Abstract

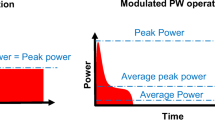

A short-pulsed laser with an ultraviolet wavelength is used for laser micro incisions of wood. In order to solve the technical issue of processing efficiency, the laser oscillation conditions were investigated. The output of this pulsed laser is the product of the pulse energy and the pulse repetition rate, and the output is represented by their two-dimensional planes. For the purpose of understanding the characteristics of processing on wood by this laser, drilling was performed on wood under each condition of this two-dimensional plane. As a result, the hole depth showed an asymptotic tendency with respect to the output increase, and the heat effect and the hole diameter tended to increase. Therefore, it was presumed that both machining quality and its efficiency could be achieved by beam splitting that disperses the output of the beam. In an application example of drilling hundreds of holes per square centimeter at a depth of a few millimeters, it was predicted that the machining time would be halved by applying such a beam splitting device. Moreover, it was considered that the shortening rate could be increased as improving the output of the oscillator. On the other hand, further shortening of pulse width by using the pico-second laser was not considered to be beneficial in the processing of wood. In-process monitoring of the processing phenomenon was examined and the progress of laser drilling was observed.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Ruddick, J.N.R.: Laser incising of Canadian softwood to improve treatability. Forest Prod. J. 41(4), 53–57 (1991)

Goodell, B., Kamke, F.A., Liu, J.: Laser incising of spruce lumber for improved preservative penetration. Forest Prod. J. 41(9), 48–52 (1991)

Hattori, N., Ida, A., Kitayama, S., Noguchi, M.: Incising wood with a 500 watt Carbon-Dioxide laser. Mokuzai Gakkaishi 37, 766–768 (in Japanese) (1991).

Hattori, N., Ando, K., Kitayama, S., Nakamura, Y.: Laser incising of wood - Impregnation of columns with water-soluble dye. Mokuzai Gakkaishi 40, 1381–1388 (in Japanese) (1994)

Wang, Y., Ando, K., Hattori, N.: Changes in the anatomy of surface and liquid uptake of wood after laser incising. Wood Sci. Technol. 47, 447–455 (2013)

Islam, M.N., Ando, K., Yamauchi, H., Kobayashi, Y., Hattori, N.: Comparative study between full cell and passive impregnation method of wood preservation for laser incised Douglas fir lumber. Wood Sci. Technol. 42, 343–350 (2008)

Fukuta, S., Nomura, M., Ikeda, T., Yoshizawa, M., Yamasaki, M., Sasaki, Y.: UV laser machining of wood. Euro. J. Wood Prod. 74(2), 261–267 (2016)

Ikeno, J.: The influence of characteristics of laser light on processing. J. Jpn. Soc. Precis. Eng. 83(6), 514–518 (in Japanese) (2017)

Fukuta, S., Nomura, M., Ikeda, T., Yoshizawa, M., Yamasaki, M., Sasaki, Y.: Wavelength dependence of machining performance in UV-, VIS- and NIR-laser cutting of wood. J. Wood Sci. 62(4), 316–323 (2016)

Wu, R., Seltman, J.: Microstructural investigation of UV-laser irradiated pine (Pinus silvestris L.). Wood Sci. Technol. 32, 183–195 (1998)

Mertens, N., Wolkenhauer, A., Leck, M., Viöl, W.: UV laser ablation and plasma treatment of wooden surfaces - a comparing investigation. Laser Phys. Lett. 3(8), 380–384 (2006)

Fukuta, S., Nomura, M., Ikeda, T., Yoshizawa, M., Yamasaki, M., Sasaki, Y.: UV-laser incisions to apply wood-plastic compositions to wood surfaces. Mokuzai Gakkaishi. 64(1), 28–35 (in Japanese) (2018)

Fukuta, S., Nomura, M., Wakabayashi, K.: Flameproof treatment of wood using laser micro incisions. Wood Industry. 74(2), 52–56 (in Japanese) (2019)

Fukuta, S., Nomura, M., Kurisaki, H., Okamura, H.: Application of laser micro incisions in the fire-retardant treatment. Eur. J. Wood Prod. 80(1), 255–258 (2022)

Nomura, M., Fukuta, S.: Effects of laser micro incisions on weatherability of penetrating-type wood preservative semi-transparent coatings. Wood Ind. 75(2), 62–66 (in Japanese) (2020)

Fukuta, S., Nomura, M., Ikeda, T., Wakabayashi, K.: Processing characteristics of laser micro incising and possibility of its high speed processing. Eur. J. Wood Prod. 77(2), 249–255 (2019)

Ooie, T., Miyamoto, I.: Characteristics of excimer laser-induced iron plasma. Fundamental research of materials processing by excimer laser, report 1. J. Jpn. Weld. Soc. 14(3), 489–494 (1996)

Katz, S., Kaplan, N., Grossinger, I.: Using diffractive optical elements: DOEs for beam shaping - fundamentals and applications. Optik & Photonik 13(4), 83–86 (2018)

Matsumoto, N., Inoue, T., Ando, T., Takiguchi, Y., Ohtake, Y., Toyoda, H.: High-quality generation of a multisport pattern using a spatial light modulator with adaptive feedback. Opt. Lett. 37(15), 3135–3137 (2012)

AdlOptica Optical Systems GmbH: Lossless beam splitting for multi kW lasers. http://adloptica.com/multispot.html (2021) Accessed 30 September 2021

Katanahara, H., Kusumoto, T., Takiguchi, Y.: Effect of ablation properties of various materials with a sub-μs Yb: YAG disk laser. In: Proc. The 91th laser materials processing conference, Osaka, Japan, 20 Jun 2019, pp 155. Japan laser processing society (2019)

Lind, J., Weckenmann, N., Hagenlocher, C., Weber, R., Garf, T.: Analysis and optimization of the piercing process in laser beam cutting by means of high-speed X-ray imaging. J. Manuf. Process. 69, 303–310 (2021)

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Satoshi FUKUTA. The first draft of the manuscript was written by Satoshi FUKUTA and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Process map specifies the most efficient operating region for the LMI of wood, it seems appropriate to use a beam splitting optical system in response to the increased laser output.

• Processing phenomenon can observe in-process easily by transmitted light.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fukuta, S., Nomura, M. A Consideration for Improving the Processing Efficiency of UV-Laser Incisions of Wood. Lasers Manuf. Mater. Process. 9, 503–514 (2022). https://doi.org/10.1007/s40516-022-00186-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-022-00186-2