Abstract

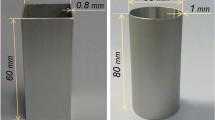

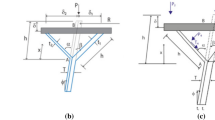

On the basis of the double-filled circular filled tube (DF-CFT), the sinusoidal corrugated curve is replaced by the circular curve, and the double-filled sinusoidal corrugated filled tube (DF-SCFT) is proposed. Firstly, the axial impact energy absorption characteristics of the circular tube, aluminum foam cylinder, and single-filled circular filled tubes (SF-CFT) were studied under a quasi-static compression experiment. The subsequent finite element model, created using the finite element software Abaqus/Explicit and Pro/Engineer, is verified for accuracy by Abaqus/Explicit. A crashworthiness analysis reveals that the DF-A5N5 (DF-SCFT with amplitude A of 5 mm and wave number N of 4) demonstrates improved energy absorption performance and interaction effects, with its specific energy absorption (SEA) being 13.92% higher than that of a DF-CFT. Then, the parameterization of the DF-SCFT is studied systematically. The structures investigated in this paper can serve as a reference for the innovative design of filling structures.

Similar content being viewed by others

References

Isaac CW, Ezekwem C (2021) A review of the crashworthiness performance of energy absorbing composite structure within the context of materials, manufacturing and maintenance for sustainability. Compos Struct 257:113081

Patel V, Tiwari G, Dumpala R (2020) Review of the crushing response of collapsible tubular structures. Front Mech Eng 15(3):438–474

Huang Z, Li Y, Zhang X, Chen W, Fang D (2021) A comparative study on the energy absorption mechanism of aluminum/CFRP hybrid beams under quasi-static and dynamic bending. Thin-Walled Structures 163:107772

Chen BC, Zou M, Liu GM, Song JF, Wang HX (2018) Experimental study on energy absorption of bionic tubes inspired by bamboo structures under axial crushing. Int J Impact Eng 115:48–57

Xu F, Zhang X, Zhang H (2018) A review on functionally graded structures and materials for energy absorption. Eng Struct 171:309–325

Abdullah NAZ, Sani MSM, Salwani MS, Husain NA (2020) A review on crashworthiness studies of crash box structure. Thin-Walled Structures 153:106795

Ha NS, Lu G (2020) A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos B Eng 181:107496

Bohara RP, Linforth S, Nguyen T, Ghazlan A, Ngo T (2023) Anti-blast and -impact performances of auxetic structures: a review of structures, materials, methods, and fabrications. Eng Struct 276:115377

Hatami H, Rad MS, Jahromi AG (2017) A theoretical analysis of the energy absorption response of expanded metal tubes under impact loads. Int J Impact Eng 109:224–239

Shams R, Niknejad A, Olabi AG, Nejad MZ (2019) Quasi-static flattening energy absorption process on preformed circular tubes by numerical and experimental analyses. Thin-Walled Structures 144:106260

Lagos M, Das R (2014) Analytical solution for the axisymmetric buckling of cylindrical shells. Int J Mech Mater Des 11(2):139–148

Lu B, Shen C, Zhang J, Zheng D, Zhang T (2021) Study on energy absorption performance of variable thickness CFRP/aluminum hybrid square tubes under axial loading. Compos Struct 276:114469

Ha NS, Pham TM, Hao H, Lu G (2021) Energy absorption characteristics of bio-inspired hierarchical multi-cell square tubes under axial crushing. Int J Mech Sci 201:106464

Xu X, Zhao Z, Zhou Z, Wang W, Tong Z, Lim CW (2020) Local surface nanocrystallization for buckling-resistant thin-walled structures. Int J Mech Mater Des 16(4):693–705

Huang Z, Zhang X (2020) Crashworthiness and optimization design of quadruple-cell aluminum/CFRP hybrid tubes under transverse bending. Compos Struct 235:111753

Sun F, Fan H (2017) Inward-contracted folding element for thin-walled triangular tubes. J Constr Steel Res 130:131–137

Praveen Kumar A, Yadi Reddy M, Shunmugasundaram M (2021) Energy absorption analysis of novel double section triangular tubes subjected to axial impact loading. Mater Today Proceed 47:5942–5945

Liu S, Tong Z, Tang Z, Liu Y, Zhang Z (2015) Bionic design modification of non-convex multi-corner thin-walled columns for improving energy absorption through adding bulkheads. Thin-Walled Struct 88:70–81

Tang Z, Liu S, Zhang Z (2012) Energy absorption properties of non-convex multi-corner thin-walled columns. Thin-Walled Struct 51:112–120

Xiao Y, Yin H, Fang H, Wen G (2016) Crashworthiness design of horsetail-bionic thin-walled structures under axial dynamic loading. Int J Mech Mater Des 12(4):563–576

Tarafdar A, Liaghat G, Ahmadi H, Razmkhah O, Chitsaz Charandabi S, Rezaei Faraz M, Pedram E (2021) Quasi-static and low-velocity impact behavior of the bio-inspired hybrid Al/GFRP sandwich tube with hierarchical core: Experimental and numerical investigation. Compos Struct 276:114567

Chen Y, Huang H, Deng X, Qin S (2023) Energy absorption characteristics analysis of multicellular columns based on the origami centripetal folding method. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2023.2204089

Ciampaglia A, Fiumarella D, Boursier Niutta C, Ciardiello R, Belingardi G (2023) Physics based data driven method for the crashworthiness design of origami composite tubes. Int J Mech Mater Des.

Deng Y, Li B, Huang Z, Lin Y, Li Y (2022) Experimental and numerical studies on the compression responses of novel mixed lattice structures. Mater Today Commun 33:104439

Yin H, Wen G (2011) Theoretical prediction and numerical simulation of honeycomb structures with various cell specifications under axial loading. Int J Mech Mater Des 7(4):253–263

Zhao C-Y, Liu H-T (2022) Multi-objective optimization of arc star honeycomb and bidirectional reentrant honeycomb using NSGA-II. Int J Mech Mater Des 19(2):375–389

Karimi M, Khoshgoftar MJ, Karimi M, Mirzaali MJ, Javanbakht Z (2023) An analytical model for the static behaviour of honeycomb sandwich plates with auxetic cores using higher-order shear deformation theories. Int J Mech Mater Des 19(4):951–969

Deng Y, Guo X, Lin Y, Huang Z, Li Y (2023) Dual-phase inspired soft electronic sensors with programmable and tunable mechanical properties. ACS Nano 17(7):6423–6434

Tan KH, Zhang YF (2010) Compressive stiffness and strength of concrete filled double skin (CHS inner & CHS outer) tubes. Int J Mech Mater Des 6(3):283–291

Zhang J, Du J, Guo H, Yuan H, Qin Q (2022) Splitting and curling performance of metal foam-filled circular tubes. Acta Mech 233(2):535–559

Yang X, Feng X, An T, Yang K, Sha J, Zhao N, Zong R (2022) Investigation on microstructures, compressive properties and energy absorption capacity of carbon nanotubes/aluminum composite foam-filled tubes. Compos Struct 282:115024

Czekanski A, Elbestawi MA, Meguid SA (2006) On the FE modeling of closed-cell aluminum foam. Int J Mech Mater Des 2(1–2):23–34

Zhou T, Zhang P, Xiao W, Liu J, Cheng Y (2019) Experimental investigation on the performance of PVC foam core sandwich panels under air blast loading. Compos Struct 226:111081

Linul E, Valean C, Linul PA (2018) Compressive behavior of aluminum microfibers reinforced semi-rigid polyurethane foams. Polymers (Basel) 10(12):1298

Garcia CD, Shahapurkar K, Doddamani M, Kumar GCM, Prabhakar P (2018) Effect of arctic environment on flexural behavior of fly ash cenosphere reinforced epoxy syntactic foams. Compos B Eng 151:265–273

Salehi M, Mirbagheri SMH, Jafari Ramiani A (2022) Experimental, theoretical, and numerical investigations into the compressive behavior of multi-layer metallic foam filled tubes. J Mater Eng Perform 31(5):3723–3740

Rogala M, Gajewski J, Gawdzińska K (2022) Crashworthiness analysis of thin-walled aluminum columns filled with aluminum–silicon carbide composite foam. Compos Struct 299:116102

Cui G, Meng L, Zhai X (2022) Buckling behaviors of aluminum foam-filled aluminum alloy composite columns under axial compression. Thin-Walled Struct 177:109399

Zhang Y, Wang G, Zhang Y, Ye J, Zeng T, Zhao K, Zheng Z, Wan R (2021) Crashworthiness design of car threshold based on aluminium foam sandwich structure. Int J Crashworthiness 27(4):1167–1178

Chilla V, Mondal DP, Ram GDJ, Mukherjee M (2022) Processing of in-situ aluminium foam-filled stainless steel tube with foam-tube bonding for enhanced crashworthiness. J Manuf Process 82:488–500

Yao R, Pang T, He S, Li Q, Zhang B, Sun G (2022) A bio-inspired foam-filled multi-cell structural configuration for energy absorption. Compos B Eng 238:109801

Zhang J, Du J, Miao F, Guo H (2022) Plastic behavior of slender circular metal foam-filled tubes under transverse loading. Thin-Walled Struct 171:108768

Wang Y, Zhang R, Liu S, Zhai X, Zhi X (2021) Energy absorption behaviour of an aluminium foam-filled circular-triangular nested tube energy absorber under impact loading. Structures 34:95–104

Wang G, Zhang Y, Zheng Z, Chen H, Yu J (2022) Crashworthiness design and impact tests of aluminum foam-filled crash boxes. Thin-Walled Struct 180:109937

Duarte I, Krstulović-Opara L, Dias-de-Oliveira J, Vesenjak M (2019) Axial crush performance of polymer-aluminium alloy hybrid foam filled tubes. Thin-Walled Struct 138:124–136

Salehi M, Mirbagheri SMH, Ramiani AJ (2021) Efficient energy absorption of functionally-graded metallic foam-filled tubes under impact loading. Trans Nonferrous Met Soc China 31(1):92–110

Li Z, Chen R, Lu F (2018) Comparative analysis of crashworthiness of empty and foam-filled thin-walled tubes. Thin-Walled Struct 124:343–349

Leveles B, Kemény A, Szijártó A (2021) Mechanical investigation of in-situ produced aluminium matrix syntactic foam-filled tubes. Mater Today Proceed 45:4221–4224

Albak Eİ (2021) Crashworthiness design for multi-cell circumferentially corrugated thin-walled tubes with sub-sections under multiple loading conditions. Thin-Walled Struct 164:107886

Li Z, Ma W, Yao S, Xu P (2021) Crashworthiness performance of corrugation- reinforced multicell tubular structures. Int J Mech Sci 190:106038

Deng X, Liu W, Jin L (2018) On the crashworthiness analysis and design of a lateral corrugated tube with a sinusoidal cross-section. Int J Mech Sci 141:330–340

Deng X, Liu W (2019) Experimental and numerical investigation of a novel sandwich sinusoidal lateral corrugated tubular structure under axial compression. Int J Mech Sci 151:274–287

Deng X, Liu W (2019) Multi-objective optimization of thin-walled sandwich tubes with lateral corrugated tubes in the middle for energy absorption. Thin-Walled Struct 137:303–317

Wu J, Zhang Y, Li J, Lai X, Duan N (2022) Energy absorption characteristics of nested corrugated-elliptical tubes subjected to a lateral crushing load. Compos Struct 297:115926

Li Z, Ma W, Hou L, Xu P, Yao S (2020) Crashworthiness analysis of corrugations reinforced multi-cell square tubes. Thin-Walled Struct 150:106708

Yao S, Yang Z, Li Z (2021) Crashworthiness study of double-layer sinusoidal tubes under axial loading. Int J Crashworthiness 27:1270–1286

Deng X, Qin S, Huang J (2021) Energy absorption characteristics of axially varying thickness lateral corrugated tubes under axial impact loading. Thin-Walled Struct 163:107721

Deng X, Qin S, Huang J (2021) Multiobjective optimization of axially varying thickness lateral corrugated tubes for energy absorption. Mech Adv Mater Struct 29(25):4259–4272

Liu W, Huang J, Deng X, Lin Z, Zhang L (2018) Crashworthiness analysis of cylindrical tubes filled with conventional and negative Poisson’s ratio foams. Thin-Walled Struct 131:297–308

Liu Y, Qi Y, Xu L, Han N, Zou M, Zhang Q (2022) Study on energy absorption behavior of bionic tube inspired by feather shaft of bean goose. Rendiconti Lincei. Scienze Fisiche e Naturali 33(2):363–374

Huo RY, Han D, Zhang Y, Jiang W, Fan LY, Peng XW, Shi GCJ, Chu MH, Zhang XY, Xie YM, Ren X (2023) Mechanical properties of auxetic circular and square tubes filled with aluminum foam. Eng Struct 281:115732

Xiang X, Zou S, Ha NS, Lu G, Kong I (2020) Energy absorption of bio-inspired multi-layered graded foam-filled structures under axial crushing. Compos B Eng 198:108216

Pirmohammad S, Saravani SA (2018) Crashworthiness performance of stiffened foam-filled tapered structures under axial and oblique dynamic loads. Latin Am J Sol Struct 15(5):e52

Zhang D, Fei Q, Liu J, Jiang D, Li Y (2020) Crushing of vertex-based hierarchical honeycombs with triangular substructures. Thin-Walled Struct 146:106436

Zheng G, Wu S, Sun G, Li G, Li Q (2014) Crushing analysis of foam-filled single and bitubal polygonal thin-walled tubes. Int J Mech Sci 87:226–240

Zhang J, Zheng D, Lu B, Zhang T (2021) Energy absorption performance of hybrid cross section tubes under oblique loads. Thin-Walled Struct 159:107133

Yao S, Chen Z, Xu P, Li Z, Zhao Z (2021) Experimental and numerical study on the energy absorption of polyurethane foam-filled metal/composite hybrid structures. Metals 11(1):118

Gao Z, Ruan D (2023) Axial crushing of novel hierarchical multi-cell square tubes. Eng Struct 286:116141

Song J, Xu S, Xu L, Zhou J, Zou M (2020) Experimental study on the crashworthiness of bio-inspired aluminum foam-filled tubes under axial compression loading. Thin-Walled Struct 155:106937

Zhang Z-J, Huang L, Li B-C, Chen T, Zhang Q-C, Jin F (2021) Design of a novel multi-walled tube-reinforced aluminum foam for energy absorption. Compos Struct 276:114584

Acknowledgements

This work is supported by National Natural Science Foundation of China (No. 52365036 and No. 52065059)

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deng, X., Yang, F. Energy absorption characteristics of a double-filled sinusoidal corrugated filled tube under axial impact. J Braz. Soc. Mech. Sci. Eng. 46, 364 (2024). https://doi.org/10.1007/s40430-024-04961-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-024-04961-4