Abstract

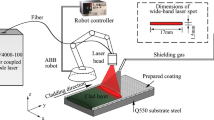

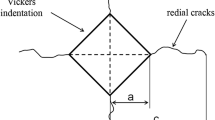

In this work, the process of laser surface cladding was used for deposition of multilayer coatings using repetitively pulsed CO2 laser radiation. As a material for deposition a powder mixture based on a nickel–chromium heat-resistant alloy with an additive reinforcing ceramic WC particles was used. The cladding parameters such as radiation power, scanning speed, laser beam diameter were optimized. The possibility of forming a multilayer ceramic–metal coating without pores and cracks and with ceramic concentration of 40 wt. % was shown. It was also demonstrated that with an increase in the concentration of tungsten carbide, the microhardness increased above 1000 HV0.3 for 40% NiCrBSi—60% WC coating. A study on the wear resistance of the samples showed that the NiCrBSi—WC 6:4 wt. coating is 2.5–2.7 times better compared to the coating without ceramic particles. Using X-ray phase analysis, it was found that during laser exposure, secondary reinforcing phases were formed in the melt bath, such as CrB, Cr23C6, W2C, and W2B.

Similar content being viewed by others

Code Availability

Not applicable.

References

Zhang, Z., Yu, T., Kovacevic, R.: Erosion and corrosion resistance of laser cladded AISI 420 stainless steel reinforced with VC. Appl. Surf. Sci. 410, 225–240 (2017)

M P,: Additive Manufacturing of Tungsten Carbide Hardmetal Parts by Selective Laser Melting (SLM), Selective Laser Sintering (SLS) and Binder Jet 3D Printing (BJ3DP) Techniques. Lasers Manuf. Mater. Process. 7, 338–371 (2020)

Fernández, M.R., García, A., Cuetos, J.M., González, R., Noriega, A., Cadenas, M.: Effect of actual WC content on the reciprocating wear of a laser cladding NiCrBSi alloy reinforced with WC. Wear 324–325, 80–89 (2015)

Fomin, V.M., Golyshev, A.A., Kosarev, V.F., Malikov, A.G., Orishich, A.M., Filippov, A.A.: Deposition of Cermet Coatings on the Basis of Ti, Ni, WC, and B4C by Cold Gas Dynamic Spraying with Subsequent Laser Irradiation. Phys. Mesomech. 23, 291–300 (2020)

Zhang, D., Zhang, X.: Laser cladding of stainless steel with Ni–Cr3C2 and Ni–WC for improving erosive–corrosive wear performance. Surf. Coatings Technol. 190, 212–217 (2005)

Farahmand, P., Liu, S., Zhang, Z., Kovacevic, R.: Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La2O3. Ceram. Int. 40, 15421–15438 (2014)

Fomin, V.M., Golyshev, A.A., Malikov, A.G., Orishich, A.M., Filippov, A.A.: Creation of a Functionally Gradient Material By the Selective Laser Melting Method. J. Appl. Mech. Tech. Phys. 61, 878–887 (2020)

Padmakumar, M., Dinakaran, D.: A review on cryogenic treatment of tungsten carbide (WC-Co) tool material. Mater. Manuf. Process. 36, 637–659 (2021)

Zhou, S., Lei, J., Dai, X., Guo, J., Gu, Z., Pan, H.: A comparative study of the structure and wear resistance of NiCrBSi/50 wt.% WC composite coatings by laser cladding and laser induction hybrid cladding. Int. J. Refract. Met. Hard Mater. 60, 17–27 (2016)

Li, M., Han, B., Wang, Y., Song, L., Guo, L.: Investigation on laser cladding high-hardness nano-ceramic coating assisted by ultrasonic vibration processing. Optik. (Stuttg). 127, 4596–4600 (2016)

Yang, G., Huang, C., Song, W., Li, J., Lu, J., Ma, Y., Hao, Y., Yang, G., Huang, C., Song, W., Li, J., Lu, J., Ma, Y., Hao, Y.: Microstructure characteristics of Ni/WC composite cladding coatings. Int. J. Miner. Metall. Mater. 23, 184–192 (2016)

Raghavendra, C.R., Basavarajappa, S., Sogalad, I., Kumar, S.: A review on Ni based nano composite coatings. Mater. Today Proc. 39, 6–16 (2021)

Eklund, J., Phother, J., Sadeghi, E.: High-Temperature Corrosion of HVAF-Sprayed Ni-Based Coatings for Boiler Applications. Oxid. Met. 915(91), 729–747 (2019)

Abioye, T.E., Farayibi, P.K., McCartney, D.G., Clare, A.T.: Effect of carbide dissolution on the corrosion performance of tungsten carbide reinforced Inconel 625 wire laser coating. J. Mater. Process. Technol. 231, 89–99 (2016)

Weng, Z., Wang, A., Wu, X., Wang, Y., Yang, Z.: Wear resistance of diode laser-clad Ni/WC composite coatings at different temperatures. Surf. Coatings Technol. 304, 283–292 (2016)

Wu, P., Du, H.M., Chen, X.L., Li, Z.Q., Bai, H.L., Jiang, E.Y.: Influence of WC particle behavior on the wear resistance properties of Ni–WC composite coatings. Wear 257, 142–7 (2004)

Liang, G.Y., Wong, T.T.: Investigation of microstructure of laser cladding Ni-WC layer on Al-Si alloy. J. Mater. Eng. Perform. 61(6), 41–45 (1997)

Xu, J.S., Zhang, X.C., Xuan, F.Z.: Microstructure and sliding wear resistance of laser cladded WC/Ni composite coatings with different contents of WC particle. J. Mater. Eng. Perform. 219(21), 1904–1911 (2011)

Duraiselvam, M., Galun, R., Wesling, V., Mordike, B.L.: Laser clad WC reinforced Ni-based intermetallic-matrix composites to improve cavitation erosion resistance. J. Laser Appl. 18, 297 (2006)

Sadhu, A., Choudhary, A., Sarkar, S., Nair, A.M., Nayak, P., Pawar, S.D., Muvvala, G., Pal, S.K., Nath, A.K.: A study on the influence of substrate pre-heating on mitigation of cracks in direct metal laser deposition of NiCrSiBC-60%WC ceramic coating on Inconel 718. Surf. Coatings Technol. 389, 125646 (2020)

Ning, J., Sievers, D.E., Garmestani, H., Liang, S.Y.: Analytical modeling of transient temperature in powder feed metal additive manufacturing during heating and cooling stages. Appl. Phys. A Mater. Sci. Process. 125, 1–11 (2019)

Ning, J., Liang, S.Y.: Predictive modeling of machining temperatures with force–temperature correlation using cutting mechanics and constitutive relation. Mater. 12, 284 (2019)

Ning, J.: Analytical modeling of machining forces of ultra-fine-grained titanium. Int. J. Adv. Manuf. Technol. 1011(101), 627–636 (2018)

Ning, J., Liang, S.Y.: A comparative study of analytical thermal models to predict the orthogonal cutting temperature of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 1029(102), 3109–3119 (2019)

Ning, J., Sievers, D.E., Garmestani, H., Liang, S.Y.: Analytical modeling of in-process temperature in powder bed additive manufacturing considering laser power absorption, latent heat, scanning strategy, and powder packing. Mater. 12, 808 (2019)

Yang, Y., Knol, M.F., van Keulen, F., Ayas, C.: A semi-analytical thermal modelling approach for selective laser melting. Addit. Manuf. 21, 284–297 (2018)

Huang, L., Zhou, J., Xu, J., Huo, K., He, W., Meng, X., Huang, S.: Microstructure and wear resistance of electromagnetic field assisted multi-layer laser clad Fe901 coating. Surf. Coatings Technol. 395, 125876 (2020)

Fu, Y., Qi, T., Zong, L., Zheng, L.: Effects of alternating magnetic field on microstructures and mechanics properties of high hardness cladding layers. Zhongguo Jixie Gongcheng/China Mech. 28, 2378–2382 (2017)

Hidouci, A., Pelletier, J.M., Ducoin, F., Dezert, D., El Guerjouma, R.: Microstructural and mechanical characteristics of laser coatings. Surf. Coatings Technol. 123, 17–23 (2000)

Li, M., Han, B., Wang, Y., Pu, K.: Effects of La2O3 on the microstructure and property of laser cladding Ni-based ceramic coating. Optik (Stuttg). 130, 1032–7 (2017)

Li, M., Zhang, Q., Han, B., Song, L., Cui, G., Yang, J., Li, J.: Microstructure and property of Ni/WC/La2O3 coatings by ultrasonic vibration-assisted laser cladding treatment. Opt. Lasers Eng. 125, 105848 (2020)

Kozhemyakin, G.N.: Letter to the editors influence of ultrasonic vibrations on the growth of InSb crystals. J. Cryst. Growth. 149, 266–268 (1995)

He, L., Wu, M., Li, L., Hao, H.: Ultrasonic generation by exciting electric arc: A tool for grain refinement in welding process. Appl. Phys. Lett. 89, 131504 (2006)

Lei, Y., Wang, Z., Chen, X.: Effect of arc-ultrasound on microstructures and mechanical properties of plasma arc welded joints of SiCp/Al MMCs. Trans. Nonferrous Met. Soc. China 21, 272–277 (2011)

Farrow, M.M.: Laser/ultrasonic welding technique. J. Acoust. Soc. Am. 72, 2049 (1998)

Dai, W.-L.: Effects of high-intensity ultrasonic-wave emission on the weldability of aluminum alloy 7075–T6. Mater. Lett. 57, 2447–2454 (2003)

Xu, Z., Yan, J., Wu, G., Kong, X., Yang, S.: Interface structure of ultrasonic vibration aided interaction between Zn–Al alloy and Al2O3p/6061Al composite. Compos. Sci. Technol. 65, 1959–1963 (2005)

Chmielewski, T., Golański, D.A.: New method of in-situ fabrication of protective coatings based on Fe–Al intermetallic compounds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 225, 611–616 (2011)

Piekoszewski, J., Krajewski, A., Prokert, F., Senkara, J., Stanisławski, J., Waliś, L., Werner, Z., Włosiński, W.: Brazing of alumina ceramics modified by pulsed plasma beams combined with arc PVD treatment. Vacuum 70, 307–312 (2003)

Kumar, S., Wu, C.S., Padhy, G.K., Ding, W.: Application of ultrasonic vibrations in welding and metal processing: A status review. J. Manuf. Process. 26, 295–322 (2017)

Kiseleva, T.A., Golyshev, A.A.: The influence of the thermal wake due to pulsating optical discharge on the aerodynamic-drag force. Thermophys. Aeromechanics 252(25), 257–264 (2018)

Golyshev, A., Malikov, A., Orishich, A., Gulov, M., Ancharov, A.: The effect of using repetitively pulsed laser radiation in selective laser melting when creating a metal-matrix composite Ti-6Al-4V–B4C. Int. J. Adv. Manuf. Technol. 2021, 1–14 (2021)

Golyshev, A.A., Malikov, A.G., Orishich, A.M., Shulyatyev, V.B.: Experimental study of laser-oxygen cutting of low-carbon steel using fibre and CO 2 lasers under conditions of minimal roughness. Quantum Electron. 44, 970–4 (2014)

Yan, H., Liu, K., Zhang, P., Zhao, J., Qin, Y., Lu, Q., Yu, Z.: Fabrication and tribological behaviors of Ti3SiC2/Ti5Si3/TiC/Ni-based composite coatings by laser cladding for self-lubricating applications. Opt. Laser Technol. 126, 106077 (2020)

Ancharov, A.I., Manakov, A.Y., Mezentsev, N.A., Tolochko, B.P., Sheromov, M.A., Tsukanov, V.M.: New station at the 4th beamline of the VEPP-3 storage ring. Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip.470, 80–83 (2001)

Golyshev, A.A., Orishich, A.M., Filippov, A.A.: Similarity laws in laser cladding of cermet coatings. J. Appl. Mech. Tech. Phys. 60, 758–767 (2019)

Golyshev, A., Orishich, A.: Microstructure and mechanical characterization of TI6AL4V-B4C metal ceramic alloy, produced by laser powder-bed fusion additive manufacturing. Int. J. Adv. Manuf. Technol. 109, 579–588 (2020)

Deen, K.M., Afzal, M., Liu, Y., Farooq, A., Ahmad, A., Asselin, E.: Improved corrosion resistance of air plasma sprayed WC-12%Co cermet coating by laser re-melting process. Mater. Lett. 191, 34–37 (2017)

Xia, M., Gu, D., Ma, C., Zhang, H., Dai, D., Chen, H., Li, C., Zhou, Z., Chen, G., Kelbassa, I.: Fragmentation and refinement behavior and underlying thermodynamic mechanism of WC reinforcement during selective laser melting of Ni-based composites. J. Alloys Compd. 777, 693–702 (2019)

Huo, K., Zhou, J., Dai, F., Xu, J.: Particle distribution and microstructure of IN718/WC composite coating fabricated by electromagnetic compound field-assisted laser cladding. Appl. Surf. Sci. 545, 149078 (2021)

Ho, I.T., Chen, Y.T., Yeh, A.C., Chen, C.P., Jen, K.K.: Microstructure evolution induced by inoculants during the selective laser melting of IN718. Addit. Manuf. 21, 465–471 (2018)

Funding

This study was funded by state assignment of Ministry of Science and Higher Education of the Russian Federation (project No. 121030900259–0). The work on obtaining images of a scanning electron microscope, determining the energy-dispersed chemical composition was performed using the equipment of the Central Collective Use Center "Mechanics" (ITAM SB RAS).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics Approval

The submitted work is original and dont published elsewhere in any form or language.

Consent to Participate

All authors give their consent.

Consent for Publication

All authors give their consent.

Conflicts of Interest/Competing Interests

The authors declare they have no financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Golyshev, A., Bulina, N. & Gulov, M. Effect of Repetitively Pulsed Laser Radiation on the Morphology, Microstructure and Mechanical Properties of WC – NiCrBSi Coatings Obtained by Laser Surface Cladding. Lasers Manuf. Mater. Process. 9, 590–609 (2022). https://doi.org/10.1007/s40516-022-00193-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-022-00193-3