Abstract

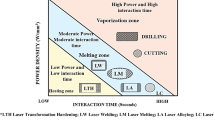

Wear is a restricting factor for steel in hostile environments but can be abated by laser cladding. Laser cladding of steel poses a promising solution to wear resistance. The high power direct diode laser is employed for the laser cladding of thicknesses of about 1.6 mm. Recently, the light rare earth metals have become important additions to smart materials, particularly Lanthanum oxide (La2O3) and Cerium Oxide (CeO2), to improve microhardness and wear resistance. Layers of Ni-WC with 1% and 2% La2O3 and CeO2 as alloying elements were cladded onto A36 steel substrate. The wear resistance and microstructure were studied with XRD and SEM. The hardness to modulus of elasticity ratio (H/E) was used to analyze the wear. It was found that the addition of 1% La2O3 or 1% CeO2 to Nickel-based alloy (40% Ni-60% WC) improves the wear resistance.

Similar content being viewed by others

References

Holmberg, K., Erdemir, A.: Influence of tribology on global energy consumption, costs, and emissions. Friction. 5(3), 263–284 (2017)

Oberle, T.L.: Properties influencing wear of metals. J Metals. 3(6), 438–439 (1951)

Kembaiyan, K.T., Keshavan, K.: Combating severe fluid erosion and corrosion of drill bits using thermal spray coating. Wear. 186-187, 487–492 (1995)

S. W. Huang, M. Samandia, M. Brandt. Abrasive wear performance and microstructure of laser clad WC/Ni layers. Wear (2004) 256 11–12 1095–1105

Rhys-Jones, T.N.: Thermally sprayed coating systems for surface protection and clearance control applications in aero engines. Surf Coat Technol. 43(44), 402–415 (1990)

Hardwicke, C.U., Lau, Y.-C.: Advances in thermal spray coatings for gas turbines and energy generation: a review. ASM International. 22(5), 564–576 (2013)

Ramakrishnan, N., Arunachalam, V.S.: Effective elastic moduli of porous ceramic materials. J. Am. Ceram. Soc. 76(11), 2745–2752 (1993)

Maiman, T.H.: Stimulated optical radiation in ruby. Essentials of Lasers 134–136 (1969)

Gnanamuthu, D.S.: Laser surface treatment. Opt Eng. 19(5), 783–792 (1980)

S.W. Huang, M. Samandia, M. Brandt. Abrasive wear performance and microstructure of laser clad WC/Ni layers. Wear (2004) 256 11–12 1095–1105

Chun Guo, Jianmin Chen, Jiansong Zhou. Effects of WC-Ni content on microstructure and wear resistance of laser cladding Ni-based alloys coating. Surf Coat Technol (2012) 206 8–9 2064–2071

Kennedy, E., Byrne, G., Collins, D.N.: A review of the use of high power diode lasers in surface hardening. J Mater Process Technol. 155-156, 1855–1860 (2004)

Jinhong Zhu, Lin Li, Zhu Liu. CO2 and diode laser welding of AZ31 magnesium alloy. Appl Surf Sci (2005) 247 1–4 300–306

Cui, C., Guo, Z., Liu, Y., Xie, Q., Wang, Z., Hu, J., Yao, Y.: Characteristics of cobalt-based alloy coating on tool steel prepared by powder feeding laser cladding. Opt Laser Technol. 39(8), 1544–1550 (2007)

M. Laribi, A. B Vannes, D. Treheux. Study of mechanical behavior of molybdenum coating using sliding wear and impact test. Wear (2007) 262 11–12 1330–1336

Chang, J.H., Chou, J.M., Hsieh, R.I., Lee, J.L.: Corrosion behavior of vacuum induction-melted Ni-based alloy in sulphuric acid. Corros Sci. 52(7), 2323–2330 (2010)

Qiwen, W., Mingxing, M., Cunyuan, P., Xiaohui, Y., Weiming, Z.: Corrosion resistance of laser produced in-situ particle reinforced Fe-matrix composite coating with high nickel content on spheroidal graphite cast iron. Phys Procedia. 41, 276–281 (2013)

Lima, R.S., Marple, B.R.: Thermal spray coatings engineered fro nanostructured ceramic agglomerated powders for structural, thermal barrier and biomedical applications. J Therm Spray Technol. 16(1), 40–63 (2007)

G. Balachandran. Extraction of Rare Earth for Advanced Application. Treatise on Process Metallurgy, Industrial Process (2014)

Ashassi-Sorkhabi, H., Moradi-Haghighi, M., Hosseini, M.G.: Effect of rare earth (Ce, La) compounds in the electroless bath on the plating rate, bath stability and microstructure of the nickel-phosphorous deposits. Surf Coat Technol. 202(9), 1615–1620 (2008)

Go, D., Shen, Y.: The role of La2O3 in direct laser sintering of submicrometre WC-Cop/cu MMCs. J Phys D Appl Phys. 41, 1–11 (2008)

Stefanov, P., Atanasova, G., Stoychev, D., Marinova, T.: Electrochemical Deposition of CeO2 on ZrO2 and Al2O3 Thin Films Formed on Stainless Steel. Surf Coat Technol. 180-181, 446–449 (2004)

K. L. Wang, Q. B. Zhang, M. L. Sun, X. G. Wei, Y. M. Zhu. Rare earth elements modification of laser-clad nickel-based alloy coatings. Appl Surf Sci (2001) 174 3–4 191–200

Wang, K.L., Zhang, Q.B., Sun, M.L., Wei, X.G., Zhu, Y.M.: Microstructure and corrosion resistance of laser clad coatings with rare earth elements. Corros Sci. 43(2), 255–267 (2001)

Surajit Purkayastha, D. K. Dwivedi. Effect of CeO2 on the Friction and Sliding Wear Performance of Ni/WC Coatings. International Conference on Advances in Electrical and Mechanical Engineering Phuket Thailand (2012) 18–19

de Carvalho Fernandes, S.M., Ramanathan, L.V.: Rare earth oxide coatings to decrease high temperature degradation of Chromia forming alloys. Mater Res. 7(1), 135–139 (2004)

William F. Smith. Structure and Properties of Engineering Alloys. McGraw-Hill Book Company (1981)

Farahmand, P., Frosell, T., McGregor, M., Kovacevic, R.: Comparative study of the slurry erosion behavior of laser cladded Ni-WC coating modified by nanocrystalline WC and La2O3. Int J Adv Manuf Technol. 79(9-12), 1607–1621 (2015)

Archard, J.F.: Elastic deformation and the laws of friction. Proceedings of the Royal Society of London. J Math Phys Sci. 243(1233), 195–205 (1957)

Antunes, P.V., Ramalho, A., Carrilho, E.V.P.: Mechanical and wear behaviors of nano and microfilled polymeric composite: effect of filler fraction and size. Mater Des. 61, 50–60 (2014)

F. P. Bowden, L. Leben. The nature of sliding and the analysis of friction. Proceedings of the royal society (1939) A 169 371–379

Negrea, A., Predoi, M.V.: The elastic contact of a sphere with an elastic half-space, a comparison between analytical and finite elements solutions. U P B Sci Bull. 74(4), 69–78 (2012)

A. Z. Szeri. Fluid Film Lubrication; Theory and Design. Cambridge University press (1998)

Weng, F., Yu, H., Chen, C., Dai, J.: Microstuctures and Wear Properties of Laser Cladding Co-Based Composite Coatings on Ti-6Al-4V. Mater Des. 80, 174–181 (2015)

Leyland, A., Matthews, A.: On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimized tribological behaviour. Wear. 246(1-2), 1–11 (2000)

Benea, L., Basa, S.-B., Danaila, E., Caron, N., Raquet, O., Ponthiaux, P., Celis, J.-P.: Fretting and wear behaviors of Ni/nano-WC composite coatings in dry and wet conditions. Mater Des. 65, 550–558 (2015)

Lima, M.M., Godoy, C., Modenesi, P.J., Avelar-Batista, J.C., Davidson, A.: A . Matthews. Coating fracture toughness determined by Vickers indentation: an important parameter in cavitation erosion resistance of WC-co thermally sprayed coatings. Surf Coat Technol. 177-178, 489–496 (2004)

Rebholz, C., Leyland, A., Schneider, J.M., Voevodin, A.A., Matthews, A.: Structure, hardness and mechanical properties of magnetron-sputtered titanium-aluminum boride films. Surf Coat Technol. 120-121, 412–417 (1999)

Wang, X., Zhang, M., Zou, Z., Qu, S.: Microstructure and Properties of Laser Clad TiC+NiCrBSi+Rare Earth Composite Coatings. Surface and Coatings Technology, vol. 161, pp. 195–199 (2002)

Yi, Y., Cho, P., Al Zaabi, A., Addad, Y., Jang, C.: Potentiodynamic polarization behavior of AISI type 316 stainless steel in NaCl solution. Corros Sci. 74, 92–97 (2013)

Sharma, S.P., Dwivedi, D.K., Jain, P.K.: Effect of La2O3 addition on the microstructure, hardness and abrasive ear behavior of flame sprayed Ni based coatings. Wear. 267(5-8), 853–859 (2009)

Jiang, X., Zhao, J., Jiang, X.: Correlation between hardness and elastic moduli of the covalent crystals. Comput Mater Sci. 50(7), 2287–2290 (2011)

Farahmand, P., Liu, S., Zhang, Z., Kovacevic, R.: Laser cladding assisted by induction heating of Ni-WC composite enhanced by nano-WC and La2O3. Ceram Int. 40(10), 15421–15438 (2014)

Thivillon, L., Bertrand, P., Laget, B., Smurov, I.: Potential of direct metal deposition technology for manufacturing thick functionally graded coatings and parts for reactors components. J Nucl Mater. 385(2), 236–241 (2009)

Chu, J.P., Rigsbee, J.M., Banas, G., Elsayed-Ali, H.E.: Laser-shock processing effects on surface microstructure and mechanical properties of low carbon steel. Mater Sci Eng. A260, 260–268 (1999)

Lin, D., Ye, C., Liao, Y., Suslov, S., Liu, R., Cheng, G.J.: Mechanism of fatigue performance enhancement in a laser sintered superhard nanoparticles reinforced nanocomposite followed by laser shock peening. J Appl Phys. 113(13), 133509 (2013)

Acknowledgments

This study was supported by the Research Center for Advanced Manufacturing (RCAM) at SMU. The authors gratefully appreciate the help of Andrzej Socha in performing the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohammed, S., Balu, P., Ahmed, A. et al. Improvement of Wear Resistance of the Nickel Based Alloy Mixed with Rare Earth Elements by High Power Direct Diode Laser Cladding. Lasers Manuf. Mater. Process. 6, 173–188 (2019). https://doi.org/10.1007/s40516-019-00087-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-019-00087-x