Abstract

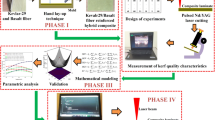

In the present work, basalt and glass layered hybrid composite has been fabricated and thereafter its various mechanical properties have been tested. It has been observed that this hybrid fiber composite has better mechanical properties as compared to basalt fiber reinforced plastic (BFRP) and glass fiber reinforced plastic (GFRP). Conventional machining methods have various limitations viz. fiber pullout, burr formation, etc., which results in poor cut surface quality and degraded mechanical performance. Laser beam machining can be one of the alternatives because it requires low specific energy and supports non-contact machining. However, in order to achieve better cut quality with high precision and accuracy during laser beam machining, selection of favourable range and levels of cutting parameters is quite pertinent. In the present study, Response surface methodology has been used to develop the mathematical models of kerf deviations in terms of input cutting viz. lamp current, pulse frequency, cutting speed, pulse width and compressed air pressure. Well correlation between the predicted and experimental values validates the proposed methodology of ascertaining favourable process parameters during laser machining of basalt – glass hybrid composite. Validation experimental results shows the lowest Top Kerf Deviation (TKD) and Bottom Kerf Deviation (BKD) have been achieved.

Similar content being viewed by others

References

Petrucci R et al. Mechanical and impact characterisation of hybrid composite laminates based on flax, hemp, basalt and glass fibers produced by vacuum infusion. In: ECCM15, 15th European Conference on Composite Materials, 2012

Černý, M., Glogar, P., Sucharda, Z., Chlup, Z., Kotek, J.: Partially pyrolyzed composites with basalt fibres–Mechanical properties at laboratory and elevated temperatures Composites Part A: Applied Science and Manufacturing. 40, 1650–1659 (2009)

Fiore, V., Scalici, T., Di Bella, G., Valenza, A.: A review on basalt fibre and its composites Composites Part B: Engineering. 74, 74–94 (2015)

Nassar, M.M.A., Arunachalam, R., Alzebdeh, K.I.: Machinability of natural fiber reinforced composites: a review The International Journal of Advanced Manufacturing Technology. 88(9-12), 2985–3004 (2017). https://doi.org/10.1007/s00170-016-9010-9

Sim, J., Park, C.: Characteristics of basalt fiber as a strengthening material for concrete structures Composites Part B: Engineering. 36, 504–512 (2005)

Wei, B., Cao, H., Song, S.: RETRACTED: Environmental Resistance and Mechanical Performance of Basalt and Glass Fibers. Elsevier (2010a)

Wei, B., Cao, H., Song, S.: Tensile behavior contrast of basalt and glass fibers after chemical treatment Materials & Design. 31, 4244–4250 (2010b)

High, C., Seliem, H.M., El-Safty, A., Rizkalla, S.H.: Use of basalt fibers for concrete structures Construction and Building Materials. 96, 37–46 (2015)

Pavlovski, D., Mislavsky, B., Antonov, A.: CNG cylinder manufacturers test basalt fibre Reinforced plastics. 51, 36–39 (2007)

Quagliarini, E., Monni, F., Bondioli, F.: Lenci S. Basalt fiber ropes and rods: Durability tests for their use in building engineering Journal of Building Engineering. 5, 142–150 (2016)

Quagliarini, E., Monni, F., Lenci, S.: Bondioli F. Tensile characterization of basalt fiber rods and ropes: A first contribution Construction and Building Materials. 34, 372–380 (2012)

Hao, L., Yu, W.: Evaluation of thermal protective performance of basalt fiber nonwoven fabrics. J Therm Anal Calorim. 100, 551–555 (2009)

Fiore, V., Di Bella, G., Valenza, A.: Glass–basalt/epoxy hybrid composites for marine applications Materials & Design. 32, 2091–2099 (2011)

Abrate S (1997) Machining of composite materials composites engineering handbook(a 98-11526 01-24), New York, Marcel Dekker, Inc(materials Engineering 11:777–810

Davim JP, Oliveira C, Barricas N, Conceição M (2008b) Evaluation of cutting quality of PMMA using CO 2 lasers the international journal of advanced manufacturing technology 35:875-879

Hejjaji, A., Singh, D., Kubher, S., Kalyanasundaram, D.: Gururaja S. Machining damage in FRPs: Laser versus conventional drilling Composites Part A: Applied Science and Manufacturing. 82, 42–52 (2016). https://doi.org/10.1016/j.compositesa.2015.11.036

Leone, C., Genna, S., Tagliaferri, V.: Fibre laser cutting of CFRP thin sheets by multi-passes scan technique Optics and Lasers in Engineering. 53, 43–50 (2014)

Nikumb, S., Chen, Q., Li, C., Reshef, H., Zheng, H., Qiu, H., Low, D.: Precision glass machining, drilling and profile cutting by short pulse lasers. Thin Solid Films. 477, 216–221 (2005)

Solati, A., Hamedi, M., Safarabadi, M.: Combined GA-ANN approach for prediction of HAZ and bearing strength in laser drilling of GFRP composite Optics & Laser Technology. 113, 104–115 (2019)

Mathew, J., Goswami, G.L., Ramakrishnan, N., Naik, N.K.: Parametric studies on pulsed Nd:YAG laser cutting of carbon fibre reinforced plastic composites Journal of Materials Processing Technology. 89-90, 198–203 (1999b). https://doi.org/10.1016/S0924-0136(99)00011-4

Lau, W.S., Lee, W.B., Pang, S.Q.: Pulsed Nd: YAG Laser Cutting of Carbon Fibre Composite Materials CIRP Annals - Manufacturing Technology. 39, 179–182 (1990). https://doi.org/10.1016/S0007-8506(07)61030-0

Davim, J.P., Barricas, N., Conceicao, M., Oliveira, C.: Some experimental studies on CO2 laser cutting quality of polymeric materials. J Mater Process Technol. 198, 99–104 (2008a)

El Aoud B, Boujelbene M, Bayraktar E, Salem SB (2019) Optimization of kerf quality during CO 2 laser cutting of titanium alloy sheet Ti-6Al-4V and pure titanium Ti. In: mechanics of composite, hybrid and multifunctional materials, volume 5. Springer, pp 213-219

Herzog, D., Jaeschke, P., Meier, O., Haferkamp, H.: Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP International Journal of Machine Tools and Manufacture. 48, 1464–1473 (2008). https://doi.org/10.1016/j.ijmachtools.2008.04.007

Li, M., Li, S., Yang, X., Zhang, Y., Liang, Z.: Effect of lay-up configuration and processing parameters on surface quality during fiber laser cutting of CFRP laminates The International Journal of Advanced Manufacturing Technology. 100, 623–635 (2019)

Li, Z.L., Zheng, H.Y., Lim, G.C., Chu, P.L., Li, L.: Study on UV laser machining quality of carbon fibre reinforced composites Composites Part A: Applied Science and Manufacturing. 41, 1403–1408 (2010). https://doi.org/10.1016/j.compositesa.2010.05.017

Mathew, J., Goswami, G., Ramakrishnan, N., Naik, N.: Parametric studies on pulsed Nd: YAG laser cutting of carbon fibre reinforced plastic composites Journal of Materials Processing Technology. 89, 198–203 (1999a)

Mohamed, S.B., Ab Rashid, R., Muhamad, M., Ismail, J.: Composite Materials and Types of Machining, pp. 1–14. Down Milling Trimming Process Optimization for Carbon Fiber-Reinforced Plastic. Springer, In (2019)

Negarestani, R., Li, L., Sezer, H., Whitehead, D., Methven, J.: Nano-second pulsed DPSS Nd: YAG laser cutting of CFRP composites with mixed reactive and inert gases The International Journal of Advanced Manufacturing Technology. 49, 553–566 (2010)

Noskov, A., Thomassen, Y., Berlinger, B., Olsen, R., Ervik, T.K., Weinbruch, S.: Gilmutdinov A. Characterization of air contaminants emitted during laser cutting of carbon fiber-reinforced composite materials Analytical and bioanalytical chemistry. 411, 305–313 (2019)

Oh, S., Lee, I., Park, Y.-B., Ki, H.: Investigation of cut quality in fiber laser cutting of CFRP Optics & Laser Technology. 113, 129–140 (2019)

Rahimi, M.H., Shayganmanesh, M., Noorossana, R.: Pazhuheian F. Modelling and optimization of laser engraving qualitative characteristics of Al-SiC composite using response surface methodology and artificial neural networks Optics & Laser Technology. 112, 65–76 (2019)

Raza MS, Datta S, Bule B, Saha P (2019) Parametric study of laser cutting of carbon fibre reinforced polymer (CFRP) and the effect of fibre orientation on cutting quality Advances in Materials and Processing Technologies:1–11

Song H, Dan J, Du J, Ren G, Xiao J, Xu J (2019) Multiresponse Optimization for Laser-Assisted Machining of Fused Silica Using Response Surface Methodology Silicon:1–15

Zhang, Y., Li, J., Yang, R., Liu, T., Yan, Y.: Analysis of kerf quality on ultrafast laser cutting of anode material for lithium-ion battery Optics and Lasers in Engineering. 118, 14–21 (2019)

Dubey, A.K., Yadava, V.: Optimization of kerf quality during pulsed laser cutting of aluminium alloy sheet Journal of materials processing technology. 204, 412–418 (2008)

Yilbas, B.S., Shaukat, M.M., Ashraf, F.: Laser cutting of various materials: Kerf width size analysis and life cycle assessment of cutting process Optics & Laser Technology. 93, 67–73 (2017)

Tamrin, K., Nukman, Y., Choudhury, I., Shirley, S.: Multiple-objective optimization in precision laser cutting of different thermoplastics Optics and Lasers in Engineering. 67, 57–65 (2015)

ASTM D 3039/D 3039M,“Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials”. In: American Society for Testing and Materials, 1995

ASTM I (2007) Standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials ASTM D790–07

Box, G.E., Draper, N.R.: Empirical Model-Building and Response Surfaces. John Wiley & Sons (1987)

Robinson TJ (2007) Box–Behnken designs encyclopedia of statistics in quality and reliability

Bagci, E., Işik, B.: Investigation of surface roughness in turning unidirectional GFRP composites by using RS methodology and ANN International Journal of Advanced Manufacturing Technology. 31, 10–17 (2006). https://doi.org/10.1007/s00170-005-0175-x

Myers, R.H., Montgomery, D.C., Anderson-Cook, C.M.: Response Surface Methodology: Process and Product Optimization Using Designed Experiments (Wiley Series in Probability and Statistics). Wiley, New York (2009)

Shrivastava, Y., Singh, B.: Assessment of stable cutting zone in CNC turning based on empirical mode decomposition and genetic algorithm approach proceedings of the institution of mechanical engineers. Part C: Journal of Mechanical Engineering Science. 232, 3573–3594 (2018a)

Shrivastava, Y., Singh, B.: Estimation of stable cutting zone in turning based on empirical mode decomposition and statistical approach Journal of the Brazilian Society of Mechanical Sciences and Engineering. 40, 77 (2018b)

Singh, B., Nanda, B.: Slip damping mechanism in welded structures using response surface methodology Experimental mechanics. 52, 771–791 (2012)

Singh, B., Nanda, B.K.: Investigation into the effect of surface roughness on the damping of tack-welded structures using the response surface methodology approach Journal of Vibration and Control. 19, 547–559 (2013)

Acknowledgements

The Authors are thankful to Dr. B. N. Upadhyay, Research Scientist, Solid State laser division RRCAT, Indore, India for providing the experimental support.

Funding

This research has received no grant from any funding agency in any manner.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Declaration of Conflicting Interests

The authors declared no potential conflicts of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jain, A., Singh, B. Parametric Analysis during Laser Cutting of Basalt – Glass Hybrid Composite. Lasers Manuf. Mater. Process. 7, 111–139 (2020). https://doi.org/10.1007/s40516-019-00110-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-019-00110-1