Abstract

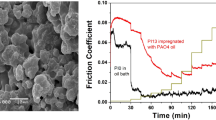

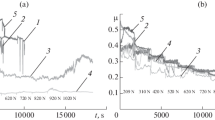

Herein, a porous oil-containing material with hierarchical pore structure was successfully prepared through microtexturing large pores on the surface of porous polyimide (PPI) with single-level small pores. Compared to the conventional oil-containing material, the hierarchically porous oil-containing material exhibited high oil-content, and retained excellent mechanical properties and high oil-retention because of the synergistic effects of large pores and small pores. Furthermore, the lubricant stored in the hierarchically porous polyimide could release to the interface under thermal-and-mechano-stimuli, and the released lubricant could be reabsorbed into the hierarchically porous polyimide via the capillary-force offered by the porous channel. Based on the high oil-content and recyclable oil release/reabsorption, the hierarchically porous oil-containing polyimide exhibited excellent lubrication performance (coefficient of friction was 0.057). Furthermore, the composite could perform 1,069 cycles of smart lubrication (1 h per cycle), which significantly extended the service life of the hierarchically porous oil-containing smart lubrication material.

Article PDF

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

References

Ruan H, Shao M, Zhang Y, Wang Q, Wang C, Wang T. Supramolecular oleogel-impregnated macroporous polyimide for high capacity of oil storage and recyclable smart lubrication. ACS Appl Mater Interfaces 14(8): 10936–10946 (2022)

Yu Q, Fan M, Li D, Song Z, Cai M, Zhou F, Liu W. Thermoreversible gel lubricants through universal supramolecular assembly of a nonionic surfactant in a variety of base lubricating liquids. ACS Appl Mater Interfaces 6(18): 15783–15794 (2014)

Kerni L, Raina A, Irfan MIU. Friction and wear performance of olive oil containing nanoparticles in boundary and mixed lubrication regimes. Wear 426–427: 819–827 (2019)

Tang J, Chen S, Jia Y, Ma Y, Xie H, Quan X, Ding Q. Carbon dots as an additive for improving performance in water-based lubricants for amorphous carbon (aC) coatings. Carbon 156: 272–281 (2020)

Kumari S, Chouhan A, Sharma P, Tawfik A, Tran K, Spencer J, Bhargava K, Walia S, Ray A, Khatri P. Surface functionalization of WS2 nanosheets with alkyl chains for enhancement of dispersion stability and tribological properties. ACS Appl Mater Interfaces 14(1): 1334–1346 (2021)

Singh N, Sinha K. Tribological performances of hybrid composites of Epoxy, UHMWPE and MoS2 with in situ liquid lubrication against steel and itself. Wear 486: 204072 (2021)

Vyavhare K, Timmons B, Erdemi A, Edwards L, Aswath B. Robust interfacial tribofilms by borate-and polymer-coated ZnO nanoparticles leading to improved wear protection under a boundary lubrication regime. Langmuir 37(5): 1743–1759 (2021)

Dong F, Hou G, Cao F, Yan F, Liu L, Wang J. The lubricity and reinforcement of carbon fibers in polyimide at high temperatures. Tribol Int 101: 291–300 (2016)

Li S, Duan C J, Li X, Shao M C, Qu C H, Zhang D, Wang Q H, Wang T M, Zhang X R. The effect of different layered materials on the tribological properties of PTFE composites. Friction 8(3): 542–552 (2020)

Duan C, Yuan D, Yang Z, Li S, Tao L, Wang Q, Wang T. High wear-resistant performance of thermosetting polyimide reinforced by graphitic carbon nitride (g-C3N4) under high temperature. Compos Part A: Appl Sci Manufac 113: 200–208 (2018)

Ragupathi K, Mani I. Durability and lube oil contamination study on diesel engine fueled with various alternative fuels: A review. Energy Sources, Part A 43(8): 932–943 (2018)

Gong H, Yu C, Zhang L, Xie G, Guo D, Luo J. Intelligent lubricating materials: A review. Compos Part B: Eng 202: 108450 (2020)

Zhang G, Xie G, Si L, Wen S, Guo D. Ultralow friction self-lubricating nanocomposites with mesoporous metal-organic frameworks as smart nanocontainers for lubricants. ACS Appl Mater Interfaces 9(43): 38146–38152 (2017)

Shao M, Li S, Duan C, Yang Z, Qu C, Zhang Y, Zhang D, Wang C, Wang T, Wang Q. Cobweb-like structural stimuli-responsive composite with oil warehouse and transportation system for oil storage and recyclable smart-lubrication. ACS Appl Mater Interfaces 10(48): 41699–41706 (2018)

Ruan H, Zhang Y, Li S, Yang L, Wang C, Wang T, Wang Q. Effect of temperature on the friction and wear performance of porous oil-containing polyimide. Tribol Int 157:106891 (2021)

Wang C, Zhang D, Wang Q, Ruan H, Wang T. Effect of porosity on the friction properties of porous polyimide impregnated with poly-α-olefin in different lubrication regimes. Tribol Lett 68(4): 1–9 (2020)

Ji Z, Xie G, Xu W, Wu S, Zhang L, Luo J. Self-cleaning of interfacial oil between polymer composites with porous zeolite microparticles and their self-lubrication properties. Adv Mater Interfaces 6(10): 1801889 (2019)

Gheisari R, Lan P, Polycarpou A. Efficacy of surface microtexturing in enhancing the tribological performance of polymeric surfaces under starved lubricated conditions. Wear 444–445: 203162 (2020)

Rosenkranz A, Costa L, Baykara Z, Martini A. Synergetic effects of surface texturing and solid lubricants to tailor friction and wear — A review. Tribol Int 155: 106792 (2021)

Ruan H, Zhang Y, Wang Q, Wang C, Wang T. A novel earthworm-inspired smart lubrication material with self-healing function. Tribol Int 165: 107303 (2022)

Zhang D, Wang C, Wang Q, Wang T. High thermal stability and wear resistance of porous thermosetting heterocyclic polyimide impregnated with silicone oil. Tribol Int 140: 105728 (2019)

Marchetti M, Meurisse M, Vergne P, Sicre J, Durand M. Analysis of oil supply phenomena by sintered porous reservoirs. Tribol Lett 10(3): 163–170 (2001)

Wang J, Zhao H, Huang W, Wang X. Investigation of porous polyimide lubricant retainers to improve the performance of rolling bearings under conditions of starved lubrication. Wear 380: 52–58 (2017)

Zhu Y, Wang G, Wang H, Zhang S, Yang S. Tribological properties of porous PPS/PTFE composite filled with mesopore titanium oxide whisker. J Appl Polym Sci 129(4): 2321–2327 (2013)

Wang H, Li M, Liu D, Zhao Y, Zhu Y. Tribological properties tests and simulations of the nano-micro multilevel porous self-lubricating PEEK composites with ionic liquid lubrication. J Mater Sci 51(8): 3917–3927 (2016)

Wang H, Wang G, Zhang S, Yang S, Zhu Y. Tribological performances on porous polyphenylene sulfide self-lubricating composites with super wear resistance. J Thermoplast Compos Mater 27(1): 82–92 (2014)

Yang X, Chen L, Li Y, Rooke C, Sanchez C, Su B. Hierarchically porous materials: synthesis strategies and structure design. Chem Soc Rev 46(2): 481–558 (2017)

Ding Y, Huang L, Barakat T, Su B. A novel 3DOM TiO2 based multifunctional photocatalytic and catalytic platform for energy regeneration and pollutants degradation. Adv Mater Interfaces 8(4): 2001879 (2021)

Sun M, Huang S, Chen L, Li Y, Yang X, Yuan Z, Su B. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine. Chem Soc Rev 45(12): 3479–3563 (2016)

Dorin M, Sai H, Wiesner U. Hierarchically porous materials from block copolymers. Chem Mater 26(1): 339–347 (2014)

Zhang D, Wang T, Wang Q, Wang C. Selectively enhanced oil retention of porous polyimide bearing materials by direct chemical modification. J Appl Polym Sci 134(29): 45106 (2017)

Kaufmann J, Loser R, Leemann A. Analysis of cement-bonded materials by multi-cycle mercury intrusion and nitrogen sorption. J Colloid Interface Sci 336(2): 730–737 (2009)

Su B, Huang L, Huang W, Wang X. The load carrying capacity of textured sliding bearings with elastic deformation. Tribol Int 109: 86–96 (2017)

Acknowledgements

This research was financially supported by the National Key R&D Program of China (2020YFB2006901), National Natural Science Foundation of China (51935006), CAS Project for Young Scientists in Basic Research (YSBR-023), Youth Innovation Promotion Association of Chinese Academy of Sciences (Grant No. 2020417), and Key Research Program of the Chinese Academy of Sciences (XDPB24).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Tingmei WANG. She is currently a researcher and doctoral supervisor at Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, China. She received her bachelor degree (1992) in Department of Organic Chemical Engineering, Northwest University and Ph.D. degree (2003) in Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences. Her current research interests focus on design and preparation of porous polymer composites, design and development of polymer composites, preparation and properties of organic/inorganic nanocomposites, and development of high strength fiber reinforced composites. She has published over 200 journal papers and gained a number of awards.

Chao WANG. He is currently a researcher and doctoral supervisor at Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, China. He received his Ph.D. degree in Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences. His current research interests focus on design and preparation of porous polymer composites, and design and development of smart lubrication material and polymer self-lubricating composites. He is a candidate for the talent project of “Light of West China” Program of Chinese Academy of Sciences, and Youth Innovation Promotion Association of Chinese Academy of Sciences.

Hongwei RUAN. He is a Ph.D. candidate in the Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, University of Chinese Academy of Sciences. His research focuses on the porous oil-containing material and the development of smart lubrication material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ruan, H., Zhang, Y., Song, F. et al. Efficacy of hierarchical pore structure in enhancing the tribological and recyclable smart lubrication performance of porous polyimide. Friction 11, 1014–1026 (2023). https://doi.org/10.1007/s40544-022-0642-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-022-0642-5