Abstract

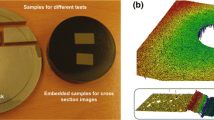

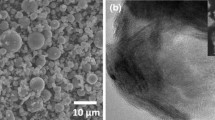

N-doped ZnO thin films were deposited on 304L stainless steel through the pyrolysis of zinc acetate and ammonium acetate in different ratios at a temperature of 420 °C using metal organic chemical vapor deposition. Compositional and structural analyzes of the films were performed by using Rutherford backscattering spectroscopy and X-ray diffraction. The frictional behavior of the thin films and 304L stainless steel substrate was evaluated using a ball-on-flat configuration with reciprocating sliding under marginally lubricated and fully flooded conditions. Al alloy (2017) was used as ball counterface, while basestock synthetic polyalfaolefin oil (PAO10) without additives was used as lubricant. The flat and ball counterface surfaces were examined to assess the wear dimension and failure mechanism. Under marginally lubricated condition, N-doped ZnO thin films provided significant reduction in friction, whereas the films have minimal or no effect in friction under fully flooded condition. N-doped ZnO thin films showed a significant effect in protecting the ball counterface as wear volume was reduced compared with that of the substrate under the marginally lubricated condition. Under the fully flooded condition, with the exception of one of the films, the wear volume of the N-doped ZnO thin films ball reduced compared with that of the substrate. In all the ball counterfaces for N-doped ZnO thin films under both conditions, wear occurred through abrasive mechanism of various degrees or mild polishing. Thus, superfluous lubrication of N-doped ZnO thin films is not necessary to reduce friction and wear.

Article PDF

Similar content being viewed by others

References

Khorramain B A, Iyer G R, Kodali S, Natarajan P, Tupil R. Review of antiwear additives for cranckcase oils. Wear 169: 87–95 (1993)

Zhou X D, Wu D M, Shi H Q, Fu X, Hu Z S, Wang X B, Yan F Y. Study on the tribological properties of surfactantmodified MoS2 micrometer spheres as an additive in liquid paraffin. Tribol Int 40: 863–868 (2007)

Song X, Qiu Z, Yang X, Gong H, Zheng S, Cao B, Wang H, Möhwald H, Schukin D. Submicron-lubricant based on crystalline Fe3O4 spheres for enhanced tribology performance. Chem Mater 26: 5113–5119 (2014)

Harnandez-Battez A, Gonzàlez R, Viesca J L, Fernandez J E, Fernandez J M D, Machado A, Chou R, Riba J. CuO, ZrO2 and ZnO nanoparticles as antiwear additive in oil lubricants. Wear 265: 422–428 (2008)

Radice S, Mischler S. Effect of electrochemical and mechanical parameters on the lubrication behavior of Al2O3 nanoparticles in aqueous suspension. Wear 261: 1032–1041 (2006)

Hu X, Gong H, Wang Y, Chen Q, Zhang J, Zheng S, Yang X, Cao B. Laser induced reshaping of particles aiming at energy saving applications. J Mater Chem 22: 15947–15952 (2012)

Zabinski J S, Corneille J, Prasad S V, Mc Devitt N T, Bultman J B. Lubricious zinc oxide films: Synthesis, characterization and tribological behavior. J Mater Sci 32: 5313–5319 (1997)

Prasad S V, Zabinski J S. Tribological behavior of nanocrystalline zinc oxide films. Wear 203–204: 498–506 (1997)

Prasad S V, Walck S D, Zabinski J S. Microstructural evolution in lubricious ZnO films grown by pulsed laser deposition. Thin Solid Films 360: 107–117 (2000)

Zabinski J S, Sanders J H, Nainaparampil J, Prasad S V. Lubrication using a microstructurally engineered oxide: Performance and mechanism. Tribol Lett 8: 103–116 (2000)

Chai C, Lu X, He D. Atomic layer deposition of zinc oxide films: Effects of nanocrystalline characteristics on tribological performance. Surf Coat Technol 207: 361–366 (2012)

Hu X, Gong H, Wang Y, Chen Q, Zhang J, Zheng S, Yang X, Cao B. Laser induced reshaping of particles aiming at energy saving applications. J Mater Chem 22: 15947–15952 (2012)

Li W, Zheng S, Wang P, Chen Q, Song X, Cao B. Preparation of ZnO nanoparticles with enhanced antifriction properties. Asian J Chem 24: 2753–2756 (2012)

Prasad S V, Nainaparampil J J, Zabinski J S. Tribological behavior of alumina doped zinc oxide films grown by pulsed laser deposition. J Vac Sci Technol A 20: 1738–1743 (2002)

Penkov O V, Lee D H, Kim H, Kim D E. Frictional behavior of atmospheric plasma jet deposited carbon-ZnO composite coatings. Composite Sci Technol 77: 60–66 (2013)

Wang S, Ge S, Zhang D. Comparison of tribological behavior of nylon composite filled with zinc oxide particles and whiskers. Wear 266: 248–254 (2009)

Liu B, Yang Z, Zhou J. Tribological behavior of polyimide zinc oxide hybrid films. Adv Mater Res 106: 438–445 (2010)

Chakraborty H, Sinha A, Mukherjee N, Ray D, Chattopadhyay P P. A study of nanocrystalline and tribological behavior of multifunctional ZnO/PMMA nanocomposite. Mater Lett 93: 137–140 (2013)

Chang B P, Akil H M, Nasir R B M. Composite study of micro- and nano-ZnO reinforced UHMWPE composites under dry sliding. Wear 297: 1120–1127 (2013)

Duan G, Hu X, Song X, Qiu Z, Gong H, Cao B. Morphology evolution of ZnO submicron particles induced by laser irradiation and their enhanced tribology properties by compositing with Al2O3 nanoparticles. Adv Eng Mater 17: 341–348 (2015)

Qin H, Li W, Xia Y, He T. Photocatalytic activity of heterostructures based on ZnO and N-doped ZnO. ACS Appl Mater Interfaces 3: 3152–3156 (2011)

Macias-Sanchez J J, Hinojosa-Reyes L, Caballero-Quintero A, de la Cruz W, Ruiz-Ruiz E, Hernandez-Ramireza A, Guzman-Mar J L. Synthesis of nitrogen-doped ZnO by sol gel method: Characterization and its application on visible photocatalytic degradation of 2, 4-D and picloram herbicides. Photochem Photobiol Sci 14: 536–542 (2015)

Herring N P, Panchakarla L S, El-Shall M S. P-type nitrogen-doped ZnO nanostructures with controlled shape and doping level by facile microwave synthesis. Langmuir 30: 2230–2240 (2014)

Naouar M, Ka I, Gaidi M, Alawadhi H, Bessais B, El Khakani M A. Growth structure and optoelectronic properties tuning of nitrogen-doped ZnO thin films synthesized by means of reactive pulse laser deposition. Mater Res Bull 57: 47–51 (2014)

Allenic A, Guo W, Chen Y B, Zhao G Y, Pan X Q, Che Y, Hu Z D, Liu B. Synthesis and properties of p-type nitrogendoped ZnO thin films by pulsed laser ablation of a Zn-rich Zn3N2 target. J Mater Res 22: 2339–2344 (2007)

Lavand A B, Malghe Y S. Synthesis, characterization and visible light photocatalytic activity of nitrogen-doped zinc oxide nanospheres. J Asian Ceramic Soc 3: 305–310 (2015)

Mbamara U S, Olofinjana B, Ajayi O O, Lorenzo-Martin C, Obiajunwa E I, Ajayi E O B. Friction and wear behavior of nitrogen-doped ZnO thin films deposited via MOCVD under dry contact. Eng Sci Technol 19: 956–963 (2016)

Ajayi O B, Akanni M S, Lambi J N, Jeynes C, Watt J F. Compositional studies of various metal oxide coatings on glass. Thin Solid Films 185: 123–136 (1990)

Ajayi O B, Ojo I A, Jeynes C. Preparation and characterization of MOCVD thin films of cadmium sulphide. Thin Solid Films 248: 57–62 (1994)

Adedeji A V, Eleruja M A, Ojo I A O, Djebah A, Osasona O, Olowolafe J O, Aladekomo J B, Ajayi E O B. Preparation and characterization of MOCVD ZnCdInS thin films. Opt Mater 14: 345–349 (2000)

Adedeji A V, Egharevba G O, Jeynes C, Ajayi E O B. Preparation and characterization of pyrolytically deposited (CO-V-O and Cr-V-O) thin films. Thin Solid Films 402: 49–54 (2002)

Ilori O O, Osasona O, Eleruja M A, Egharevba G O, Adegboyega G A, Chiodeli G, Boudreault G, Jeynes C, Ajayi E O B. Preparation and characterization of metallorganic chemical vapor deposited LixMoyOz using a single source solid precursor. Ionics 11: 387–391 (2005)

Olofinjana B, Egharevba G O, Eleruja M A, Jeynes C, Adedeji A V, Akinwunmi O O, Taleatu B A, Mordi C U, Ajayi E O B. Synthesis and some properties of metal organic chemical vapor deposited molybdenum oxysulphide thin films. J Mater Sci Technol 26: 552–557 (2010)

Olofinjana B, Egharevba G, Teleatu B, Akinwunmi O, Ajayi E O. MOCVD of molybdenum sulphide thin film via single solid source precursor Bis-(Morpholinodithioato-S,S’)- Mo. J Mod Phys 2 341–349 (2011)

Mbamara U S, Olofinjana B, Lorenzo-Martin C, Ajayi O O, Obiajunwa E I, Ajayi E O B. Surface statistical topographical properties of ZnO:N thin films deposited by MOCVD. J NanoSci NanoEng 1: 18–22 (2015)

Mbamara U S, Akinwunmi O O, Obiajunwa E I, Ojo I A O, Ajayi E O B. Deposition and characterization nitrogendoped zinc oxide thin films by MOCVD using zinc acetateammonium acetate precursor. J Mod Phys 3: 652–659 (2012)

Xu W, Ye Z, Zhou T, Zhao B, Zhu L, Huang J. Low pressure MOCVD growth of p-type ZnO thin films by using NO as the dopant source. J Cryst Growth 265: 133–136 (2004)

Tan S T, Chen B J, Sun X W, Yu M B, Zhang X H, Chua S J. Realization of intrinsic p-type ZnO thin films by metal organic vapor deposition. J Electron Mater 34: 1172–1176 (2005)

Qu J, Blau P J, Zhang L, Xu H. Effect of multiple treatment of low-temperature colossal supersaturation on tribological characteristic of austenitic stainless steel. Wear 265: 1909–1913 (2008)

Schön J. Coefficient of friction for aluminum in contact with a carbon fiber epoxy composite. Tribol 137: 395–404 (2004)

Schön J. Coefficient of friction of composite delamination surfaces. Wear 237: 77–89 (2000)

Qu J, Blau P J, Jolly B C. Tribological properties of stainless steel treated by colossal carbon supersaturation. Wear 263: 719–726 (2007)

Lorenzo-Martin C, Ajayi O, Erdemir A, Fenske G R, Wei R. Effect of microstructure and thickness on the friction and wear behavior of CrN coatings. Wear 302: 963–971 (2013)

Budinski K G, Budinski M K. Engineering Materials, Properties and Selection. New Jersey (USA): Prentice Hall, 2002.

Acknowledgements

This work was supported by U.S. Department of Energy, Energy Efficiency and Renewable Energy, Office of Vehicle Technologies, under contract DEAC02- 06CH11357. The authors are also grateful to Center for Research and Development, Obafemi Awolowo University, Ile-Ife, Nigeria, for RBS and XRD analyses.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Bolutife OLOFINJANA. He received his bachelor, M.Sc., and Ph.D. degrees in enigineering physics from Obafemi Awolowo University, Ile-Ife, Nigeria in 1999, 2005, and 2011, respectively. He joined Obafemi Awolowo University as an assistant lecturer in the department of Physics and Engineering Physics. He is currently a senior lecturer in the same department. His research interests include surface modification for active control of friction and wear, and preparation and characterization of nano-structured materials for various applications.

Rights and permissions

Open Access: The articles published in this journal are distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Olofinjana, B., Mbamara, U.S., Ajayi, O. et al. Tribological behavior of N-doped ZnO thin films by metal organic chemical vapor deposition under lubricated contacts. Friction 5, 402–413 (2017). https://doi.org/10.1007/s40544-017-0154-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40544-017-0154-x