Abstract

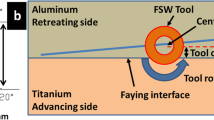

Dissimilar lap joints were produced by friction stir welding (FSW) out of Ti6Al4V titanium alloy and AA2024 aluminum alloy sheets. The joints, welded with varying tool rotation and feed rate, were studied by analyzing the maximum shear strength, Vickers microhardness and optical observations. A dedicated numerical model, able to take into account the presence of the two different alloys, was used to highlight the effects of the process parameters on temperature distribution, strain distribution, and material flow. The combined analysis of experimental measurements and numerical predictions allowed explaining the effects of tool rotation and feed rate on the material flow. It was found that tool rotation had a larger impact on the joint effectiveness with respect to feed rate. A competition between material mixing and heat input occurs with increasing tool rotation, resulting in higher joint strength when lower values of tool rotation are used.

Similar content being viewed by others

References

Leyens C, Kocian F, Hausmann J et al (2003) Materials and design concepts for high performance compressor components. Aerosp Sci Technol 7(3):201–210

Elias KL, Daehn GS, Brantley WA et al (2007) An initial study of diffusion bonds between superplastic Ti-6Al-4V for implant dentistry applications. J Prosthet Dent 97(6):357–365

Sujata M, Bhargava S, Sangal S (1997) On the formation of TiAl3 during reaction between solid Ti and liquid Al. J Mater Sci Lett 16(13):1175–1178

Wang GX, Dahms M, Leitner G et al (1994) Titanium aluminides from cold-extruded elemental powders with Al-contents of 25-75 at% Al. J Mater Sci 29(7):1847–1853

Wei Y, Li J, Xiong J et al (2012) Joining aluminum to titanium alloy by friction stir lap welding with cutting pin. Mater Charact 71:1–5

Dressler U, Biallas G, Alfaro MU (2009) Friction stir welding of titanium alloy TiAl6V4 to aluminium alloy AA2024-T3. Mater Sci Eng A 526(1–2):113–117

Wilden J, Bergmann JP (2004) Manufacturing of titanium/aluminium and titanium/steel joints by means of diffusion welding. Weld Cut 3(5):285–290

Yao W, Wu A, Zou G et al (2007) Structure and forming process of the Ti/Al diffusion bonding joints. Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met Mater Eng 36(4):700–704

Gao M, Chen C, Gu Y et al (2014) Microstructure and tensile behavior of laser arc hybrid welded dissimilar Al and Ti alloys. Materials 7(3):1590–1602

Elrefaey A, Tillmann W (2009) Solid state diffusion bonding of titanium to steel using a copper base alloy as interlayer. J Mater Process Technol 209(5):2746–2752

Kim YG, Fujii H, Tsumura T et al (2006) Three defect types in friction stir welding of aluminum die casting alloy. Mater Sci Eng A 415(1–2):250–254

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding: process, weldment structure and properties. Prog Mater Sci 53(6):980–1023

Khodir SA, Shibayanagi T (2008) Friction stir welding of dissimilar AA2024 and AA7075 aluminum alloys. Mater Sci Eng B: Solid-State Mater Adv Technol 148(1–3):82–87

Liu D, Xin R, Zheng X et al (2013) Microstructure and mechanical properties of friction stir welded dissimilar Mg alloys of ZK60-AZ31. Mater Sci Eng A 561:419–426

Li B, Zhang Z, Shen Y et al (2014) Dissimilar friction stir welding of Ti-6Al-4V alloy and aluminum alloy employing a modified butt joint configuration: influences of process variables on the weld interfaces and tensile properties. Mater Des 53:838–848

Wu A, Song Z, Nakata K et al (2015) Interface and properties of the friction stir welded joints of titanium alloy Ti6Al4V with aluminum alloy 6061. Mater Des 71:85–92

Zhang Z, Shen Y, Feng X et al (2016) Dissimilar fiction stir welding of titanium alloy and aluminum alloy employing a modified butt joint configuration. Hanjie Xuebao/Trans China Weld Inst 37(5):28–32

Chen YC, Nakata K (2009) Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater Des 30(3):469–474

Chen YH, Ni Q, Ke LM (2012) Interface characteristic of friction stir welding lap joints of Ti/Al dissimilar alloys. Trans Nonferrous Met Soc China (Engl Ed) 22(2):299–304

Chen ZW, Yazdanian S (2015) Microstructures in interface region and mechanical behaviours of friction stir lap Al6060 to Ti-6Al-4V welds. Mater Sci Eng A 634:37–45

Buffa G, Hua J, Shivpuri R, et al (2006) A continuum based FEM model for friction stir welding: model development. Mat Sci Eng A: Struct 419(1–2):389–396

Gök K, Aydin M (2013) Investigations of friction stir welding process using finite element method. Int J Adv Manuf Technol 68(1–4):775–780

Abbasi M, Bagheri B, Keivani R (2015) Thermal analysis of friction stir welding process and investigation into affective parameters using simulation. J Mech Sci Technol 29(2):861–866

Buffa G (2016) Joining Ti6Al4V and AISI 304 through friction stir welding of lap joints: experimental and numerical analysis. Int J Mater Form 9(1):59–70

Buffa G, Fratini L, Micari F et al (2012) On the choice of tool material in friction stir welding of titanium alloys. In: Transactions of the North American Manufacturing Research Institution of SME, pp 785–794

Buffa G, Ducato A, Fratini L (2013) FEM based prediction of phase transformations during friction stir welding of Ti6Al4V titanium alloy. Mater Sci Eng A 581:56–65

Buffa G, Ducato A, Fratini L (2013) Dissimilar material lap joints by friction stir welding of steel and titanium sheets: process modeling. In: AIP Conference Proceedings, pp 491–498

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buffa, G., De Lisi, M., Sciortino, E. et al. Dissimilar titanium/aluminum friction stir welding lap joints by experiments and numerical simulation. Adv. Manuf. 4, 287–295 (2016). https://doi.org/10.1007/s40436-016-0157-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-016-0157-2