Abstract

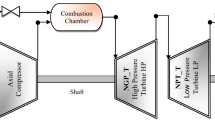

In practice, model-based fault diagnosis methods are essential to improve availability with reduced operating costs and good operational reliability of industrial systems. This is based firstly on the choice of the model identification method adapted to the system, depending on the complexity of the system and its interaction with its environment. Then, on the choice of an adequate diagnostic strategy for the generation of system failure indicators. In this work, the identification problem of the model variables of a double-shaft gas turbine is treated, to deal with the dynamics of model nonlinearities of this rotating machine. Hence, the equations which govern this turbine are carried out, using the local multi-models’ techniques with decoupled states, from the input/output measurements collected on the examined turbine. To best characterize their dynamic behavior in diverse operating areas. Subsequently, the resulting multi-model decoupled states are used to develop a fault diagnosis approach for this turbine. This makes it possible to generate symptoms of turbine failure from consistency tests between the measurements extracted on its real behavior, and the estimated signals which translate the reference behavior, given by the obtained multi-models. The obtained results in this work show the implementation efficiency of the proposed techniques of modeling and estimation of the examined decoupled turbine states, up to the phase of its implementation in the diagnostic strategy of the examined turbine based on the parity space approach.

Similar content being viewed by others

Abbreviations

- \(L\) :

-

Partition blocks

- \(\chi\) :

-

Coefficient of constriction

- \(\sigma\) :

-

Coefficient of dispersion

- \(c_{1}\) and \(c_{2}\) :

-

Acceleration coefficients

- \(w_{f}\) :

-

Fuel flow

- \(D\left( h \right)\) :

-

Research direction in parametric space

- \(\Delta\) :

-

Adjustment factor

- \(\mu_{i}\) :

-

Weighting function (activation)

- \(J\left( \theta \right)\) :

-

Objective cost minimization function

- \(\omega_{i}\) :

-

Weight functions

- \(G\) :

-

Gradient

- GT:

-

Gas Turbine

- h:

-

Iteration index

- \(H\left( \theta \right)\) :

-

Hessian

- HP:

-

High pressure

- \(\xi\) :

-

Function index

- \(\mu_{i}\) :

-

Index of weighting functions

- \(k\) :

-

Discrete time iteration index

- \(i\) :

-

Local model index

- \(j\) :

-

Multi-model output index

- Li:

-

Sub-models i (i = 2, 3, 4)

- LP:

-

Low pressure

- A, B, C & D:

-

State model matrix

- \(I\) :

-

Identity matrix

- \(A_{i}\), \(B_{i}\), \(C_{i,j}\) and \(D_{i,j}\) :

-

Matrices of decoupled state multi-models

- \(g(t)\) :

-

Best overall position

- MMA:

-

Multi model approach

- MOO:

-

Multi objective optimization

- N:

-

Number of measurements

- NGP:

-

High pressure turbine

- \(p\) :

-

Number of multi-model outputs

- NPT:

-

Low pressure turbine

- NSGA:

-

Non dominated sorting genetic algorithm

- \(L\) :

-

Parity space order

- \(\lambda\) :

-

Regularization parameter

- \(w\) :

-

Inertia weight

- \(x_{i} (t)\) :

-

Position of the particle

- PSO:

-

Particle Swarm Optimization

- \(y\) :

-

Model output

- \(\hat{y}\left( k \right)\) :

-

Estimated multi-model output

- \(y\left( k \right)\) :

-

Measured system output

- \(T_{7}\) :

-

Exhaust temperature

- \(T_{5}\) :

-

HP turbine temperature

- \(c_{i}\) :

-

Center variable

- \(r_{1}\), \(r_{2}\) :

-

Random variables

- \(u\) :

-

Control vector

- \(f(k)\) :

-

Fault vector

- \(\theta\) :

-

Parameter vector

- \(V_{s}\) :

-

Parity vector

- \(r(k)\) :

-

Residuals vector

- \(x\) :

-

State vector

- \(v_{i} (t)\) :

-

Particle speed

- \(N_{npt}\) :

-

LP turbine rotational speed

- \(N_{ngp}\) :

-

HP turbine rotation speed

References

Rahmoune MB, Hafaifa A, Kouzou A, Chen XiaoQi, Chaibet A (2021) Gas turbine monitoring using neural network dynamic nonlinear autoregressive with external exogenous input modelling. Math Comput Simul 179:23–47. https://doi.org/10.1016/j.matcom.2020.07.017

Kaino Y, Uchida M (2021) Parametric estimation for a parabolic linear SPDE model based on discrete observations. J Stat Plan Inference 211:190–220. https://doi.org/10.1016/j.jspi.2020.05.004

Hou G, Gong L, Huang C, Zhang J (2020) Fuzzy modeling and fast model predictive control of gas turbine system. Energy 200:117465. https://doi.org/10.1016/j.energy.2020.117465

Liu R, Pan T, Li Z (2017) Multi-model recursive identification for nonlinear systems with non-uniformly sampling. Clust Comput 20:25–32. https://doi.org/10.1007/s10586-016-0688-0

Zhou D, Huang D, Hao J, Hang Wu, Chang C, Zhang H (2021) Fault diagnosis of gas turbines with thermodynamic analysis restraining the interference of boundary conditions based on STN. Int J Mech Sci 191:106053. https://doi.org/10.1016/j.ijmecsci.2020.106053

Alblawi A (2020) Fault diagnosis of an industrial gas turbine based on the thermodynamic model coupled with a multi feedforward artificial neural networks. Energy Rep 6:1083–1096. https://doi.org/10.1016/j.egyr.2020.04.029

Zhou D, Wei T, Huang D, Li Y, Zhang H (2020) A gas path fault diagnostic model of gas turbines based on changes of blade profiles. Eng Fail Anal 109:104377. https://doi.org/10.1016/j.engfailanal.2020.104377

Li J, Ying Y (2020) Gas turbine gas path diagnosis under transient operating conditions: a steady state performance model based local optimization approach. Appl Therm Eng 170:115025. https://doi.org/10.1016/j.applthermaleng.2020.115025

Benyounes A, Hafaifa A, Guemana M (2016) Gas turbine modelling based on fuzzy clustering algorithm using experimental data. J Appl Artif Intell 30(1):29–51. https://doi.org/10.1080/08839514.2016.1138808

Mehrpanahi A, Payganeh G, Arbabtafti M (2017) Dynamic modeling of an industrial gas turbine in loading and unloading conditions using a gray box method. Energy 120:1012–1024. https://doi.org/10.1016/j.energy.2016.12.012

Hafaifa A, Belhadef R, Guemana M (2014) Modelling of surge phenomena in a centrifugal compressor: experimental analysis for control. Syst Sci Control Eng 2(1):632–641. https://doi.org/10.1080/21642583.2014.956269

Tosarkani BM, Amin SH (2020) A robust optimization model for designing a wastewater treatment network under uncertainty: multi-objective approach. Comput Ind Eng 146:106611. https://doi.org/10.1016/j.cie.2020.106611

Chen L, Huang B, Liu F (2014) Multi-model approach to nonlinear system identification with unknown time delay. IFAC Proc Vol 47(3):9388–9393. https://doi.org/10.3182/20140824-6-ZA-1003.00529

Hadroug N, Hafaifa A, Batel N, Abdellah K, Chaibet A (2018) Active fault tolerant control based on a neuro fuzzy inference system applied to a two shafts gas turbine. J Appl Artif Intell 32(6):515–540. https://doi.org/10.1080/08839514.2018.1483114

Hackney R, Nikolaidis T, Pellegrini A (2020) A method for modelling compressor bleed in gas turbine analysis software. Appl Therm Eng 172:115087. https://doi.org/10.1016/j.applthermaleng.2020.115087

Zribi A, Chtourou M, Djemel M (2017) Multiple model reduction approach using gap metric and stability margin for control nonlinear systems. Int J Control Autom Syst 15:267–273. https://doi.org/10.1007/s12555-015-0131-y

Nuerlan A, Wang P, Rizwan-uddin FZ (2020) A neural network based inverse system control strategy to decouple turbine power in multi-reactor and multi-turbine nuclear power plant. Prog Nucl Energy 129:103500. https://doi.org/10.1016/j.pnucene.2020.103500

Sanaye S, Hosseini S (2020) Prediction of blade life cycle for an industrial gas turbine at off-design conditions by applying thermodynamics, turbo-machinery and artificial neural network models. Energy Rep 6:1268–1285. https://doi.org/10.1016/j.egyr.2020.05.008

Chen S, Rui H (2018) A two-grid decoupled algorithm for fracture models. Comput Math Appl 76(5):1161–1173. https://doi.org/10.1016/j.camwa.2018.06.005

Nianci Lu, Pan L, Liu Z, Lee KY, Song Y, Si P (2020) Dynamic modeling of thermal-supply system for two-by-one combined-cycle gas and steam turbine unit. Fuel Process Technol 209:106549. https://doi.org/10.1016/j.fuproc.2020.106549

Liu X, Shi Y (2017) Daniela Constantinescu, Robust distributed model predictive control of constrained dynamically decoupled nonlinear systems: a contraction theory perspective. Syst Control Lett 105:84–91. https://doi.org/10.1016/j.sysconle.2017.05.004

Wiese AP, Blom MJ, Manzie C, Kitchener A (2015) Model reduction and MIMO model predictive control of gas turbine systems. Control Eng Pract 45:194–206. https://doi.org/10.1016/j.conengprac.2015.09.015

Yang XL, Hong Tao Wu, Chen B, Kang SZ, Cheng SL (2019) Dynamic modeling and decoupled control of a flexible Stewart platform for vibration isolation. J Sound Vib 439:398–412. https://doi.org/10.1016/j.jsv.2018.10.007

Li D, Guo W, Lerch A, Li Y, Wang L, Qidi Wu (2021) An adaptive particle swarm optimizer with decoupled exploration and exploitation for large scale optimization. Swarm Evol Comput 60:100789. https://doi.org/10.1016/j.swevo.2020.100789

Hafaifa A, Guemana M, Daoudi A (2015) Vibration supervision in gas turbine based on parity space approach to increasing efficiency. J Vib Control 21(8):1622–1632. https://doi.org/10.1177/1077546313499927

Afzal A, Ramis MK (2020) Multi-objective optimization of thermal performance in battery system using genetic and particle swarm algorithm combined with fuzzy logics. J Energy Storage 32:101815. https://doi.org/10.1016/j.est.2020.101815

Kaiping Qu, Zheng B, Tao Yu, Li H (2019) Convex decoupled-synergetic strategies for robust multi-objective power and gas flow considering power to gas. Energy 168:753–771. https://doi.org/10.1016/j.energy.2018.11.083

Hadroug N, Hafaifa A, Abdellah K, Chaibet A (2017) Dynamic model linearization of two shafts gas turbine via their input/output data around the equilibrium points. Energy 120:488–497. https://doi.org/10.1016/j.energy.2016.11.099

Mohseni SS, Yazdanpanah MJ, Noei AR (2017) Model order reduction of nonlinear models based on decoupled multi-model via trajectory piecewise linearization. Int J Control Autom Syst 15:2088–2098. https://doi.org/10.1007/s12555-016-0536-2

Duvall M, Riggs JB, Lee P (2001) Multi-model decoupled generic model control. Control Eng Pract 9(5):471–481. https://doi.org/10.1016/S0967-0661(01)00007-7

Touhidul SM, Mustafa JN, Ghysels G, Huysmans M (2020) Integrated bayesian multi-model approach to quantify input, parameter and conceptual model structure uncertainty in groundwater modeling. Environ Model Softw 126:104654. https://doi.org/10.1016/j.envsoft.2020.104654

Hou G, Gong L, Yang Z, Zhang J (2020) Multi-objective economic model predictive control for gas turbine system based on quantum simultaneous whale optimization algorithm. Energy Convers Manag 207:112498. https://doi.org/10.1016/j.enconman.2020.112498

Wang H, Xie L (2021) Fuzzy modeling of non-uniformly sampling nonlinear systems based on clustering method and convergence analysis. J Syst Sci Complex 34:502–519. https://doi.org/10.1007/s11424-020-9119-7

Zhang XW, Liu H, LiangPing Tu (2020) A modified particle swarm optimization for multimodal multi-objective optimization. Eng Appl Artif Intell 95:103905. https://doi.org/10.1016/j.engappai.2020.103905

Yuqiao Zheng Lu, Zhang YP, He Z (2020) Multi objective structural optimization of a wind turbine tower. J Shanghai Jiaotong Univ (Chin Ed) 25:538–544. https://doi.org/10.1007/s12204-020-2190-3

Tolouei H, Aliyari SM (2021) Nonlinear parity approach to fault detection in nonlinear systems using unknown input observer. Iran J Sci Technol Trans Electr Eng 45:321–333. https://doi.org/10.1007/s40998-020-00360-2

Nourani V, Elkiran G, Abdullahi J (2020) Multi-step ahead modeling of reference evapotranspiration using a multi-model approach. J Hydrol 581:124434. https://doi.org/10.1016/j.jhydrol.2019.124434

Huang D, Jianguo Xu, Chen R, Meng H (2020) Large eddy simulations of turbulent combustion of kerosene-air in a dual swirl gas turbine model combustor at high pressures. Fuel 282:11882015. https://doi.org/10.1016/j.fuel.2020.118820

Karimi MS, Raisee M, Salehi S, Hendrick P, Nourbakhsh A (2021) Robust optimization of the NASA C3X gas turbine vane under uncertain operational conditions. Int J Heat Mass Transf 164:120537. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120537

Wan X, Tong C, Meng S, Lan T (2020) Dynamic process monitoring based on a time-serial multi-block modeling approach. J Process Control 89:22–29. https://doi.org/10.1016/j.jprocont.2020.03.007

Chau TTT, Ailliot P, Monbet V (2021) An algorithm for non-parametric estimation in state–space models. Comput Stat Data Anal 153:107062. https://doi.org/10.1016/j.csda.2020.107062

Wang X, Zhang H, Bai S, Yue Y (2021) Design of agile satellite constellation based on hybrid-resampling particle swarm optimization method. Acta Astronaut 178:595–605. https://doi.org/10.1016/j.actaastro.2020.09.040

Xue Z, Li S (2005) Multi-model predictive control with local constraints based on model switching. J Control Theory Appl 3:150–156. https://doi.org/10.1007/s11768-005-0008-3

Nath AG, Udmale SS, Singh SK (2021) Role of artificial intelligence in rotor fault diagnosis: a comprehensive review. Artif Intell Rev 54:2609–2668. https://doi.org/10.1007/s10462-020-09910-w

Djeddi C, Hafaifa A, Iratni A, Hadroug N, Chen XiaoQi (2021) Robust diagnosis with high protection to gas turbine failures identification based on a fuzzy neuro inference monitoring approach. J Manuf Syst 59:190–213. https://doi.org/10.1016/j.jmsy.2021.02.012

Kang DW, Kim TS (2018) Model-based performance diagnostics of heavy-duty gas turbines using compressor map adaptation. Appl Energy 212:1345–1359. https://doi.org/10.1016/j.apenergy.2017.12.126

Farahi Moshir M, Ahmadi M, Dabir B (2021) Model-based water-flooding optimization using multi-objective approach for efficient reservoir management. J Pet Sci Eng 196:107988. https://doi.org/10.1016/j.petrol.2020.107988

Acknowledgements

This article is the result of a work on the identification of model variables of a twin-shaft gas turbine using the techniques of local decoupled state multi-models, for their use in the diagnosis of faults of this rotating machine with a parity space approach, based on the input/output measurements collected on the turbine under examination. This work is supported and carried out by the joint research team on gas turbines with the applied automation and industrial diagnosis laboratory, University of Djelfa, Algeria. However, the authors express their sincere thanks to the General Directorate of Scientific Research and Technological Development (DGRSDT), Algeria.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 Obtained gas turbine state model

The sub-models L2:

The sub-models L3:

The sub-models L4:

Rights and permissions

About this article

Cite this article

Aissat, S., Hafaifa, A., Iratni, A. et al. Exploitation of multi-models identification with decoupled states in twin shaft gas turbine variables for its diagnosis based on parity space approach. Int. J. Dynam. Control 10, 25–48 (2022). https://doi.org/10.1007/s40435-021-00804-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40435-021-00804-5