Abstract

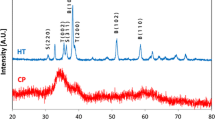

In this paper, the textured Si3N4 ceramics were prepared by adding seed particles during gel-casting in the magnetic field of 6 T, followed by pressureless sintering. The effect of pH on the stability and dispersibility of Si3N4 slurry and the effect of seed particles content on texture formation of Si3N4 ceramics were both studied. Those results showed that the slurry with good stability and dispersibility was obtained when pH was about 11.6. The a or b-axis of Si3N4 particles or crystals was aligned parallel to the direction of the magnetic field in the magnetic field of 6 T. The degree of texture of Si3N4 ceramics further increased during sintering. With the increasing of additional β-Si3N4 particles in the magnetic field of 6 T, the degree of texture increased from 0.19 without seed particles to 0.76 with 9% (mass fraction) seed particles. The increase of seed particles content promoted the texture formation of Si3N4 ceramics.

Similar content being viewed by others

References

Riley FL (2000) Silicon nitride and related materials. J Am Ceram Soc 83:245–265

Klemm H (2010) Silicon nitride for high-temperature applications. J Am Ceram Soc 93:1501–1522

Becher PF, Sun EY, Plucknett KP et al (1998) Microstructural design of silicon nitride with improved fracture toughness: I, effects of grain shape and size. J Am Ceram Soc 81:2821–2830

Zhu XW, Sakka Y (2009) Textured silicon nitride: processing and anisotropic properties. Sci Technol Adv Mater 9:033001

Kondo N, Suzuki Y, Miyajima T et al (2003) High-temperature mechanical properties of sinter-forgedsilicon nitride with ytterbia additive. J Eur Ceram Soc 23:809–815

Hirao K, Ohashi M, Brito ME et al (1995) Processing strategy for producing highly anisotropic silicon nitride. J Am Ceram Soc 78:1687–1690

Suzuki TS, Sakka Y, Kitazawa K (2001) Orientation amplification of alumina by colloidal filtration in a strong magnetic field and sintering. Adv Eng Mater 3:490–492

Sakka Y, Suzuki TS (2005) Textured development of feeble magnetic ceramics by colloidal procesing under high magnetic field. J Ceram Soc Jpn 113:26–36

Suzuki TS, Uchikoshi T, Sakka Y (2006) Control of texture in alumina by colloidal processing in a strong magnetic field. Sci Technol Adv Mater 7:356–364

Terada N, Suzuki HS, Suzuki TS et al (2009) Neutron diffraction texture analysis for alpha-Al2O3 oriented by high magnetic field and sintering. J Phys D 42:105404

Zhu XW, Suzuki TS, Uchikoshi T et al (2008) Highly texturing β-sialon via strong magnetic field alignment. J Am Ceram Soc 91:620–623

Zhu XW, Suzuki TS, Uchikoshi T et al (2008) Texturing behavior in sintered reaction-bonded silicon nitride via strong magnetic field alignment. J Eur Ceran Soc 28:929–934

Li SQ, Sassa K, Asai S (2004) Fabrication of textured Si3N4 ceramics by slip casting in a high magnetic field. J Am Ceram Soc 87:1384–1387

Li SQ, Sassa K, Asai S (2005) Textured crystal growth of Si3N4 ceramics in high magnetic field. Mater Lett 59:153–157

Zhu XW, Suzuki TS, Uchikoshi T et al (2006) Texture development in Si3N4 ceramics by magnetic field alignment during slip casting. J Ceram Soc Jpn 114:979–987

Zhu XW, Sakka Y, Suzuki TS et al (2010) The c-axis texturing of seeded Si3N4 with β-Si3N4 whiskers by slip casting in a rotating magnetic field. Acta Mater 58:146–161

Kokabi M, Babaluo AA, Baratua A (2006) Gelation process in low-toxic gelcasting systems. J Eur Ceram Soc 26:3083–3090

Yang JL, Dai CL, Huang Y (2005) Controllable forming technology in gel-casting. Mater Sci Forum 475–479:1325–1328

Wang XF, Wang RC, Peng CQ et al (2011) Thermo responsive gelcasting: improved drying of gelcast bodies. J Am Ceram Soc 94:1679–1682

Cai K, Huang Y, Yang J (2005) Alumina gelcasting by using HEMA system. J Eur Ceram Soc 25:1089–1093

Kaga H, Kinemuchi Y, Tanaka S et al (2006) Fabrication of c-axis oriented Zn0.98Al0.02O by a high-magnetic-field via gel-casting and its thermoelectric properties. J Ceram Soc Jpn 114:1085–1088

Chen WW, Kinemuchi Y, Tamura T et al (2007) Grain-oriented calcium hydroxyapatite ceramic and film prepared by magnetic alignment. Mater Lett 61:6–9

Oliveira MILL, Chen K, Ferreira JMF (2002) Influence of the deagglomeration procedure on aqueous dispersion, slip casting and sintering of Si3N4-based ceramics. J Eur Ceram Soc 22:1601–1607

Zhou LG, Huang Y, Xie ZP (2000) Gelcasting of concentrated aqueous silicon carbide suspension. J Eur Ceram Soc 20:85–90

Delgado AV, Gonzalez-Caballero F, Hunter RJ et al (2007) Measurement and interpretation of electrokinetic phenomena. J Colloid Interface Sci 309:194–224

Huang Y, Ma LG, Tang Q et al (2000) Surface oxidation to improve water-based gelcasting of silicon nitride. J Mater Sci 35:3519–3524

Li W, Chen P, Gu MY et al (2004) Effect of TMAH on rheological behavior of SiC aqueous suspension. J Euro Ceram Soc 24:3679–3684

Lotgering FK (1959) Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures: I. J Inorg Nucl Chem 9:113–123

Lee CJ, Chae JI, Kim DJ (2000) Effect of β-Si3N4 starting powder size on elongated grain growth in β-Si3N4 ceramics. J Eur Ceram Soc 20:2667–2671

Acknowledgements

This research work is supported by National Basic Research Program of China (Grant No. 2011CB610404), Shanghai Science and Technology Committee (Grant Nos. 09510700100, 135211011020, and 08DZ1130100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, ZG., Yu, JB., Li, CJ. et al. Effect of seed particles content on texture formation of Si3N4 ceramics by gel-casting in a strong magnetic field. Adv. Manuf. 3, 193–201 (2015). https://doi.org/10.1007/s40436-015-0106-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-015-0106-5