Abstract

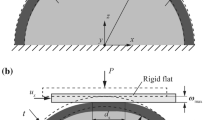

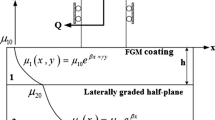

A finite element analysis is used to study the elastic-plastic contact of a coated sphere compressed by a rigid flat under the stick contact condition. This was done for a wide range of hard coating material properties and coating thicknesses. A comparison with the slip contact condition is presented in terms of the critical contact parameters (at yield inception) and plasticity evolution. Empirical expressions are provided for critical interferences of the first and second yield inceptions, in the coating and on the substrate side of the interface, respectively. An expression is also provided for the dimensionless coating thickness for optimal resistance to plasticity under the stick contact condition. Additionally, the relations between different contact parameters in the elastic-plastic regime are presented. In general, it was found that the contact condition has a negligible effect on the contact parameters, except for phenomena occurring close to the contact area.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Treutler C P O. Industrial use of plasma-deposited coatings for components of automotive fuel injection systems. Surface and Coatings Technology 200: 1969–1975 (2005)

Scharf T W, Prasad S V, Dugger M T, Kotula P G, Goeke R S, Grubbs R K. Growth, structure, and tribological behavior of atomic layer-deposited tungsten disulphide solid lubricant coatings with applications to MEMS. Acta Materialia 54: 4731–4743 (2006)

Law H H, Holden C A, Sapjeta J, Crane G R, Nakahara S. Electrical contact phenomena of nickel electrodeposits with sharp micro-asperities. Transactions on Components Hybrids and Manufacturing Technology 14: 585–591 (1991)

Neubauer E, Korb G, Eisenmenger-Sittner C, Bangert H, Chotikaprakhan S, Dietzel D, Mansanares A M, Bein B K. The influence of mechanical adhesion of copper coatings on carbon surfaces on the interfacial thermal contact resistance. Thin Solid Films 433: 160–165 (2003)

Clarke D R. Materials selection guidelines for low thermal conductivity thermal barrier coatings. Surface and Coatings Technology 163: 67–74 (2003)

Piazza F, Grambole D, Schneider D, Casiraghi C, Ferrari A C, Robertson J. Protective diamond-like carbon coatings for future optical storage disks. Diamond and Related Materials 14: 994–999 (2005)

Schintlmeister W, Wallgram W, Kanz J, Gigl K. Cutting tool materials coated by chemical vapor deposition. Wear 100: 153–169 (1984)

Greenwood J, Williamson J. Contact of nominally flat surfaces. The Royal Society (London) 295: 300–319 (1966)

Chang W, Etsion I, Bogy D B. An elastic-plastic model for the contact of rough surfaces. ASME Journal of Tribology 109: 257–263 (1987)

Jackson R L, Kogut L. A comparison of flattening and indentation approaches for contact mechanics modeling of single asperity contacts. Tribology Transactions 128: 209–212 (2006)

Komvopoulos K. Finite element analysis of a layered elastic solid in normal contact with a rigid surface. ASME Journal of Tribology 110: 477–485 (1988)

Kral E, Komvopoulos K, Bogy D. Finite element analysis of repeated indentation of an elastic-plastic layered medium by a rigid sphere, Part II: Subsurface results. Journal of Applied Mechanics 62: 29–42 (1995)

Ronkainen H, Koskinen J, Varjus S, Holmberg K. Loadcarrying capacity evaluation of coating/substrate systems for hydrogen-free and hydrogenated diamond-like carbon films. Tribology Letters 6: 63–73 (1999)

Ye N, Komvopoulos K. Indentation analysis of elastic-plastic homogeneous and layered media: criteria for determining the real material hardness. ASME Journal of Tribology 125: 685–691 (2003)

Botelho T D S, Progri R, Inglebert G, Robbe-Valloire F. Analytical and experimental elastoplastic spherical indentations of a layered half-space. Mechanics of Materials 40: 771–779 (2008)

Ahmadi S R, Shakeri M, Sadough A. Stress analysis in thin coatings and substrate subjected to point contact loading (mechanics of scratch test). Journal of Materials Processing Technology 205: 89–98 (2008)

Kulchytsky-Zhyhailo R, Rogowski G. Stresses in hard coating due to a rigid spherical indenter on a layered elastic half-space. Tribology International 43: 1592–1601 (2010)

Johnson K L. Contact Mechanics 1 st ed. Cambridge: Cambridge University Press, 1985.

Kogut L, Etsion I. Elastic-plastic contact analysis of a sphere and a rigid flat. Journal of Applied Mechanics 69: 657–662 (2002)

Goodman L E. Contact stress analysis of normally loaded rough spheres. Journal of Applied Mechanics 29: 515–522 (1962)

Spence D A. The Hertz contact problem with finite friction. Journal of Elasticity 5(3–4): 297–319 (1975)

Brizmer V, Kligerman Y, Etsion I. The effect of contact conditions and material properties on the elasticity terminus of a spherical contact. International Journal of Solids and Structures 43: 5736–5749 (2006)

Brizmer V, Zait Y, Kligerman Y, Etsion I. The effect of contact conditions and material properties on elastic-plastic spherical contact. Journal of Mechanics of Material and Structures 1(5): 865–879 (2006)

Overcharenko A, Hlperin G, Verberne G, Etsion I. In situ investigation of the contact area in elastic-plastic spherical contact during loading-unloading. Tribology Letters 25(2): 153–160 (2007)

Goltsberg R, Etsion I, Davidi G. The onset of plastic yielding in a coated sphere compressed by a rigid flat. Wear 271: 2968–2977 (2011)

Song W, Li L, Ovcharenko A, Jia D, Etsion I, Talke F E. Plastic yield inception of an indented coated flat and comparison with a flattened coated sphere. Tribology International 52: 61–67 (2012)

Huang X, Kasem H, Shang H F, Shao T M, Etsion I. Experimental study of a potential weakening effect in spheres with thin hard coatings. Wear 296: 590–597 (2012)

Goltsberg R, Etsion I. A model for the weakening effect of very thin hard coatings. Wear 308: 10–16 (2013)

Goltsberg R, Etsion I. A universal model for the load–displacement relation in an elastic coated spherical contact. Wear 322: 126–132 (2015)

Goltsberg R, Etsion I. Contact area and maximum equivalent stress in elastic spherical contact with hard coating. Tribology International 93: 289–296 (2016)

Sun Y, Bloyce A, Bell T. Finite element analysis of plastic deformation of various TiN coating/substrate systems under normal contact with a rigid sphere. Thin Solid Films 271: 122–131 (1995)

Kral E, Komvopoulos K, Bogy D. Finite element analysis of repeated indentation of an elastic-plastic layered medium by a rigid sphere, Part II: Subsurface results. Journal of Applied Mechanics 62: 29–42 (1995)

Yoo Y-H, Lee W, Shin H. Spherical nano-indentation of a hard thin film/soft substrate layered system: II. Evolution of stress and strain fields. Modeling and Simulation in Materials Science and Engineering 12: 69–78 (2004)

Chen Z, Goltsberg R, Etsion I. Plasticity evolution in a coated sphere compressed by a rigid flat. Tribology International 98: 116–124 (2016)

Acknowledgment

This paper is part of IEA AMT IA technical activities.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Shai RONEN. He received his bachelor degree in mechanical engineering in 2010 from Technion-Israel Institute of Technology. Recently he had obtained his master degree in design and manufacturing management from the same institute.

Roman GOLTSBERG. He received his bachelor degree in mechanical engineering in 2010 from Technion-Israel Institute of Technology. In 2015 he had obtained his Ph.D. degree in mechanical engineering from the same institute. His research interests include contact mechanics of coatings and hydrodynamic bearings.

Izhak ETSION. He received his PhD degree in 1974 from Technion-Israel Institute of Technology. Since then he was a faculty at the Department of Mechanical Engineering where he is currently a Professor Emeritus. His research interests are in hydrodynamic lubrication, surface texturing, contact mechanics, nano-tribology and bio-tribology. Etsion has published over 200 papers on various aspects of tribology and holds 15 patents. He is the founder of Surface Technologies Ltd. that developed the laser surface texturing (LST) technology for friction and wear reduction. His honors include Fellow of the ASME (1999), Fellow of the STLE (2001), the STLE 2005 International Award and the ASME 2016 Mayo D. Hersey Award.

Rights and permissions

Open Access : The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Ronen, S., Goltsberg, R. & Etsion, I. A comparison of stick and slip contact conditions for a coated sphere compressed by a rigid flat. Friction 5, 326–338 (2017). https://doi.org/10.1007/s40544-017-0178-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-017-0178-2