Abstract

YBa2Cu3O7-δ (YBCO)-coated conductors have wide-ranging potential in large-scale applications such as superconducting maglev trains and superconducting electric cables, but low current carrying capability restrains the practical application of YBCO-coated conductors at high temperatures and high magnetic fields. It is crucial to develop YBCO-coated conductors with high critical current density. In this paper, epitaxial, dense, smooth, and crack-free Fe-doped YBCO films were prepared on a LaAlO3 single crystal substrate via a fluorine-free polymer-assisted metal organic deposition method. The effects of the dilute Fe doping on microstructure and superconducting character of YBCO films were investigated. The critical temperature for superconducting of the Fe-doped YBCO films decreases slightly. However, the in-field critical current density of YBCO films improves with dilute Fe doping of amounts less than x = 0.005, compared to the pure YBCO film. Therefore, the current carrying capability of YBCO film can improve by doping with appropriate amounts of Fe. This means that dilute Fe doping in YBCO films may be a feasible way to prepare high-performance coated conductors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

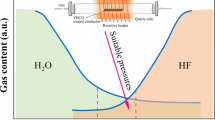

Recently, worldwide attention has been paid to the preparation of YBa2Cu3O7-δ (YBCO)-based coated conductors, i.e., the second generation tapes because of their wide-ranging potential in large-scale application such as superconducting maglev trains and superconducting electric cables [1–7]. The major approaches for fabricating YBCO-coated conductors include in situ processes like pulse laser deposition (PLD), magnetic sputtering, etc., as well as ex situ wet-chemistry approaches. Chemical solution deposition (CSD) and related techniques provide versatile and cost-effective processing routes with controlled stoichiometry and microstructure [8–12]. Therefore, CSD is a preferred fabrication method. In the early work preparing solution-derived REBCO thin films, the critical current densities were quite limited. It was widely believed that organic-based precursors might lead to the formation of stable BaCO3, which accumulates and precipitates at the grain boundaries (GBs) of REBCO and thus significantly reduces the transport critical current density Jc [13]. In an effort to solve this problem, a promising approach using trifluoroacetates metal organic deposition was developed to deposit YBCO films [14, 15]. However, the process leads to the formation of HF which is hazardous, and the microstructure of YBCO films were relatively porous [16], which limits the current transport properties. Alternatively, if the formation of BaCO3 can be well controlled, a kind of novel non-fluorine chemical solution deposition method is a promising and cost-effective approach to the preparation and application of high performance YBCO films. In this paper, YBCO films were prepared using a non-fluorine chemical solution deposition method which was devised in our laboratory [17–19].

The large-scale application of YBCO-coated conductors in superconducting magnets, generators, motors, etc., is prevented because of relatively low current carrying capability with increasing magnetic field and temperature. Therefore, enhancing the Jc is crucial for the practical applications of the YBCO-coated conductors at high temperatures and high magnetic fields. Several methods for increasing the density and effectiveness of vortex pinning sites to enhance Jc were developed by generating artificial defects [20–23]. Studies have confirmed that incorporation of impurities such as Co, Fe, Ga, Zn, Ni, etc., to the Cu sites of YBCO can significantly increase the critical current density versus magnetic field (Jc–H) characteristics of high temperature superconductor bulks [24–26]. Dilute impurity doping to the CuO chain not only enhances flux pinning by lattice deformation but also results in a decrease in critical temperature (Tc) [24]. There are few reports about the doping effects of these dilute impurities in YBCO films [27, 28], especially those prepared with fluorine-free metal organic deposition (MOD).

The authors have previously published results of cobalt and zinc doping to the copper sites of YBCO [17]. It is a perspective way to essentially improve the current carrying capability of YBCO film. There is no work of Fe doping of YBCO in their early work. Fe is cheap and easy to obtain, so it is a perspective material for superconductor production. In this study, different dilute quantities of Fe doping of YBCO were introduced into the MOD YBCO films. Flux pinning properties of dilute Fe-doped YBCO films were investigated. The films were deposited by a fluorine-free polymer-assisted metal organic deposition (PA-MOD) method [17]. Epitaxial, dense, smooth, and crack-free YBCO films were prepared on a LaAlO3 (LAO) single crystal substrate. In-field Jc of YBCO films was improved by this dilute impurity doping method.

2 Experimental

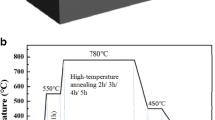

Fe-doped YBa2Cu3-xFe x O7-δ films were deposited on a LaAlO3 (LAO) single crystal substrate using a fluorine-free method [17]. The precursor solutions were synthesized by dissolving acetates of iron, in addition to acetates of yttrium, barium, and copper, in propionic acid with x = 0, 0.0005, 0.001, 0.002, and 0.005. Then polyvinyl butyral was added into the solution, which was subjected to continuous stirring to adjust the viscosity in order to obtain the final coating solution. The final cation concentration of the solution is 0.6 M. Then the solution was coated to LAO using a spin coater with a rotation speed of 6,000 r/min and dried at 150–200 °C for 5–10 min. The coated samples were fabricated in humid Ar/O2 mixture gas at 160–500 °C for 11 h and then fired at 770–800 °C in dry Ar/O2 mixture gas for 1 h. Finally, the samples were annealed in dry O2 gas at 400–450 °C for 1 h. Finally, the obtained YBa2Cu3-xFe x O7-δ-coated films with x of 0–0.005 were about 500 nm in thickness.

A Philips X’Pert MRD diffractometer with Cu-Kα radiation was used to record the θ-2θ X-ray diffraction (XRD) patterns. The microstructure analyses of the YBCO layer were performed using an environmental scanning electron microscope (ESEM). Superconducting transition and magnetic hysteretic loop were measured by Quantum-Design SQUID XL. The Jc value of the YBCO film was determined using Bean critical state model formula.

3 Results and discussion

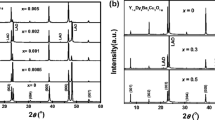

Figure 1 shows the typical θ-2θ X-ray diffraction patterns of YBa2Cu3-xFe x O7-δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films. As can be seen, only (0 0 l) YBCO reflection peaks were detected, excluding the peaks of LAO single crystal substrate. This indicates a strong c-axis orientation for all films.

The microstructure analyses of the YBCO layer were performed, and the results are shown in Fig. 2. Dense, smooth, and crack-free surface morphologies can be observed in all the films. A few particles floating on the film surface may be attributed to texture degradation with the growth of film during the firing procedure. We can see the particles in the Fe-doped YBCO films less than the pure YBCO films. There are some very small pores in the pure YBCO film, but these are not seen in the Fe-doped films. It can be seen that a very small amount of Fe doping improves the surface connectivity of the YBCO films.

Figure 3 shows the superconductivity critical temperature of YBa2Cu3-xFe x O7-δ (x = 0, 0.0005, 0.001, 0.002, and 0.005) films. The inset shows the temperature dependence of magnetic moment for YBa2Cu3-xFe x O7-δ films. The pure YBCO sample exhibits a sharp superconducting transition; while for the doped samples, the superconducting transition width broadens, showing that such Fe doping leads to a decrease of superconductivity. The decrease may be due to the direct iron substitution for copper in the Cu–O chain. The substitution affects the oxygen vacancies which play an important role in determining the transport properties of YBCO. It is found that the superconductivity critical temperature of YBa2Cu3-xFe x O7-δ decreases with Fe doping. When the value of x = 0.005 for YBa2Cu3-xFe x O7-δ, the Tc value is 1.2 K smaller than that of pure YBCO film. It exhibits a very small decrease of Tc because of the small amount of Fe doping.

Figure 4 shows the magnetic field dependence of Jc for YBa2Cu3-xFe x O7-δ (x = 0, 0.0005, 0.001, 0.002, 0.005) films at different temperatures with the magnetic field parallels to the c-axis. The Jc values of Fe-doped YBCO films are not significantly higher than that of pure YBCO films at 30 and 50 K. However, at 77 K, Fe-doped YBCO films possess higher Jc values than those of pure YBCO films, except for the sample with x = 0.005. As 77 K is a feasible temperature for application of YBCO superconductors by using liquid nitrogen, this improved Jc value is significant. It means that the current carrying capability of YBCO film can be improved by doping with appropriate amounts of Fe.

4 Conclusion

In this paper, from the investigation of the Fe doping effects on YBCO films, it can be seen that the critical temperature for superconducting decreases slightly, and Jc improves at 77 K for doping quantities of x less than 0.005.

References

Yao X, Oka A, Izumi T, Shiohara Y (2000) Crystal growth and superconductivity of Fe-doped YBCO single crystals. Physica C 339(2):99–105

Espinosa-Arronte B, Djupmyr M, Andersson M (2005) Scaling of the B-dependent resistivity for different orientations in Fe doped YBa2Cu3O7-δ. Physica C 423(1–2):69–73

Liu LH, Dong C, Zhang JC, Chen H, Chen L (2002) A simple volumetric method for oxygen content determination in high-Tc doped YBCO compositions. Physica C 383(1–2):17–22

Qiao Y, Li Y, Sathiraju S, Reeves J, Lenseth K, Selvamanickam V (2002) An overview of the coated conductor progress at IGC-SuperPower. Physica C 382(1):48–51

Obradors X, Puig T, Pomar A, Sandiumenge F, Mestres N, Coll M, Cavallaro A, Rom N, Gazquez J, Gonzalez JC, Castano O, Gutierrez J, Palau A, Zalamova K, Morlens S, Hassini A, Gibert M, Ricart S, Moreto JM, Pinol S, Isfort D, Bock J (2006) Progress towards all-chemical superconducting YBa2Cu3O7-y coated conductors. Supercond Sci Technol 19(3):s13–s15

Izumi T, Yamada Y, Shiohara Y (2003) Activity of R&D for HTS coated conductors in Japan. Physica C 392–396(1):9–16

Motowidlo LR, Selvamanickam V, Galinski G, Haldar P, Sokolowski RS (2000) Recent progress in high-temperature superconductors at Intermagnetics General Corporation. Physica C 335(1–4):44–50

Parans Paranthaman M, Izumi T (2004) High-performance YBCO-coated superconductor wires. MRS Bull 29(9):533–536

Parans Paranthaman M (2006) Superconductor wires, McGraw-Hill 2006 year book of science and technology. McGraw-Hill, New York, pp 319–322

Goyal A, Norton DP, Budai JD, Paranthaman M, Specht ED, Kroeger DM, Christen DK, He Q, Saffian B, List FA, Lee DF, Martin PM, Klabunde CE, Hatfield E, Sikka VK (1996) Fabrication of long range, biaxially textured, high temperature superconducting tape on rolled Ni substrates. Appl Phys Lett 69(12):1795–1797

Goyal A, Paranthaman M, Schoop U (2004) The RABiTS approach: using rolling-assisted biaxially textured substrates for high-performance YBCO superconductors. MRS Bull 29(9):552–561

Rupich MW, Verebelyi DT, Zhang W, Kodenkandath T, Li X (2004) Metalorganic deposition of YBCO films for second-generation high-temperature superconductor wires. MRS Bull 29(9):572–578

Parmigiani F, Chiarello G, Ripamonti N, Goretzki H, Roll U (1987) Observation of carboxylic groups in the lattice of sintered Ba2YCu3O7-y high-T c superconductors. Phys Rev B 36(13):7148–7150

Honjo T, Nakamura Y, Teranishi R, Fuji H, Shibata J, Izumi T, Shiohara Y (2003) Growth mechanism of YBCO films in metal organic deposition method using trifluoroacetates. IEEE Trans Appl Supercond 13(2):2516–2519

Minei T, Tanaka T, Ogata M, Mori N, Yamada K, Mukaida M (2006) Growth process and microstructure of Y123 film fabricated by advanced TFA-MOD process. Physica C 445–448(1):570–573

Castano O, Cavallaro A, Palau A, Gonzalez JC, Rosell M, Puig T, Pinol S, Mestres N, Sandiumenge F, Pomar A, Obradors X (2003) Influence of porosity on the critical currents of trifluoroacetate-MOD YBa2Cu3O7 films. IEEE Trans Appl Supercond 13(2):2504–2507

Wang WT, Pu MH, Yang Y, Zhang H, Cheng CH, Zhao Y (2010) Enhanced flux-pinning in fluorine-free MOD YBCO films by chemical doping. Physica C 470(20):1261–1265

Wang WT, Li G, Pu MH, Sun RP, Zhou HM, Zhang Y, Zhang H, Yang Y, Cheng CH, Zhao Y (2008) Chemical solution deposition of YBCO thin film by different polymer additives. Physica C 468(15–20):1563–1566

Zhao Y, Pu MH, Li G, Du XH, Zhou HM, Zhang YB, Yang XS, Wang Y, Sun RP, Cheng CH (2007) Development of a new series of buffer layers for REBCO coated conductors. Physica C 463–465(1):574–579

Feng Y, Pradhan AK, Zhao Y, Wu Y, Koshizuka N, Zhou L (2001) Improved flux pinning in Y x Ho1-xBa2Cu3O y fabricated by powder melting process. Supercond Sci Technol 14(4):224–228

Babu NH, Shi YH, Iida K, Cardwell DA (2005) A practical route for the fabrication of large single-crystal (RE)–Ba–Cu–O superconductors. Nat Mater 4(1):476–480

Werner M, Sauerzopf FM, Weber HW, Wisniewski A (2000) Fishtail effect in the magnetization of superconducting RBa2Cu3O7-δ (R = Y, Nd, Yb) and Y2Ba4Cu8O16 single crystals. Phys Rev B 61(21):14795–14803

Sauerzopf FM (1998) Anisotropic flux pinning in YBa2Cu3O7-δ single crystals: the influence of defect size and density as determined from neutron irradiation. Phys Rev B 57(17):10959–10971

Ishii Y, Shimoyama JI, Tazaki Y, Nakashima T, Horii S, Kishio K (2006) Enhanced flux pinning properties of YBa2Cu3O y by dilute impurity doping for CuO chain. Appl Phys Lett 89(11):202514–202517

Zhou YX, Scruggs S, Salama K (2006) Effects of ionic doping superconducting properties of melt textured YBa2(Cu1-xM x )3O7-δ (M = Co, Ni, Zn or Ga) large grains. Supercond Sci Technol 19(7):S556–S558

Pan SH, Hudson EW, Lang KM, Eisaki H, Uchida S, Davis JC (2000) Imaging the effects of individual zinc impurity atoms on superconductivity in Bi2Sr2CaCu2O8+δ. Nature 403(2):746–750

Ohazama T, Mukaida M, Horii S, Saito A, Kita R, Ichinose A, Yoshida Y, Matsumoto K, Ohshima S (2005) Low surface resistance Zn-doped ErBa2Cu3O7-δ thin films. Physica C 426–431(2):1611–1615

Horii S, Ichino Y, Yoshida Y, Matsumoto K, Mukaida M, Ichinose A, Shimoyama J, Kishio K (2006) Dilute Co-doping effects on critical current properties in PLD-ErBa2Cu3O y films. Physica C 445–448(1):837–840

Acknowledgments

This research was supported by the Specialized Research Fund for the Doctoral Program of Higher Education (200806131034, 200806130023), Natural Science Foundation of China under Contract Nos. 50672078 and 50872116, the National Science Fund for Distinguished Young Scholars under Contract No. 50588201, and 51102199, the National High-Tech Program of China (863 Program) under Contract No. 2007AA03Z203, the PCSIRT of the Ministry of Education of China (IRT0751), Research and Development Foundation of Southwest Jiao tong University under Grant Contract No. 2004A02, Fundamental Research Funds for the Central Universities (SWJTU12CX019), the National Natural Science Foundation (51202202), and Fundamental Research Funds for the Central Universities of China (SWJTU2682013CX005).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

This article is published under license to BioMed Central Ltd.Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Zhang, H., Zhao, Y., Wang, W. et al. Fe-doped epitaxial YBCO films prepared by chemical solution deposition. J. Mod. Transport. 22, 45–49 (2014). https://doi.org/10.1007/s40534-014-0034-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40534-014-0034-2