Abstract

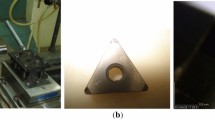

The importance of rapid tooling (RT) and additive manufacturing (AM) appears to be indispensable for boosting the process of manufacturing and expanding the horizon of production technology worldwide. This concept draws the attention of numerous scholars to arrive at a conclusive theory for the widespread utilization of RT. This study attempts to determine the viability and performance of an RT electrode in the field of electro discharge machining (EDM). The electrode prototype is made using an acrylonitrile butadiene styrene (ABS) plastic by fused deposition modeling (FDM), an AM technique, electroplated with copper of desired thickness, and used in die sinking EDM of D2 steel. The scanning electron microscope analysis of the electroplated samples confirms that it is possible to obtain the desired thickness of the metal by electroplating on any electrically conductive surface. In the present work, an experimental study is performed for examining the electroplated copper thickness of the plastic EDM electrode and its performances. It is found that the electroplated ABS plastic EDM RT electrode successfully performs the machining operation of D2 steel, and the results are comparable with a solid electrode. The study reveals that the RT electrode can be regarded as a viable tool for rough cutting or semi-finishing cut EDM functions. The experimental results are thoroughly discussed, examined, analyzed, and evaluated for the purpose of developing the appropriate form of the concept.

Similar content being viewed by others

References

Rao TB, Krishna AG, Katta RK et al (2015) Modeling and multi-response optimization of machining performance while turning hardened steel with self propelled rotary tool. Adv Manuf 3(1):84–95

Chu WS, Kim CS, Lee HT et al (2014) Hybrid manufacturing in micro/nano scale: a review. Int J Precis Eng Manuf-Green Technol 1(1):75–92

Iakymenko N, Alfnes E, Thomassen MK (2016) A differentiated approach for justification of advanced manufacturing technologies. Adv Manuf 4(3):257–267

Dimla DE, Hopkinson N, Rothe H (2004) Investigation of complex rapid EDM electrodes for rapid tooling applications. Int J Adv Manuf Technol 23(3–4):249–255

Hsu CY, Chen DY, Lai MY et al (2008) EDM electrode manufacturing using RP combining electroless plating with electroforming. Int J Adv Manuf Technol 38(9):915–924

Negi S, Dhiman S, Sharm RK (2013) Basics applications and future of additive manufacturing technologies: a review. J Manuf Technol Res 5(1–2):75–96

Monzon M, Benıtez AN, Marreroa MD et al (2008) Validation of electrical discharge machining electrodes made with rapid tooling technologies. J Mat Proc Technol 1196(1–3):109–114

Panda MC, Yadava V (2010) Thermal modelling of material removal rate and surface roughness in die sinking-electro chemical spark machining process. J Mach Form Technol 2(1–2):1–2

Pradhan MK, Das R, Biswas CK (2010) Prediction of surface roughness in electrical discharge machining of D2 steel using regression and artificial neural networks modeling. J Mach Form Technol 2(1–2):25–46

Gillot F, Mognola P, Furet B (2005) Dimensional accuracy studies of copper shells used for electro-discharge machining electrodes made with rapid prototyping and the electroforming process. J Mater Proc Technol 159(1):33–39

Arthur A, Dickens PM (1995) Rapid prototyping of EDM electrodes by stereolithography. In: International symposium on electro machining (ISEM) XI. Lausanne, Switzerland, pp 691–699

Naruskevicius L, Tamasiunaite LT, Zielieni A et al (2012) A Co-based surface activator for electroless copper deposition. Surf Coat Technol 206(11–12):2967–2971

Fritz N, Koo HC, Wilson Z et al (2012) Electroless deposition of copper on organic and inorganic substrates using a Sn/Ag catalyst. J Electrochem Soc 159(6):D386–D392

Wang GX, Li N, Hu HL et al (2006) Process of direct copper plating on ABS plastics. Appl Surf Sci 253(2):480–484

Yen PC (1995) Improved ABS plastic activating treatment for electroless copper plating. Polymer 36(17):3399–3400

Bazzaoui M, Martins JI, Bazzaoui EA et al (2013) A simple method for acrylonitrile butadiene styrene metallization. Surf Coat Technol 224(7):71–76

Li D, Goodwin K, Yang CL (2008) Electroless copper deposition on aluminum-seeded ABS plastics. J Mater Sci 43(22):7121–7131

Shu Z, Wang X (2012) Environment-friendly Pd free surface activation techniques for ABS surface. Appl Surf Sci 258(14):5328–5331

European Commission (2006) Integrated pollution prevention and control reference document on best available techniques for the surface treatment of metals and plastics

Liu ZC, He Q, Hou P et al (2005) Electroless plating of copper through successive pretreatment with silane and colloidal silver. Colloids Surf A Physicochem Eng Asp 257–258:283–286

Nair KM, Skurski MA, Voultos JD (2013) Nickel-gold plateable thick film silver paste. US Patent 8609256 B2, 17 December 2013

Ohno L (1991) Electrochemistry of electroless plating. Mater Sci Eng 146(1–2):33–49

Gan X, Zhou K, Hu W et al (2012) Role of additives in electroless copper plating using hypophosphite as reducing agent. Surf Coat Technol 206(15):3405–3409

Schlesinger M, Paunovic M (2011) Modern electroplating, 5th edn. Wiley, New Jersey

Vaskelis A, Jaciauskiene J, Stalnioniene I et al (2007) Accelerating effect of ammonia on electroless copper deposition in alkaline formal dehyde-containing solutions. J Electroanal Chem 600(1):6–12

Zhu Z, Zhu D, Qu NS (2008) Synthesis of smooth copper deposits by simultaneous electroforming and polishing process. Mater Lett 62(8–9):1283–1286

Jilani ST, Pandey PC (1984) Experimental investigations into the performance of water as dielectric in EDM. Int J Mach Tool Design Res 24:31–43

Chen SL, Yan BH, Huang FY (1999) Influence of kerosene and distilled water as dielectric on the electric discharge machining characteristics of Ti-6Al-4V. J Mater Proccess Technol 87:107–111

Syed KH, Palaniyandi K (2012) Performance of electrical discharge machining using aluminum powder suspended distilled water. Turk J Eng Environ Sci 36:195–207

Mathapathi U, Jeevraj S, Kumar S et al (2013) Analysis of material removal rate with powder mixed dielectric. IJCAE 4(3):316–332

Goyal S, Singh RK (2014) Parametric study of powder mixed EDM and optimization of MRR & surface roughness. Int J Sci Eng Technol 3(1):56–62

Padhi SK, Das HC, Mahapatra SS (2017) A review on experimental investigations on parametric appraisal in EDM process. J Adv Res Dyn Control Syst 13:594–603

Padhi SK, Sahu RK, Mahapatra SS et al (2017) Optimization of fused deposition modeling process parameters using a fuzzy inference system coupled with Taguchi philosophy. Adv Manuf 5:231–242

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Padhi, S.K., Mahapatra, S.S., Padhi, R. et al. Performance analysis of a thick copper-electroplated FDM ABS plastic rapid tool EDM electrode. Adv. Manuf. 6, 442–456 (2018). https://doi.org/10.1007/s40436-018-0238-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-018-0238-5