Abstract

In the nuclear industry, a critical welding process is joining of an end plate to a fuel rod to form a fuel bundle. Literature on zirconium welding in such a critical operation is limited. A CFD model is developed and performed for the three-dimensional non-linear thermo-fluid analysis incorporating buoyancy and Marnangoni stress and specifying temperature dependent properties to predict weld geometry and temperature field in and around the melt pool of laser spot during welding of a zirconium alloy E110 endplate with a fuel rod. Using this method, it is possible to estimate the weld pool dimensions for the specified laser power and laser-on-time. The temperature profiles will estimate the HAZ and microstructure. The adequacy of generic nature of the model is validated with existing experimental data.

Similar content being viewed by others

References

Svenungsson, J., Choquet, I., Kaplan, A.F.H.: Laser welding process – a review of keyhole welding modeling. Phys. Procedia. 78, 182–191 (2015)

Ai, Y., Wang, J., Jiang, P., Liu, Y., Liu, W.: Parameters optimization and objective trend analysis for fiber laser keyhole welding based on Taguchi – FEA. Int. J. Adv. Manuf. Technol. 90, 1419–1432 (2017)

Krishnan, R., Asundi, M.K.: Zirconium alloys in nuclear technology. Proc. Indian Acad. Sci. 4, 41–56 (1981)

R. Soni, P.N. Prasad, S. Vijayakumar, A.G. Chhatre and K.P. Dwivedi, “Fuel technology evolution for Indian PHWRs”, Nuclear Power Corporation of India Ltd., India. www.iaea.org/inis/collection/NCLCollectionStore/_Public/37/098/37098316.pdf

Kim, S.S., Lee, J.W., Park, G., Koh, J.H.: Development of zircaloy-endplate welding technology for a DUPIC fuel bundle assembly. J. Nucl. Sci. Technol. 46(2), 103–108 (2009)

Slobodyan, M.S.: Methods of creation of permanent zirconium alloy joints in Reactor Art: A Review. Tsvetnye Metally. 10, 91–98 (2016)

R. Terrence Webster, “Welding of zirconium alloys”, ASM Handbook: Welding, Brazing, and Soldering (Editors: D.L. Olson, T.A. Siewert, S. Liu, and G.R. Edwards), Volume 6, pp.787-788 (1993).

P. Rudling, A. Strasser and F. Garzarolli, “Welding of zirconium alloys’, Advanced Nuclear Technology International Krongjutarvagen 2C, SE-73 0 50 Skultuna. Sweden, (2007). https://www.antinternational.com/docs/samples/FM/11/First_chapter_-_ZIRAT12_STR_Welding_of_zirc_alloys.pdf

David, S.A., Deb Roy, T.: Current issues and problems in welding science. Science. 257, 497–502 (1992)

Deb Roy, T., David, S.A.: Physical processes in fusion welding. Rev. Mod. Phys. 67, 85–112 (1995)

Rosenthal, D.: The theory of moving sources of heat and its application to metal treatments. Trans ASME. 68, 849–866 (1946)

Lax, M.: Temperature rise induced by a laser beam. J. Appl. Phys. 48, 3919–3924 (1977)

Nissim, Y.I., Lietoila, A., Gold, R.B., Gibbons, J.F.: Temperature distributions produced in semiconductors by a scanning elliptical circular CW laser beam. J. Appl. Phys. 51, 274–279 (1980)

Steen, W.M., Dowden, J., Davis, M., Kapadia, P.: A point and line source model of laser keyhole welding. J. Phys. D. 21, 1255–1260 (1988)

Mackenzie, J.A., Robertson, M.L.: The numerical solution of one-dimensional phase change problems using an adaptive moving mesh method. J. Comput. Phys. 161, 537–557 (2000)

Wei, P.S., Yeh, J.S., Ting, C.N., Debroy, T., Chung, F.K., Lin, C.L.: The Effects of Prandtl Number on Wavy Weld Boundary. Int. J. Heat Mass Transf. 52, 3790–3798 (2009)

Du, H., Hu, L., Liu, J., Hu, X.: A study on the metal flow in full penetration laser beam welding for titanium alloy. Comput. Mater. Sci. 29, 419–427 (2004)

Cho, W., Na, S., Thomy, C., Vollertsen, F.: Numerical simulation of molten pool dynamics in high power disk laser welding. J. Mater. Process. Technol. 212, 262–275 (2012)

Robert, A., Debroy, T.: Geometry of laser spot welds from dimensionless numbers. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 32, 941–947 (2001)

X.H. Ye, and X. Chen, “Three-dimensional variable-property modeling of laser full-penetration welding characteristics”, Progress in Computational Fluid Dynamics, Vol. 2, pp. 106–113 (2002).

Sahin, S., Toparli, M., Ozdemir, I., Sasaki, S.: Modeled and measured residual stresses in a bi-material joint. J. Mater. Process. Technol. 132, 235–241 (2003)

Josefson, B.L.: Prediction of residual stresses and distortions in welded structures. Trans ASME J. Offshore Mech. Arct. Eng. 115, 52–57 (1993)

A.M. Kamara, W. Wang, S. Marimuthu, A.J. Pinkerton and L. Li, “Influence of melt pool convection on residual stress induced in laser cladding and powder deposition,” Proceeding of the 4th Pacific International Conference on Applications of Lasers and Optics (PICALO 2010), Paper No. 604 (2010).

S. Safdar, A.J. Pinkerton, R. Moat, L. Li, M.A. Sheikh, M. Preuss and P.J. Withers, “An anisotropic enhanced thermal conductivity approach for modelling laser melt pools,” Proceeding of the 26th International Congress on Applications of Lasers and Electro-Optics (ICALEO 2007), Paper No. 1305, pp. 665–673 (2007).

Marimuthu, S., Eghlio, R.M., Pinkerton, A.J., Li, L.: “Coupled computational fluid dynamic and finite element multiphase modeling of laser weld bead geometry formation and joint strengths”, Paper No: MANU-11-1292, Journal of Manufacturing Science and Engineering. Vol. 135, 011004 (2013). https://doi.org/10.1115/1.4023240

Goldak, J., Chakravarti, A., Bibby, M.: A new finite element model for welding heat sources. Metall. Trans. B. 15, 299–305 (1984)

Goldak, J., Bibby, M., Moore, J., House, R., Patel, B.: Computer modeling of heat flow in welds. Metall. Trans. B. 17, 587–600 (1986)

C.S. Wu, H.G. Wang and Y.M. Zhang, “A new heat source model for keyhole plasma arc welding in FEM analysis of the temperature profile”, Welding Journal, pp 284-291 (2006). files. aws.org/wj/supplement/wj1206-284.pdf

Fluent, ANSYS 16 V User’s Guide, ANSYS Inc.

Voller, V.R., Prakash, C.: A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 30, 1709–1719 (1987). https://doi.org/10.1016/0017-9310(87)90317-6

Brent, A.D., Voller, V.R., Reid, K.J.: Enthalpy –porosity technique for modeling convection-diffusion phange change: Application to the melting of a pure metal. Numer. Heat Transfer. 13, 297–318 (1988)

Jalali, A., Najafi, A.F.: Numerical modeling of the solidification phase change in a pipe and evaluation of the effect of boundary conditions. Journal of Thermal Science. 19, 419–424 (2010). https://doi.org/10.1007/s11630-010-0403-z

Frewin, M.R., Scott, D.A.: Finite element model of pulsed laser welding. Weld. J. 78, 15s–22s (1999)

T. A. Palmer, B. Wood, J. W. Elmer, C. Westrich, J. O. Milewski, M. Piltch, M. Barbe, R. Carpenter, “Characterization of Stainless Steel and Refractory Metal Welds Made Using a Diode-Pumped, Continuous Wave Nd: YAG Laser”, UCRL-ID-146005, U.S. Department of Energy, Lawrence Livermore National Laboratory, Livermore, CA (October 19, 2001) https://e-reports-ext.llnl.gov/pdf/244384.pdf

B.C. Wood, T.A. Palmer and J.W. Elmer, “Comparison between keyhole weld model and laser welding experiments”, UCRL-ID-150357, U.S. Department of Energy, Lawrence Livermore National Laboratory, Livermore (September 23, 2002). https://e-reports-ext.llnl.gov/pdf/245608.pdf

R. Rai, “Modeling of heat transfer and fluid flow in keyhole welding”, Ph. D. Thesis, The Pennsylvania State University (2008). https://etda.libraries.psu.edu/files/final_submissions/5347

Han, Q., Kim, D., Kim*, D., Lee, H., Kim, N.: Laser pulsed welding in thin sheets of Zircaloy-4. J. Mat. Process. Technol. 212, 1116–1122 (2012)

De, A., Maiti, S.K., Walsh, C.A., Bhadeshia, H.K.D.H.: Finite element simulation of laser spot welding. Sci. Technol. Weld. Join. 8(5), 377–384 (2003)

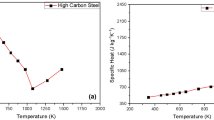

Paradis, P.-F., Rhim, W.-K.: Thermo-physical properties of zirconium at high temperature. J. Mater. Res. 14, 3713–3719 (1999). https://doi.org/10.1557/JMR.1999.0501

“Thermo-physical properties of materials for nuclear engineering: A tutorial and collection of data”, ISBN 978–92–0–106508–7, International Atomic Energy Agency, Vienna, (2008).

Sahiti, M., Raghavendra Reddy, M., Budi, J., Peter Praveen, J., Nageswara Rao, B.: Optimum WEDM process parameters of Incoloy®Alloy800 using Taguchi method. Int. J. Ind. Manuf. Syst. Eng. 1(3), 64–68 (2016)

Bharathi, P., Priyanka, T.G.L., Srinivasa Rao, G., Nageswara Rao, B.: Optimum WEDM process parameters of SS304 using Taguchi method. Int. J. Ind. Manuf. Syst. Eng. 1(3), 69–72 (2016)

Rajeev Kumar, D., Varma, P.S.S.K., Nageswara Rao, B.: Optimum drilling parameters of coir fiber-reinforced polyester composites. Am. J. Mech. Ind. Eng. 2(2), 92–97 (2017)

Konduri, S.S.S., Manideep Kumar Kalavala, V.D.S.R., Mandala, P., Manapragada, R.R., Nageswara Rao, B.: Application of Taguchi approach to seek optimum drilling parameters for woven fabric carbon fibre/epoxy laminates. MAYFEB J. Mech. Eng. 1, 29–37 (2017)

Dutta, O.Y., Nageswara Rao, B.: Investigations on the performance of chevron type plate heat exchangers. Heat Mass Transfer. https://doi.org/10.1007/s00231-017-2107-3

Acknowledgements

The authors would like to thank the reviewers for their valuable suggestions to improve the clarity of presentation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Satyanarayana, G., Narayana, K.L. & Boggarapu, N.R. Numerical Simulations on the Laser Spot Welding of Zirconium Alloy Endplate for Nuclear Fuel Bundle Assembly. Lasers Manuf. Mater. Process. 5, 53–70 (2018). https://doi.org/10.1007/s40516-018-0053-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40516-018-0053-7