Abstract

Friction modifiers (FMs) are surface-active additives added to base fluids to reduce friction between rubbing surfaces. Their effectiveness depends on their interactions with rubbing surfaces and may be mitigated by the choice of the base fluid. In this work, the performance of an imidazolium ionic liquid (ImIL) additive in polyethylene-glycol (PEG) and 1,4-butanediol for lubricating steel/steel and diamond-like-carbon/diamond-like carbon (DLC—DLC) contacts were investigated. ImIL-containing PEG reduces friction more effectively in steel—steel than DLC—DLC contacts. In contrast, adding ImIL in 1,4-butanediol results in an increase in friction in steel—steel contacts. Results from the Raman spectroscopy, X-ray photoelectron spectroscopy (XPS), and focused ion beam-transmission electron microscopy (FIB-TEM) reveal that a surface film is formed on steel during rubbing in ImIL-containing PEG. This film consists of two layers. The top layer is composed of amorphous carbon and are easily removed during rubbing. The bottom layer, which contains iron oxide and nitride compound, adheres strongly on the steel surface. This film maintains its effectiveness in a steel—steel contact even after ImIL additives are depleted. Such film is not observed in 1,4-butanediol where the adsorption of ImIL is hindered, as suggested by the quartz crystal microbalance (QCM) measurements. No benefit is observed when the base fluid on its own is sufficiently lubricious, as in the case of DLC surfaces.

This work provides fundamental insights on how compatibilities among base fluid, FM, and rubbing surface affect the performance of IL as surface active additives. It reveals the structure of an ionic liquid (IL) surface film, which is effective and durable. The knowledge is useful for guiding future IL additive development.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Bronshteyn L A, Kreiner J H. Energy efficiency of industrial oils. Tribol Trans 42(4): 771–776 (1999)

Hsu S M, Zhang J, Yin Z F. The nature and origin of tribochemistry. Tribol Lett 13(2): 131–139 (2002)

Boyde S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem 4(4): 293–307 (2002)

Spikes H. Friction modifier additives. Tribol Lett 60: 5 (2015)

Zhang J, Meng Y G. Boundary lubrication by adsorption film. Friction 3(2): 115–147 (2015)

Mordukhovich G, Qu J, Howe J Y, Bair S, Yu B, Luo H M, Smolenski D J, Blau P J, Bunting B G, Dai S. A low-viscosity ionic liquid demonstrating superior lubricating performance from mixed to boundary lubrication. Wear 301(1–2): 740–746 (2013)

Desanker M, He X L, Lu J, Liu P Z, Pickens D B, Delferro M, Marks T J, Chung Y W, Wang Q J. Alkyl-cyclens as effective sulfur- and phosphorus-free friction modifiers for boundary lubrication. ACS Appl Mater Interfaces 9(10): 9118–9125 (2017)

Bassanetti I, Twist C P, Kim M G, Seyam A M, Bazzi H S, Wang Q J, Chung Y W, Marchió L, Delferro M, Marks T J. Synthesis and characterization of silver(I) pyrazolylmethylpyridine complexes and their implementation as metallic silver thin film precursors. Inorg Chem 53(9): 4629–4638 (2014)

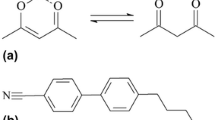

Li K, Amann T, List M, Walter M, Moseler M, Kailer A, Rühe J. Ultralow friction of steel surfaces using a 1,3-diketone lubricant in the thin film lubrication regime. Langmuir 31(40): 11033–11039 (2015)

Zhou Y, Qu J. Ionic liquids as lubricant additives: A review. ACS Appl Mater Interfaces 9(4): 3209–3222 (2017)

Zhou F, Liang Y M, Liu W M. Ionic liquid lubricants: Designed chemistry for engineering applications. Chem Soc Rev 38(9): 2590–2599.

Qu J, Luo H M, Chi M F, Ma C, Blau P J, Dai S, Viola M B. Comparison of an oil-miscible ionic liquid and ZDDP as a lubricant anti-wear additive. Tribol Int 71: 88–97 (2014)

Zhou Y, Weber J, Viola M B, Qu J. Is more always better? Tribofilm evolution and tribological behavior impacted by the concentration of ZDDP, ionic liquid, and ZDDP-ionic liquid combination. Wear 432-433: 202951 (2019)

Yu Q L, Zhang C Y, Dong R, Shi Y J, Wang Y R, Bai Y Y, Zhang J Y, Cai M R, Zhou F, Liu W M. Physicochemical and tribological properties of gemini-type halogen-free dicationic ionic liquids. Friction 9(2): 344–355 (2021)

Qu M H, Yang Z Q, Zhang C Y, Yu Q L, Cai M R, Zhou F. Significantly enhancing lubricity and anti-wear performances of glycerol lubricant with urea-functionalized imidazolium-organophosphate ionic liquid as additive. Tribol Int 153: 106602 (2021)

Cai M R, Yu Q L, Liu W M, Zhou F. Ionic liquid lubricants: When chemistry meets tribology. Chem Soc Rev 49(21): 7753–7818 (2020)

Li W M, Kumara C, Luo H M, Meyer H M III, He X, Ngo D, Kim S H, Qu J. Ultralow boundary lubrication friction by three-way synergistic interactions among ionic liquid, friction modifier, and dispersant. ACS Appl Mater Interfaces 12(14): 17077–17090 (2020)

Li W M, Kumara C, Meyer H M III, Luo H M, Qu J. Compatibility between various ionic liquids and an organic friction modifier as lubricant additives. Langmuir 34(36): 10711–10720 (2018)

Guegan J, Southby M, Spikes H. Friction modifier additives, synergies and antagonisms. Tribol Lett 67(3): 83 (2019)

Ngo D, He X, Luo H M, Qu J, Kim S H. Competitive adsorption of ionic liquids versus friction modifier and anti-wear additive at solid/lubricant interface—Speciation with vibrational dum frequency generation spectroscopy. Lubricants 8(11): 98 (2020)

Neville A, Morina A, Haque T, Voong M. Compatibility between tribological surfaces and lubricant additives—How friction and wear reduction can be controlled by surface/lube synergies. Tribol Int 40(10–12): 1680–1695 (2007)

Hanna F F, Gestblom B, Soliman A. Dielectric relaxation study of alcohol/diol(s) mixtures. J Mol Liq 95(1): 27–40 (2002)

Fujimori Y, Kaden W E, Brown M A, Cuenya B R, Sterrer M, Freund H J. Hydrogen evolution from metal—surface hydroxyl interaction. J Phys Chem C 118(31): 17717–17723 (2014)

Grill A. Review of the tribology of diamond-like carbon. Wear 168(1–2): 143–153 (1993)

Dou Q Y, Liu L Y, Yang B J, Lang J W, Yan X B. Silica-grafted ionic liquids for revealing the respective charging behaviors of cations and anions in supercapacitors. Nat Commun 8: 2188 (2017)

Viesca J L, Battez A H, González R, Reddyhoff T, Pérez A T, Spikes H A. Assessing boundary film formation of lubricant additivised with 1-hexyl-3-methylimidazolium tetrafluoroborate using ECR as qualitative indicator. Wear 269(1–2): 112–117 (2010)

Hamrock B J, Dowson D. Isothermal elastohydrodynamic lubrication of point contacts: Part III—Fully flooded results. J Lubr Technol 99(2): 264–275 (1977)

Tavakkoli M, Panuganti S R, Vargas F M, Taghikhani V, Pishvaie M R, Chapman W G. Asphaltene deposition in different depositing environments: Part 1. Model oil. Energy Fuels 28(3): 1617–1628 (2014)

Campen S, Smith B, Wong J. Deposition of asphaltene from destabilized dispersions in heptane—toluene. Energy Fuels 32(9): 9159–9171 (2018)

Quraishi M A, Nayak D K, Kumar R, Kumar V. Corrosion of reinforced steel in concrete and its control: An overview. J Steel Struct Constr 3(1): 1000124. (2017)

Wu H X, Khan A M, Johnson B, Sasikumar K, Chung Y W, Wang Q J. Formation and nature of carbon-containing tribofilms. ACS Appl Mater Interfaces 11(17): 16139–16146 (2019)

De Faria D L A, Venâncio Silva S, de Oliveira M T. Raman microspectroscopy of some iron oxides and oxyhydroxides. J Raman Spectrosc 28(11): 873–878 (1997)

Hanesch M. Raman spectroscopy of iron oxides and (oxy)hydroxides at low laser power and possible applications in environmental magnetic studies. Geophys J Int 177(3): 941–948 (2009)

Berman D, Erdemir A, Sumant A V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 59: 167–175 (2013)

Berman D, Erdemir A, Sumant A V. Few layer graphene to reduce wear and friction on sliding steel surfaces. Carbon 54: 454–459 (2013)

Totolin V, Göcerler H, Rodríguez Ripoll M, Jech M. The role of ferric oxide nanoparticles in improving lubricity and tribo-electrochemical performance during chemical—mechanical polishing. Tribol Lett 65(1): 20 (2017)

Han Y Y, Qiao D, Guo Y X, Feng D P, Shi L. Influence of competitive adsorption on lubricating property of phosphonate ionic liquid additives in PEG. Tribol Lett 64(2): 22 (2016)

Iida S, Hidaka Y. Influence of the iron oxide layer on lubricating properties in seamless pipe hot rolling. Tetsu-to-Hagane 94(7): 244–250 (2008)

Hu Z S, Dong J X, Chen G X. Study on antiwear and reducing friction additive of nanometer ferric oxide. Tribol Int 31(7): 355–360 (1998)

Fiaschi G, Rota A, Ballestrazzi A, Marchetto D, Vezzalini E, Valeri S. A chemical, mechanical, and tribological analysis of DLC coatings deposited by magnetron sputtering. Lubricants 7(4): 38 (2019)

Ge X Y, Li J J, Zhang C H, Liu Y H, Luo J B. Superlubricity and antiwear properties of in situ-formed ionic liquids at ceramic interfaces induced by tribochemical reactions. ACS Appl Mater Interfaces 11(6): 6568–6574 (2019)

Xu Y F, Peng Y B, Dearn K D, Zheng X J, Yao L L, Hu X G. Synergistic lubricating behaviors of graphene and MoS2 dispersed in esterified bio-oil for steel/steel contact. Wear 342-343: 297–309 (2015)

Wu B N, Breen J P, Xing X Y, Fayer M D. Controlling the dynamics of ionic liquid thin films via multilayer surface functionalization. J Am Chem Soc 142(20): 9482–9492 (2020)

Zhou Y, Dyck J, Graham T W, Luo H M, Leonard D N, Qu J. Ionic liquids composed of phosphonium cations and organophosphate, carboxylate, and sulfonate anions as lubricant antiwear additives. Langmuir 30(44): 13301–13311 (2014)

Dong R, Yu Q L, Bai Y Y, Wu Y, Ma Z F, Zhang J Y, Zhang C Y, Yu B, Zhou F, Liu W M, et al. Towards superior lubricity and anticorrosion performances of proton-type ionic liquids additives for water-based lubricating fluids. Chem Eng J 383: 123201 (2020)

Lukevics E, Dzintara M. The alcoholysis of hydrosilanes. J Organomet Chem 295(3): 265–315 (1985)

Oostendorp D J, Bertrand G L, Stoffer J O. Kinetics and mechanism of the hydrolysis and alcoholysis of alkoxysilanes. J Adhesion Sci Technol 6(1): 171–191 (1992)

Khan T, Koide S, Tamura Y, Yamamoto H, Morina A, Neville A. Effects of using alternative extreme pressure (EP) and anti-wear (AW) additives with oxy-nitrided samples. Tribol Lett 66(1): 43 (2018)

Zhao J, Mao J Y, Li Y R, He Y Y, Luo J B. Friction-induced nano-structural evolution of graphene as a lubrication additive. Appl Surf Sci 434: 21–27 (2018)

Taylor G I. The mechanism of plastic deformation of crystals. Part I.—Theoretical. Proc Roy Soc A Mat Phys Eng Sci 145(855): 362–387 (1934)

Anderson J S, Tilley R J D. Crystallographic shear in oxygen-deficient rutile: An electron microscope study. J Solid State Chem 2(3): 472–482 (1970)

Zhang J, Spikes H. On the mechanism of ZDDP antiwear film formation. Tribol Lett 63(2): 24 (2016)

Gosvami N N, Bares J A, Mangolini F, Konicek A R, Yablon D G, Carpick R W. Mechanisms of antiwear tribofilm growth revealed in situ by single-asperity sliding contacts. Science 348(6230): 102–106 (2015)

Guo Y X, Zhang L G, Zhang G, Wang D A, Wang T M, Wang Q H. High lubricity and electrical responsiveness of solvent-free ionic SiO2 nanofluids. J Mater Chem A 6(6): 2817–2827 (2018)

Acknowledgements

Wei SONG is supported by China Scholarship Council. The authors would like to thank Dr. Gwilherm KERHERVE of the Advanced Photoelectron Spectroscopy Laboratory, Imperial College London, for his help with XPS. The authors would also like to acknowledge the support from Imperial College Research Computing Service (DOI: 10.14469/hpc/2232).

Author information

Authors and Affiliations

Corresponding author

Additional information

Declaration of competing interest

The authors have no competing interests to declare that are relevant to the content of this article.

Wei SONG. He received his Ph.D. degree in chemistry in 2021 from Sun Yat-sen University, China. He was a visiting Ph.D. student in Tribology Group in Imperial College London, UK, from November 2019 to October 2021. He recently joined the State Key Laboratory of Tribology in Tsinghua University, China, as a postdoctor. His research interest includes friction modifier (FM) under boundary lubrication.

Jie ZHANG. He received his M.S. degree in tribology and surface engineering from China University of Geosciences (Beijing), China, in 2007. He subsequently joined the Tribology Group in Imperial College London, UK, as a Ph.D. student and completed in 2011. Since 2013, he started to work in the same group as a research associate on different projects. His main research areas cover boundary lubrication, wear, lubricant additives, elasto-hydrodynamic (EHD) lubrication, micro-electro-mechanical system (MEMS), zinc dialkyldithiophosphate (ZDDP), mechanochemistry, and atmospheric tribology.

Sophie CAMPEN. She received her M.S. degree in chemistry and her Ph.D. degree in mechanical engineering from Imperial College London, UK, in 2007 and 2012, respectively. Her current position is the research associate at the University of Cambridge, UK. Her research areas include boundary lubrication, mechanochemistry, and surface adsorption.

Jincan YAN. He received his bachelor’s degree in chemistry and master’s degree in organic chemistry from Huaibei Normal University, China, in 2002 and 2008, respectively, and Ph.D. degree in mechanical engineering from Twente University, the Netherlands, and Ph.D. degree in chemical engineering from Shanghai JiaoTong University, China, in 2014. He is now an associate professor in Shanghai Institute of Technology, China. His research interests include lubricant additives, lubricating oil and grease, cutting fluid, and surface engineering.

Hongbing JI. He received his bachelor’s degree and Ph.D. degree in chemical engineering from South China University of Technology, China, in 1992 and 1997, respectively. His current position is a professor in Sun Yat-sen University, China. His research areas cover biomimetic catalysis, heterogeneous catalysis, homogeneous catalysis, and lubricant additives.

Janet S.S. WONG. She received her Ph.D. degree from University of Illinois at Urbana-Champaign, USA, in 2008. She is now a senior lecturer in the Tribology group, Mechanical Engineering Department, Imperial College London, UK. Her research interest covers phenomena at solid—liquid interface, lubricant rheology, additive technology, mechanochemistry, and in-situ experimentation development.

Electronic Supplementary Material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Song, W., Zhang, J., Campen, S. et al. Lubrication mechanism of a strong tribofilm by imidazolium ionic liquid. Friction 11, 425–440 (2023). https://doi.org/10.1007/s40544-022-0614-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-022-0614-9