Abstract

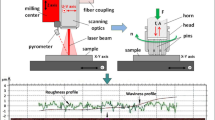

The study and prediction of the structure and hardness in the overlapping area during multi-pass laser heat treatment (LHT) is an important issue for the preparation of the technological process and directly affects the choice of the LHT parameters. The scanner-based laser transformation hardening of the AISI 1045 medium carbon steel and AISI D2 high-chromium tool steel was carried out in a continuous mode using a Rofin Sinar FL010 fiber laser and two-dimensional (2D) optical system. The laser multi-tracks with an overlapping scanning beam of 10%, 25%, and 40% were produced. The computer numerical control programs for the scanner-based laser surface hardening of the large-scale metal parts with various overlapping ratios were developed. The experimental results of the overlapping depth and hardness were compared with the heat-affected zone geometry and Vickers hardness measurements. The microstructure in the laser-hardened and laser-tempered areas is studied by optical microscopy. It was revealed that the overlapping ratio should be selected at 20–25% to obtain the overlapping depth of ~ 400 µm for the studied steels. Unlike carbon steel, the required surface hardness is provided in the laser-tempered zone of the tool steel. To increase the surface hardness in the laser-overlapped area, a multi-pin ultrasonic impact treatment was additionally applied. The results indicated that the severe surface plastic deformation provides the required microhardness in the overlapping area for the AISI 1045 carbon steel.

Similar content being viewed by others

Data Availability

The authors declare that all data generated and/or analyzed during this study are included in this article.

References

Hagino, H., Shimizu, S., Ando, H., Kikuta, H.: Design of a computer-generated hologram for obtaining a uniform hardened profile by laser transformation hardening with a high-power diode laser. Precis. Eng. 34, 446–452 (2010). https://doi.org/10.1016/j.precisioneng.2009.11.001

Santhanakrishnan, S., Kovacevic, R.: Hardness prediction in multi-pass direct diode laser heat treatment by on-line surface temperature monitoring. J. Mater. Process. Technol. 212, 2261–2271 (2012). https://doi.org/10.1016/j.jmatprotec.2012.06.002

Martinez, S., Lamikiz, A., Ukar, E., Tabernero, I., Arrizubieta, I.: Control loop tuning by thermal simulation applied to the laser transformation hardening with scanning optics process. Appl. Therm. Eng. 98, 49–60 (2016). https://doi.org/10.1016/j.applthermaleng.2015.12.037

Trdan, U., Porro, J.A., Ocana, J.L., Grum, J.: Laser shock peening without absorbent coating (LSPwC) effect on 3D surface topography and mechanical properties of 6082–T651 Al alloy. Surf. Coat. Technol. 208, 109–116 (2012). https://doi.org/10.1016/j.surfcoat.2012.08.048

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Lamikiz, A., Prokopenko, G.I., Iefimov, M.O., Grinkevych, K.E.: Combining laser transformation hardening and ultrasonic impact strain hardening for enhanced wear resistance of AISI 1045 steel. Wear 462–463, 203494 (2020). https://doi.org/10.1016/j.wear.2020.203494

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Lamikiz, A.: Wear characteristics of carbon and tool steels hardened by combined laser-ultrasonic surface treatment, In: Ivanov V. et al. (eds) Advances in Design, Simulation and Manufacturing IV. DSMIE 2021. Lect. Notes Mech. Eng. 62–72 (2021). https://doi.org/10.1007/978-3-030-77719-7_7

Lesyk, D.A., Mordyuk, B.N., Martinez, S., Iefimov, M.O., Dzhemelinskyi, V.V., Lamikiz, A.: Influence of combined laser heat treatment and ultrasonic impact treatment on microstructure and corrosion behavior of AISI 1045 steel. Surf. Coat. Technol. 401, 126275 (2020). https://doi.org/10.1016/j.surfcoat.2020.126275

Guarino, S., Barletta, M., Afilal, A.: High Power Diode Laser (HPDL) surface hardening of low carbon steel: Fatigue life improvement analysis. J. Manuf. Process. 28, 266–271 (2017). https://doi.org/10.1016/j.jmapro.2017.06.015

Rodzinak, D., Cernan, J., Zahradnicek, R.: Effect of laser hardening on the properties of PM steels. Acta Metall. Slovaca 19, 282–291 (2013). https://doi.org/10.12776/ams.v19i4.142

Yao, C., Xu, B., Huang, J., Zhang, P., Wu, Y.: Study on the softening in overlapping zone by laser-overlapping scanning surface hardening for carbon and alloyed steel. Opt. Lasers Eng. 48, 20–26 (2010). https://doi.org/10.1016/j.optlaseng.2009.05.001

Kovalenko, V., Zhuk, R.: Systemized approach in laser industrial systems design. J. Mater. Proc. Technol. 149, 553–556 (2004). https://doi.org/10.1016/j.jmatprotec.2004.02.020

Idan, A.F.I., Akimov, O., Golovko, L., Goncharuk, O., Kostyk, K.: The study of the influence of laser hardening conditions on the change in properties of steels. Eastern-European J. Eenter. Technol. 80, 69–73 (2016). https://doi.org/10.15587/1729-4061.2016.65455

Shen, Z., Gu, C., Liu, H., Wang, X.: An experimental study of overlapping laser shock micro-adjustment using a pulsed Nd:YAG laser. Opt. Laser Technol. 54, 110–119 (2013). https://doi.org/10.1016/j.optlastec.2013.05.017

Adebiyi, D.I., Popoola, A.P.I., Pityana, S.L.: Microstructural evolution at the overlap zones of 12Cr martensitic stainless steel laser alloyed with TiC. Opt. Laser Technol. 61, 15–23 (2014). https://doi.org/10.1016/j.optlastec.2014.01.014

Lakhkar, R.S., Shin, Y.C., Krane, M.J.M.: Predictive modeling of multi-track laser hardening of AISI4140 steel. Mater. Sci. Eng. A 480, 209–217 (2008). https://doi.org/10.1016/j.msea.2007.07.054

Tani, G., Orazi, L., Fortunato, A.: Prediction of hypo eutectoid steel softening due to tempering phenomena in laser surface hardening. CIRP Ann. Manuf Technol. 57, 209–212 (2008). https://doi.org/10.1016/j.cirp.2008.03.057

Giorleo, L., Previtali, B., Semeraro, Q.: Modelling of back tempering in laser hardening. Int. J. Adv. Manuf. Technol. 54, 969–977 (2011). https://doi.org/10.1016/j.cirp.2008.03.057

Kibria, G., Doloi, B., Bhattacharyya, B.: Investigation into the effect of overlap factors and process parameters on surface roughness and machined depth during micro-turning process with Nd:YAG laser. Opt. Laser Technol. 60, 90–98 (2014). https://doi.org/10.1016/j.optlastec.2014.01.009

Hu, Y., Yao, Z.: Overlapping rate effect on laser shock processing of 1045 steel by small spots with Nd:YAG pulsed laser. Surf. Coat. Technol. 202, 1517–1525 (2008). https://doi.org/10.1016/j.surfcoat.2007.07.008

Kim, J.D., Lee, M.H., Lee, S.J., Kang, W.J.: Laser transformation hardening on rod-shaped carbon steel by Gaussian beam. Trans. Nonferrous Met. Soc. China 19, 941–945 (2009). https://doi.org/10.1016/S1003-6326(08)60382-9

Li, C., Wang, Y., Zhang, Z., Han, B., Han, T.: Influence of overlapping ratio on hardness and residual stress distributions in multi-track laser surface melting roller steel. Opt. Lasers Eng. 48, 1224–1230 (2010). https://doi.org/10.1016/j.optlaseng.2010.06.010

Liua, A., Previtali, B.: Laser surface treatment of grey cast iron by high power diode laser. Phys. Procedia 5, 439–448 (2010). https://doi.org/10.1016/j.phpro.2010.08.166

Li, C., Wang, Y., Zhan, H., Han, T., Han, B., Zhao, W.: Three-dimensional finite element analysis of temperatures and stresses in wide-band laser surface melting processing. Mater. Des. 31, 3336–3373 (2010). https://doi.org/10.1016/j.matdes.2010.01.054

Lesyk, D.A., Martinez, S., Dzhemelinskyi, V.V., Lamikiz, A., Mordyuk, B.N., Prokopenko, G.I.: Surface microrelief and hardness of laser hardened and ultrasonically peened AISI D2 tool steel. Surf. Coat. Technol. 278, 108–120 (2015). https://doi.org/10.1016/j.surfcoat.2015.07.049

Dzhemelinskyi, V.V., Lesyk, D.A., Goncharuk, O.O., Danyleiko, O.O.: Surface hardening and finishing of metallic products by hybrid laser-ultrasonic treatment. East.-Eur. J. Enterp. Technol. 1, 35–42 (2018). https://doi.org/10.15587/1729-4061.2018.124031

Martinez, S., Lamikiz, A., Tabernero, I., Ukar, E.: Laser hardening process with 2D scanning optics. Phys. Procedia 39, 309–317 (2012). https://doi.org/10.1016/j.phpro.2012.10.043

Qiu, F., Kujanpaa, V.: Surface hardening of AISI 4340 steel by laser linear oscillation scanning. Surf. Eng. 28, 569–575 (2012). https://doi.org/10.1179/1743294412Y.0000000034

Deore, H., Rathod, M.J., Hiwarkar, V.D.: Influence of laser surface hardening on microstructure and mechanical properties of austemperd ductile iron, Int. Conf. Ideas, Impact Innov. Mech. Eng. ICIIIME 2017 1126–1332 (2017).

Schuocker, D., Aichinger, J., Majer, R., Spitzer, O., Rau, A., Harrer, Th.: Improved laser hardening process with temperature control avoiding surface degradation, 8th Int. Conf. Photon. Technol. LANE 2014, 1–5 (2014).

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Danyleiko, O.O.: Combined laser-ultrasonic surface hardening process for improving the properties of metallic products, Ivanov V. et al. (eds) Advances in Design, Simulation and Manufacturing. DSMIE 2018. Lect. Notes Mech. Eng. (2019) 97–107. https://doi.org/10.1007/978-3-319-93587-4_11

Klocke, F., Schulz, M., Grafe, S.: Optimization of the laser hardening process by adapting the intensity distribution to generate a top-hat temperature distribution using freeform optics. Coatings 7, 1357–1366 (2017). https://doi.org/10.3390/coatings7060077

Martinez, S., Lesyk, D.A., Lamikiz, A., Ukar, E., Dzhemelinsky, V.V.: Hardness simulation of over-tempered area during laser hardening treatment. Phys. Procedia 83, 1357–1366 (2016). https://doi.org/10.1016/j.phpro.2016.08.143

Babic, M., Balic, J., Milfelner, M., Belic, I., Kokol, P., Zorman, M., Panjan, P.: Robot laser hardening and the problem of overlapping laser beam. Adv. Prod. Eng. Manag. 8, 25–32 (2013). https://doi.org/10.14743/apem2013.1.150

Cordovilla, F., García-Beltran, A., Sancho, P., Dominguez, J., Ruiz-de-Lara, L., Ocana, J.L.: Numerical/experimental analysis of the laser surface hardening with overlapped tracks to design the configuration of the process for Cr-Mo steels. Mater. Des. 102, 225–237 (2016). https://doi.org/10.1016/j.matdes.2016.04.038

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Lamikiz, A., Prokopenko, G.I., Milman, Yu.V., Grinkevych, K.E.: Microstructure related enhancement in wear resistance of tool steel AISI D2 by applying laser heat treatment followed by ultrasonic impact treatment. Surf. Coat. Technol. 328C, 344–354 (2017). https://doi.org/10.1016/j.surfcoat.2017.08.045

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Lamikiz, A., Prokopenko, G.I., Grinkevych, K.E., Tkachenko, I.V.: Laser-hardened and ultrasonically peened surface layers on tool steel AISI D2: Correlation of the bearing curves’ parameters, hardness and wear. J. Mater. Eng. Perform. 27, 764–776 (2017). https://doi.org/10.1007/s11665-017-3107-7

Martinez, S., Lamikiz, A., Ukar, E., Calleja, A., Arrizubieta, J.A., Lopez de Lacalle, L.N.: Analysis of the regimes in the scanner-based laser hardening process. Opt. Lasers Eng. 200, 72–80 (2016). https://doi.org/10.1016/j.optlaseng.2016.10.005

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Lamikiz, A., Prokopenko, G.I.: Effects of laser heat treatment combined with ultrasonic impact treatment on the surface topography and hardness of carbon steel AISI 1045. Opt. Laser Technol. 111, 424–438 (2019). https://doi.org/10.1016/j.optlastec.2018.09.030

Lesyk, D.A., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V., Danyleiko, O.O.: Effects of the combined laser-ultrasonic surface hardening induced microstructure and phase state on mechanical properties of AISI D2 tool steel, In: Ivanov V. et al. (eds) Advances in Design, Simulation and Manufacturing II. DSMIE 2019. Lect. Notes Mech. Eng. 188–198 (2020). https://doi.org/10.1007/978-3-030-22365-6_19

Milman, Yu.V., Mordyuk, B.N., Grinkevych, K.E., Chugunova, S.I., Goncharova, I.V., Lukyanov, A.I., Lesyk, D.A.: New opportunities to determine the rate of wear of materials at friction by the indentation data. Prog. Phys. Met. 21, 544–579 (2020). https://doi.org/10.15407/ufm.21.04.554

Chen, C., Zeng, X., Wang, Q., Lian, G., Huang, X., Wang, Y.: Statistical modelling and optimization of microhardness transition through depth of laser surface hardened AISI 1045 carbon steel. Opt. Laser. Technol. 124, 105976 (2020). https://doi.org/10.1016/j.optlastec.2019.105976

Ponticelli, G.S., Guarino, S., Giannini, O.: An optimal genetic algorithm for fatigue life control of medium carbon steel in laser hardening process. Appl. Sci. 10, 1401 (2020). https://doi.org/10.3390/app10041401

Hindus, S.J., Kumar, S.H., Arockiyaraj, S.X., Kannan, M.V., Kuppan, P.: Experimental investigation on laser assisted surface tempering of AISI D2 tool steel. Proc. Eng. 97(1489–1495), 1495 (2014). https://doi.org/10.1016/j.proeng.2014.12.432

Goia, F.A., de Lima, M.S.F.: Surface hardening of an AISI D6 cold work steel using a fiber laser. J. ASTM Int. 8, 1–9 (2011). https://doi.org/10.1520/STP153220120035

Ismail, M.I.S., Taha, Z.: Surface hardening of tool steel by plasma arc with multiple passes. Mech. Eng. 5, 53332250 (2014). https://doi.org/10.14716/ijtech.v5i1.156

Chiang, K.-A., Chen, Y.-C.: Laser surface hardening of H13 steel in the melt case. Mater. Lett. 59, 1919–1923 (2005). https://doi.org/10.1016/j.matlet.2005.02.026

Mojtaba, M.M., Moghadam, K.: High power diode laser surface hardening of AISI 4130; statistical modelling and optimization. Opt. Laser Technol. 111, 554–570 (2019). https://doi.org/10.1016/j.optlastec.2018.10.043

Lu, Y., Ehle, L.C., Richter, S., Radel, T.: Influence of multi-pass laser hardening of normalized AISI 4140 on the grain size. Surf. Coat. Technol. 421, 127434 (2021). https://doi.org/10.1016/j.surfcoat.2021.127434

Kirschner, V., Svec, M., Bruthansova, R., Dvorak, L.: The effect of the laser spots overlap on the structure during square parts quenching, J. Achiev. Mater. Manuf. Eng. 64, 34–38 (2014). bwmeta1.element.baztech-4020cb66–0d50–4313–9b86–35db96110916

Lesyk, D.A., Alnusirat, W., Martinez, S., Mordyuk, B.N., Dzhemelinskyi, V.V.: Comparison of the effects of laser, ultrasonic, and combined laser-ultrasonic hardening treatments on surface properties of AISI 1045 steel parts, In: Ivanov V. et al. (eds) Advances in Design, Simulation and Manufacturing IV. DSMIE 2021. Lect. Notes Mech. Eng. 313–322 (2022). https://doi.org/10.1007/978-3-030-91327-4_31

Acknowledgements

This work was financially supported by the EWENT Erasmus Mundus program (Grant No. EW/TG2/UPV/EHU/PhD/29/2013) and the National Academy of Sciences of Ukraine (Project No. 0119U001167), as well as partially supported by the Ministry of Education and Science of Ukraine (Project No. 0122U002389, Project No. 0121U109752) and the Ulam NAWA program (Grant Number BPN/ULM/2021/1/00153).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

The authors declare that there is no conflict of ethical responsibilities.

Consent to Participate and Publish

The authors confirm it.

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lesyk, D.A., Alnusirat, W., Martinez, S. et al. Enhancing hardness in overlapping scanner-based laser area of carbon and tool steel by multi-pin ultrasonic impact peening. Lasers Manuf. Mater. Process. 9, 292–311 (2022). https://doi.org/10.1007/s40516-022-00178-2

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-022-00178-2