Abstract

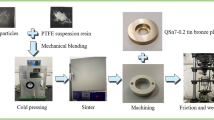

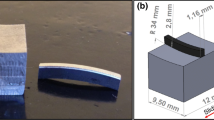

Polyether-ether-ketone (PEEK) and polyimide (PI) are two kinds of engineering polymer materials widely used as roller bearing cages and rings under extreme environment because of their noise reduction and corrosion resistance properties. The Si3N4 ceramic is the most common ball bearing material. Many current engineering applications of ball bearings require aqueous lubrication. Therefore, this study presents the aqueous lubrication of tribopairs formed by PEEK and PI material sliding against Si3N4 ceramic. Experimental results show that two tribopairs exhibited the similar tribological properties under the dry condition. Water as a lubricant for the PI–Si3N4 tribopair pairs effectively reduces both friction coefficients by 35.5% and wear rates by 32%. The water absorption of PI induces better tribological properties by changing the tribopair surface properties. In addition, the dimples appearing on the PI tribopair surface under water generate additional hydrodynamic lubrication and further improve the friction properties of surface. The PEEK–Si3N4 tribopair shows similar friction coefficients under two kinds of environments. The wear rates under water are approximately more than two times of that under dry sliding. However, water inhibits the appearance of the crush phenomenon and enhances the carrying capacity of the tribopair. Energy dispersive spectroscopy and X-ray diffraction spectra demonstrate no chemical corrosion. The 3D profiler and SEM morphologies illustrate that the transfer film would be formed from the surface of PEEK under water but hindered under dry friction. Overall, the PI–Si3N4 tribopair exhibits better properties than PEEK under water and is promising for future applications in the bearing industry.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Cong P H, Li T S, Xue Q J. Friction and wear of Polyimide and composite materials. Lubrication Engineering (04): 2–7 (1998)

Cai H, Yan F Y, Chen J M, Xue Q J. Review on the Modification of Polyimide. Journal of Materials Science and Engineering 1: 026 (2003)

Hammouti S, Beaugiraud B, Salvia M, Mauclair C, Pascale-Hamri A, Benayoun S, Valette S. Elaboration of submicron structures on PEEK polymer by femtosecond laser. Applied Surface Science 327: 277–287 (2015)

Czichos H, Klaffke D, Santner E, Woydt M. Advances in tribology: the materials point of view. Wear 190(2): 155–161 (1995)

Michaljanicová I, Slepicka P, Rimpelová S, Slepicková Kasálková N, Švorcík V. Regular pattern formation on surface of aromatic polymers and its cytocompatibility. Applied Surface Science 370: 131–141 (2016)

Hammouti S, Pascale-Hamri A, Faure N, Beaugiraud B, Guibert M, Mauclair C, Benayoun S, Valette S. Wear rate control of peek surfaces modified by femtosecond laser. Applied Surface Science 357: 1541–1551 (2015)

Mizobe K, Honda T, Koike H, Santos E C, Kashima Y, Kida K. Effect of PTFE retainer on friction coefficient in polymer thrust bearings under dry contact. Advanced Materials Research 683: 90–93 (2013)

Koike H, Mizobe K, Oyama S, Kashima Y, Kanemasu K, Kida K. Observation of wear on PEEK-PTFE hybrid radial bearings. Advanced Materials Research 683: 385–390 (2013)

Zhang Z, Breidt C, Chang L, Friedrich K. Wear of PEEK composites related to their mechanical performances. Tribology International 37(3): 271–277 (2004)

Aurélie D, Huong H T, Ahmad F, Aurore L, Guy L, Jalal B, Aissam A, Emmanuel A, Jean-François C. Improving adhesion of powder coating on PEEK composite: Influence of atmospheric plasma parameters. Applied Surface Science 357: 1196–1204 (2015)

Samyn P, Schoukens G, De Baets P. Micro-to nanoscale surface morphology and friction response of tribological polyimide surfaces. Applied Surface Science 256(11): 3394–3408 (2010)

Sun C, Zhou F, Shi L, Yu B, Gao P, Zhang J, Liu W. Tribological properties of chemically bonded polyimide films on silicon with polyglycidyl methacrylate brush as adhesive layer. Applied Surface Science 253(4): 1729–1735 (2006)

Zalaznik M, Kalin M, Novak S. Influence of the processing temperature on the tribological and mechanical properties of poly-ether-ether-ketone (PEEK) polymer. Tribology International 94: 92–97 (2016)

Koike H, Kida K, Mizobe K, Shi X, Oyama S, Kashima Y. Wear of hybrid radial bearings (PEEK ring-PTFE retainer and alumina balls) under dry rolling contact. Tribology International 90: 77–83 (2015)

Greco A C, Erck R, Ajayi O, Fenske G. Effect of reinforcement morphology on high-speed sliding friction and wear of PEEK polymers. Wear 271(9): 2222–2229 (2011)

Theiler G, Gradt T. Friction and wear of PEEK composites in vacuum environment. Wear 269(3): 278–284 (2010)

Guo X D, Dai Y, Gong M, Qu Y G, Helseth L E. Changes in wetting and contact charge transfer by femtosecond laser-ablation of polyimide. Applied Surface Science 349: 952–956 (2015)

Liu B, Pei X, Wang Q, Sun X, Wang T. Effects of proton and electron irradiation on the structural and tribological properties of MoS2/polyimide. Applied Surface Science 258(3): 1097–1102 (2011)

Samyn P, Schoukens G. The effect of processing method on dry sliding performance of polyimides at high load/high velocity conditions. European Polymer Journal 44(3): 716–732 (2008)

Jia J H, Zhou H D, Gao S Q, Chen J M. A comparative investigation of the friction and wear behavior of polyimide composites under dry sliding and water-lubricated condition. Materials Science and Engineering: A 356 (1–2): 48–53 (2003)

Riveiro A, Soto R, Comesana R, Boutinguiza M, del Val J, Quintero F, Lusquiños F, Pou J. Laser surface modification of PEEK. Applied Surface Science 258(23): 9437–9442 (2012)

Aurélie D, Huong H T, Ahmad F, Aurore L, Guy L, Jalal B, Aissam A, Emmanuel A, Jean-François C. Improving adhesion of powder coating on PEEK composite: Influence of atmospheric plasma parameters. Applied Surface Science 357: 1196–1204 (2015)

Tavenner E, Wood B, Curry M, Jankovic A, Patel R. Graphitic structure formation in ion implanted polyetheretherketone. Applied Surface Science 283: 154–159 (2013)

Laurens P, Sadras B, Decobert F, Arefi F, Amouroux J. Modifications of polyether-etherketone surface after 193 nm and 248 nm excimer laser radiation. Applied Surface Science 138: 93–96 (1999)

Feng Y, Gottmann J, Kreutz E W. Structuring of poly ether ether ketone by ArF excimer laser radiation in different atmospheres. Applied Surface Science 211(1): 68–75 (2003)

Almasi D, Izman S, Assadian M, Ghanbari M, Abdul Kadir M R. Crystalline ha coating on peek via chemical deposition. Applied Surface Science 314: 1034–1040 (2014)

Mackova A, Malinsky P, Miksova R, Khaibullin R I, Valeev V F, Svorcik V, Slepicka P, Slouf M. The characterization of PEEK, PET and PI implanted with Co ions to high fluences. Applied Surface Science 275: 311–315 (2013)

Faruque Ahmed S, Lee K R, Yoon J I, Moon M W. Nanoporous structures of polyimide induced by Ar ion beam irradiation. Applied Surface Science 258(8): 3841–3845 (2012)

Sun C, Zhou F, Shi L, Yu B, Gao P, Zhang J, Liu W. Tribological properties of chemically bonded polyimide films on silicon with polyglycidyl methacrylate brush as adhesive layer. Applied Surface Science 253(4): 1729–1735 (2006)

Ran J, Zhang J, Yao W, Wei Y. Properties of Cu film and Ti/Cu film on polyimide prepared by ion beam techniques. Applied Surface Science 256(23): 7010–7017 (2010)

Yang D, Dong Y, Gong J. The Tribological Behaviors of PEEK Filled PTFE Composites. Lubrication Engineering 38(10): 60–63 (2013)

Wang X. Investigation of tribological performance and simulation of temperature field during sliding contact for polyimide composites. Master Thesis. Nanjing Industrial University, 2005.

Huang L J, Yang C C, Wang X D, Huang P. Tribological properties of polyimide composites against different metal under dry sliding friction condition. Materials for Mechanical Engineering 10: 016 (2009)

Wang X D, Wang X, Zhu P, Huang P. Mechanical properties and tribological performance of plastic. Materials for Mechanical Engineering 11: 013 (2005)

Samyn P, Schoukens G, Verpoort F, Van Craenenbroeck J, De Baets P. Friction and wear mechanisms of sintered and thermoplastic polyimides under adhesive sliding. Macromolecular Materials and Engineering 292(5): 523–556 (2007)

Dong W, Nie S, Zhang A. Tribological behavior of PEEK filled with CF/PTFE/graphite sliding against stainless steel surface under water lubrication. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 227(10): 1129–1137 (2013)

Zhang Z, Nie S, Yuan S, Liao W. Comparative Evaluation of Tribological Characteristics of CF/PEEK and CF/ PTFE/Graphite Filled PEEK Sliding against AISI630 Steel for Seawater Hydraulic Piston Pumps/Motors. Tribology Transactions 58(6): 1096–1104 (2015)

Chen B, Wang J, Yan F. Friction and wear behaviors of several polymers sliding against GCr15 and 316 steel under the lubrication of sea water. Tribology Letters 42(1): 17–25 (2011)

Wu D, Liu Y, Yang S, Yang Z, Tang H. Friction and wear characteristics of WC–10Co–4Cr/Si3N4 tribopair lubricated under silt-laden water. Wear 294: 370–379 (2011)

Shi Y, Minami I, Grahn M, Björling M, Larsson R. Boundary and elastohydrodynamic lubrication studies of glycerol aqueous solutions as green lubricants. Tribol Int 69: 39–45 (2014)

Chen B, Wang J, Yan F. Microstructure of PTFE-based polymer blends and their tribological behaviors under aqueous environment. Tribology Letters 45(3): 387–395 (2012)

Guan X, Wang L. The tribological performances of multilayer graphite-like carbon (GLC) coatings sliding against polymers for mechanical seals in water environments. Tribology Letters 47(1): 67–78 (2012)

Liu H, Wang T, Wang Q. Tribological Properties of Thermosetting Polyimide/TiO2 Nanocomposites Under Dry Sliding and Water-Lubricated Conditions. Journal of Macromolecular Science, Part B 51(11): 2284–2296 (2012)

Zhao H, Zhang J, Ji T, Yang M, Chao M, Kou K. Investigation of tribological properties of PI/FEP laminated composites under dry sliding, water-and oil-lubricated conditions. Tribology Letters 45(2): 333–339 (2012)

Deleanu L, Georgescu C. Water lubrication of PTFE composites. Industrial Lubrication and Tribology 67(1): 1–8 (2015)

Chen B, Wang J, Liu N, Yan F. Synergetic Effect of Lubricant Additive and Reinforcement Additive on the Tribological Behaviors of PEEK-Based Composites under Seawater Lubrication. Tribology Transactions 56(4): 672–680 (2013)

Zhang Z, Nie S, Liao W, Li L, Yuan S. Tribological behaviors of carbon fiber reinforced polyetheretherketone sliding against silicon carbide ceramic under seawater lubrication. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology 228(12): 1421–1432 (2014)

Mimaroglu A, Unal H, Ozel A. Tribological Performance of Polyetheretherketone and its Composites under Water Environment. Macromolecular Symposia 327(1): 108–113 (2013)

Tomizawa H, Fischer T E. Friction and wear of silicon nitride and silicon carbide in water: hydrodynamic lubrication at low sliding speed obtained by tribochemical wear. ASLE Transactions 30(1): 41–46 (1987)

Li J J, Luo J B. Advancements in superlubricity. Science China Technological Sciences 56(12): 2877–2887 (2013)

Chen Z, Liu Y, Luo J. Superlubricity of nanodiamonds glycerol colloidal solution between steel surfaces. Colloids and Surfaces A: Physicochemical and Engineering Aspects 489: 400–406 (2016)

Lifang C, Chengya H, Xing H. Actuality and Prospect in Research on Friction and Wear Properties of Polymers and Polymer-based Composites. Lubrication Engineering- Huangpu 6(172): 183 (2005)

Zhao J, He Y, Wang Y, Wang W, Yan L, Luo J. An investigation on the tribological properties of multilayer graphene and MoS2, nanosheets as additives used in hydraulic applications. Tribology International 97:14–20 (2016)

Yang Y, Zhang C, Wang Y, Dai Y, Luo J. Friction and wear performance of titanium alloy against tungsten carbide lubricated with phosphate ester. Tribology International 95: 27–34 (2016)

Xie G, Liu S, Guo D, Wang Q, Luo J. Investigation of the running-in process and friction coefficient under the lubrication of ionic liquid/water mixture. Applied Surface Science 255(12): 6408–6414 (2009)

Ma Z Z, Zhang C H, Liu S H, Luo J, Lu X, Wen S. Study of lubrication behavior of pure water for hydrophobic friction pair. Science in China Series E: Technological Sciences 52(11): 3128–3134 (2009)

Heshmat H, Jahanmir S. Tribological behavior of ceramics at high sliding speeds in steam. Tribology Letters 17 (3): 359–366 (2004)

Satapathy B, Bijwe J. Analysis of simultaneous influence of operating variabales on the abrasive wear of phenolic Composite. Wear 253: 787–794 (2002)

Mens J W M, Gee A W J. Friction and wear behaviour of 18 polymers in contact with steel in environments of air and water. Wear 149: 255–268 (1991)

Zhang Z Y, Zhang M Q, Zeng H M, Liu Z R. On the tribological behavior and mechanism of Poly (etherether ketone). Acta Materiae Compositae Sinica 4 (1995)

Unal H, Mimaroglu A, Kadioglu U, Ekiz H. Sliding friction and wear behaviour of polytetrafluoroethylene and its composites under dry conditions. Materials & Design 25(3): 239–245 (2004)

Jia Z N, Hao C Z, Yan Y H. Effects of different operation conditions on the self lubricating properties of PI/PTFE composites. CHINA PLASTICS INDUSTRY 11: 021 (2014)

Jia J, Zhou H, Gao S, et al. The tribological behavior of carbon-fiber-reinforced polyimide composites under water lubrication. (in Chinese). Mocaxue Xuebao 22: 273–276 (2002)

Xiong D, Ge S. Friction and wear properties of UHMWPE/ Al2O3 ceramic under different lubricating conditions. Wear 250(1): 242–245 (2001)

Jia J, Gao S, Chen J, et al. Tribological properties and wear mechanisms of PTFE and carbon fiber reinforced PI composites. (in Chinese). Materials Science and Engineering 21: 183–186 (2003)

Wang X, Adachi K, Otsuka K, Kato K. Optimization of the surface texture for silicon carbide sliding in water. Applied Surface Science 253(3): 1282–1286 (2006)

Wang X, Kato K, Adachi K, Aizawa K. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribology International 36(3): 189–197 (2003)

Gao Y, Ma L, Luo J. Pitted Surfaces Produced by lactic acid lubrication and their effect on ultra-low friction. Tribology Letters 57(2): 1–8 (2015)

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Nos. 51375333, 50975199 and 51205285). Also the author thanks for all the members who have contributed their time and help in this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Anying WANG. She joined the Key Laboratory of Advanced Ceramics and Machining Technology of Ministry of Education at Tianjin University from 2013. Currently, she is a Ph.D. student in mechanical engineering at Tianjin University. Her research interests include ceramics tribology and polymer composite materials tribology.

Bin LIN. He was the lecturer, associate professor, and professor in the School of Mechanical Engineering at Tianjin University in 1994, 1996, and 2007, respectively. His current identity is a Doctoral supervisor and the Vice-director of the the Key Laboratory of Advanced Ceramics and Machining Technology of Ministry of Education. His research areas cover machining theory and machining technology of hard, brittle materials, and structural ceramics application theory and technology.

Rights and permissions

Open Access: The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wang, A., Yan, S., Lin, B. et al. Aqueous lubrication and surface microstructures of engineering polymer materials (PEEK and PI) when sliding against Si3N4. Friction 5, 414–428 (2017). https://doi.org/10.1007/s40544-017-0155-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-017-0155-9