Abstract

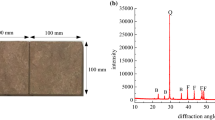

The sliding friction of rock, involving all kinds of particles at the contact surface, is relevant to many problems, ranging from those in artificial engineering to earthquake dynamics. In this work, the frictional performance of the shale rock–dry quartz sand contact was investigated using a self-developed testing device. The study showed that the coefficient of friction of the contact increases with nominal stress and that the corresponding friction force increases approximately linearly with nominal stress, which is directly related to the contact stress between each single sand particle and rock shale. An overall dynamic coefficient, γ, reflecting the response of friction force to nominal stress, first decreases and then increases with area ratio, which is determined by not only the contact stress but also the interparticle friction force. These have important repercussions for a preliminary understanding of the frictional properties of the shale rock–dry quartz sand contact in hydraulic fracturing and related industrial applications.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Fall A, Weber B, Pakpour M, Lenoir N, Shahidzadeh N, Fiscina J, Wagner C, Bonn D. Sliding friction on wet and dry sand. Phys Rev Lett 112(17): 175502 (2014)

Xiao H P, Liu S H, Wang D G. Tribological properties of sliding shale rock–alumina contact in hydraulic fracturing. Tribol Lett 62(2): 20 (2016)

Zhang S W. Green tribology: Fundamentals and future development. Friction 1(2): 186–194 (2013)

Beste U, Lundvall A, Jacobson S. Micro-scratch evaluation of rock types—a means to comprehend rock drill wear. Tribol Int 37(2): 203–210 (2004)

Yang H Q, Wang H, Zhou X P. Analysis on the rock–cutter interaction mechanism during the TBM tunneling process. Rock Mech Rock Eng 49(3): 1073–1090 (2016)

Dougherty P S M, Mpagazehe J, Shelton J, Higgs III C F. Elucidating PDC rock cutting behavior in dry and aqueous conditions using tribometry. J Petrol Sci Eng 133: 529–542 (2015)

Goldsby D L, Tullis T E. Low frictional strength of quartz rocks at subseismic slip rates. Geophys Res Lett 29(17): 25–1–25–4 (2002)

Goldsby D L, Tullis T E. Flash heating leads to low frictional strength of crustal rocks at earthquake slip rates. Science 334(6053): 216–218 (2011)

Chen X F. Rock friction and dynamic faulting at the micro-to nano-scales. Ph.D Thesis. Norman (USA): University of Oklahoma, 2015.

Tullis T E. Rock friction and its implications for earthquake prediction examined via models of Parkfield earthquakes. Proc Natl Acad Sci USA 93(9): 3803–3810 (1996)

Di Toro G, Goldsby D L, Tullis T E. Friction falls towards zero in quartz rock as slip velocity approaches seismic rates. Nature 427(6973): 436–439 (2004)

Di Toro G, Hirose T, Nielsen S, Pennacchioni G, Shimamoto T. Natural and experimental evidence of melt lubrication of faults during earthquakes. Science 311(5761): 647–649 (2006)

Reches Z, Lockner D A. Fault weakening and earthquake instability by powder lubrication. Nature 467(7314): 452–455 (2010)

Stachowiak G W. How tribology has been helping us to advance and to survive. Friction 5(3): 233–247 (2017)

Storti F, Billi A, Salvini F. Particle size distributions in natural carbonate fault rocks: Insights for non-self-similar cataclasis. Earth Planet Sci Lett 206(1–2): 173–186 (2003)

Morgan J K. Numerical simulations of granular shear zones using the distinct element method: 2. Effects of particle size distribution and interparticle friction on mechanical behavior. J Geophys Res: Solid Earth 104(B2): 2721–2732 (1999)

Wang T, Zhou W B, Chen J H, et al. Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int J Coal Geol 121: 1–13 (2014)

Barati R, Liang J T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J Appl Polym Sci 131(16): 40735 (2014)

Holmberg K, Erdemir A. Influence of tribology on global energy consumption, costs and emissions. Friction 5(3): 263–284 (2017)

Dougherty P S M, Pudjoprawoto R, Higgs III C F. Bit cutter-on-rock tribometry: Analyzing friction and rate-ofpenetration for deep well drilling substrates. Tribol Int 77: 178–185 (2014)

Hsu S, Ying C, Zhao F. The nature of friction: A critical assessment. Friction 2(1): 1–26 (2014)

Akrad O M, Miskimins J L, Prasad M. The effects of fracturing fluids on shale rock mechanical properties and proppant embedment. In SPE Annual Technical Conference and Exhibition, Denver, Colorado, USA, 2011.

Dutta A K, Penumadu D. Hardness and modulus of individual sand particles using nanoindentation. In Geo-Denver 2007 Congress: New Peaks in Geotechnics, Denver, CO, 2007: 1–10.

Wang Q J, Zhu D. Hertz theory: Contact of spherical surfaces. In Encyclopedia of Tribology. Wang Q J, Chuang Y W, Eds. Boston, MA: Springer, 2013: 1654–1662.

Acknowledgment

Support by National Natural Science Foundation of China (No. 51575529) is acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Huijie ZHANG. She received her bachelor degree in mechanical engineering and automation in 2015 from China University of Petroleum–Beijing, China. After then, she was PhD student in mechanical engineering at the same university. Her research interests include water-based lubrication and wear mechanism.

Shuhai LIU. He received his PhD degree in mechanical engineering in 2009 from Tsinghua University, Beijing, China. He joined the College of Mechanical and Transportation Engineering at China University of Petroleum–Beijing from 2009. His current position is a Professor and the Assistant Dean of the College. His research interests include tribology, surface science, and petroleum science.

Huaping XIAO. He received his bachelor degree in 2006 from Tianjin University, Tianjin, China and master degree in 2011 from Tsinghua University, Beijing, China. He has earned PhD degree in mechanical engineering in 2014 from Texas A&M University (TAMU), USA. He joined the College of Mechanical and Transportation Engineering at China University of Petroleum from 2014. His current position is an Associate Professor. His research areas include tribology properties and wear behaviors under complicated work condition and bio-related tribological systems.

Rights and permissions

Open Access The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Zhang, H., Liu, S. & Xiao, H. Sliding friction of shale rock on dry quartz sand particles. Friction 7, 307–315 (2019). https://doi.org/10.1007/s40544-018-0213-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-018-0213-y