: Actas del Segundo Congreso Argentino de Aridos. San Isidro

Seville J, Wu C (2016) Particle technology adn engineering, 1st edn. Elsevier, Amsterdam

Shapiro M, Galperin V (2005) Air classification of solid particles: a review. Pneum Conveying Handl Part Solids 44(2):279–285. doi:10.1016/j.cep.2004.02.022. http://www.sciencedirect.com/science/article/pii/S0255270104000984

Shen W, Yang Z, Cao L, Cao L, Liu Y, Yang H, Lu Z, Bai J (2016) Characterization of manufactured sand: Particle shape, surface texture and behavior in concrete. Constr Build Mater 114:595–601. doi:10.1016/j.conbuildmat.2016.03.201. http://www.sciencedirect.com/science/article/pii/S0950061816305050

Shukla SK, Shukla P, Ghosh P(2011) Evaluation of numerical schemes using different simulation methods for the continuous phase modeling of cyclone separators. Special issue of the 6th World Congress on Particle Technology 22(2), 209–219. doi:10.1016/j.apt.2010.11.009. http://www.sciencedirect.com/science/article/pii/S0921883110002372

Singh S, Nagar R, Agrawal V, Rana A, Tiwari A (2016) Sustainable utilization of granite cutting waste in high strength concrete. J Clean Prod 116:223–235. doi:10.1016/j.jclepro.2015.12.110. http://www.sciencedirect.com/science/article/pii/S0959652616000032

Teng S, Wang P, Zhang Q, Gogos C (2011) Analysis of fluid energy mill by gas–solid two-phase flow simulation. Powder Technol 208(3):684–693. doi:10.1016/j.powtec.2010.12.033. http://www.sciencedirect.com/science/article/pii/S003259101100026X

Traoré P, Laurentie JC, Dascalescu L (2015) An efficient 4 way coupling CFD–DEM model for dense gassolid particulate flows simulations. Comput Fluids 113:65–76. doi:10.1016/j.compfluid.2014.07.017. http://www.sciencedirect.com/science/article/pii/S0045793014003028

Tu J, Yeoh GH, Liu C (2008) Computational fluid mechanics: a practical approach, 1st edn. Elsevier, Amsterdam

Versteeg HK, Malalasekera W (1995) An introduction to computational fluid dynamics: the finite volume method. Longman Scientific & Technical, London

Von Hafenbradl F, Da Silva S, Anja B (1997) The development of a cross-flow air classiffier. Postec Newsl 16:33–34

Wang Q, Melaaen MC, De Silva SR (2001) Investigation and simulation of a cross-flow air classifier. Powder Technol 120(3):273–280. doi:10.1016/S0032-5910(01)00282-0. http://www.sciencedirect.com/science/article/pii/S0032591001002820

Windows-Yule CRK, Tunuguntla DR, Parker DJ (2016) Numerical modelling of granular flows: a reality check. Comput Part Mech 3(3):311–332. doi:10.1007/s40571-015-0083-2

Winfield D, Cross M, Croft N, Paddison D, Craig I (2013) Performance comparison of a single and triple tangential inlet gas separation cyclone: a CFD Study. Powder Technol 235:520–531. doi:10.1016/j.powtec.2012.10.026. http://www.sciencedirect.com/science/article/pii/S0032591012007036

Yan Z, Wilkinson SK, Stitt EH, Marigo M (2015) Discrete element modelling (DEM) input parameters: understanding their impact on model predictions using statistical analysis. Comput Part Mech 2(3):283–299. doi:10.1007/s40571-015-0056-5

Zhong W, Yu A, Liu X, Tong Z, Zhang H (2016) DEM/CFD–DEM modelling of non-spherical particulate systems: theoretical developments and applications. Powder Technol 302:108–152. doi:10.1016/j.powtec.2016.07.010. http://www.sciencedirect.com/science/article/pii/S0032591016304065

Zhou F, Hu S, Liu Y, Liu C, Xia T (2014) CFD–DEM simulation of the pneumatic conveying of fine particles through a horizontal slit. Particuology 16:196–205. doi:10.1016/j.partic.2014.03.015. http://www.sciencedirect.com/science/article/pii/S1674200114000911

Acknowledgements

The authors express their gratitude for the support granted by the Consejo Nacional de Investigaciones Científicas y Técnicas (CONICET), Centro de Investigaciones en Física e Ingeniería del Centro de la Provincia de Buenos Aires (CIFICEN), Universidad Nacional del Centro de la Provincia de Buenos Aires (UNICEN) and Planta Piloto de Ingeniería Química (PLAPIQUI).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Petit, H.A., Irassar, E.F. & Barbosa, M.R. Evaluation of the performance of the cross-flow air classifier in manufactured sand processing via CFD–DEM simulations. Comp. Part. Mech. 5, 87–102 (2018). https://doi.org/10.1007/s40571-017-0155-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40571-017-0155-6