Abstract

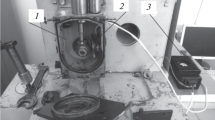

This paper reports a test investigation of friction and wear responses from sand contaminated lubricated sliding. The influence of sand contaminants on wear and friction is characterized. Analyses are completed utilizing segments of piston ring sliding against the cylinder liner. Paraffin oil, with and without sand contaminants, is utilized. The effects of the concentration and particle size of sand are examined.

Based on the observations in the present work, we found that friction and wear increase with sand concentration in the lube. Solid proposals ought to be considered, in order to enlighten the general population on the importance of changing a car engine’s oil filter regularly.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Sari M R, Ville F, Haiahem A, Flamand L. Effect of lubricant contamination on friction and wear in An EHL sliding contact. Mechanika 2(82): 43–49 (2010)

Aldi N, Morini M, Pinelli M, Spina P R, Suman A. An interdisciplinary approach to study the fouling phenomenon. Energy Procedia 82: 280–285 (2015)

Ebert F J. Fundamentals of design and technology of rolling element bearings. Chin J Aeronaut 23(1): 123–136 (2010)

Maru M M, Tanaka D K. Influence of loading, contamination and additive on the wear of a metallic pair under rotating and reciprocating lubricated sliding. J Braz Soc Mech Sci Eng 28(3): 278–285 (2006)

Maru M M, Tanaka D K. Oil contamination and additive effects on the wear and friction of metallic specimens in reciprocating lubricated sliding tests. In Proceedings of the 17th International Congress of Mechanical Engineering, São Paulo, Brazil, 2013.

Sheikh A M, Khashaba M I, Ali W Y. Reducing the mechanical wear in a dusty environment (Cement Factory). Int J Eng Technol IJET-IJENS 11(6): 138–144 (2011)

Mousa M O, Ali W Y. Particle size effect on friction and wear caused by abrasive contaminants in lubricating oil. In Proceedings of the 3rd Int Ain-Shams Univ Conf on Prod Eng & Des for Development, 1990: 27–29.

Ali W Y, Mousa M O. Wear and friction of cylindrical contacts by lubricant abrasive contaminants. In The EGTRIB First Tribology Conference, Cairo, Egypt, 1989: 20–21.

Ali W Y, Fodor J, Westcott V C. The effect of abrasive contamination on journal bearing performance. In The ASME/ASLE Tribology Conference, Westtin William Penn, Pittsburg, 1986: 20–22.

Alrawadeh M, Aldajah S. Tribological characterization of the sand particles concentration on sliding lubricated contact. Int J Adv Technol Eng Sci 3(5): 2348–7550 (2015)

Rabinowicz E. Friction and Wear of Materials. New York, NY (USA): Wiley, 1965.

Bhushan B. Introduction to Tribology. New York, NY (USA): Wiley, 2002.

Rabinowicz E. Friction and Wear of Materials. 2nd ed. New York, NY (USA): Wiley, 1995.

Khruschov M M. Principles of abrasive wear. Wear 28(1): 69–88 (1974)

Yunus S, Rashid A A, Latip S A, Abdullah N R, Ahmad M A, Abdullah A H. Comparative study of used and unused engine oil (Perodua Genuine and Castrol Magnatec Oil) based on property analysis basis. Procedia Eng 68: 326–330 (2013)

La Rocca A, Bonatesta F, Fay M W, Campanella F. Characterisation of soot in oil from a gasoline direct injection engine using transmission electron microscopy. Tribol Int 86: 77–84 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Mohamed Ahmed RAMADAN. He received his PhD degree in mechanical engineering from El-Minia University, Egypt, in 2010. His current position is an assistant professor at Faculty of Engineering at Helwan, Helwan University, Egypt. His research areas cover the tribology and mechanical design, material science, and tribology of biomaterials.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made.

The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

To view a copy of this licence, visit https://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ramadan, M.A. Friction and wear of sand-contaminated lubricated sliding. Friction 6, 457–463 (2018). https://doi.org/10.1007/s40544-017-0192-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-017-0192-4