Abstract

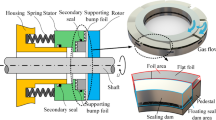

In order to improve the opening and stability of the Compliant Foil Face Gas Seal (CFFGS) under high-speed conditions, this paper proposes a new CFFGS structure with super-elliptical hole textures on the foil end face. It also establishes its theoretical model of aeroelastic coupling lubrication and solves the above model using the finite difference method, and an original binary representation method for the position of the hole texture arrangement scheme is proposed. Systematically investigated, the influence law of the hole texture arrangement scheme on the steady-state performance of the seal is identified, and its mechanism of influence is made clear. The optimized design of the structural parameters of the texture structure and the foil end face is further carried out under the optimal arrangement scheme of the hole texture with the maximum opening force and gas film stiffness as the target. The outcomes demonstrate that when the texture is set in the seal and face’s slope section, the seal’s opening and stability are obviously improved. Furthermore, within the scope of parameter research, when the super-elliptical coefficients n1 and n2 are 4, the transverse semi-axis a of super-elliptical texture is 2.5 mm, the longitudinal semi-axis b of super-elliptical texture is 4 mm, the wedge height δh is 14–20 μm, and the compliance coefficient α is 0.02–0.03, the CFFGS with super-elliptical hole texture has better all-around sealing performance.

Similar content being viewed by others

References

Bai L, Zhang P, Khan Z (2021) Semi salix leaf textured gas mechanical face seal with enhanced opening performance. Materials 14:7522

Lin Z, Yu L, Hua T et al (2022) Seal contact performance analysis of soft seals on high-pressure hydrogen charge valves. J Zhejiang Univ-Sci A (Appl Phys Eng) 23:247–256

Heshmat H (2003) Compliant foil seal. USP 6505837

Agrawal G, Patel K, Muson J et al (2007) Hydrodynamic foil face seal. USP 7261300

Munson J, Grant D, Agrawal G (2001) Foil face seal development. In: 37th joint propulsion conference and exhibit, p 3483

Salehi M, Heshmat H (2002) Evaluation of large compliant gas foil seals under engine simulated conditions. In: 38th AIAA/ASME/SAE/ASEE joint propulsion conference & exhibit, pp 7–10

Heshmat H, Walton J (2008) Innovative high-temperature compliant surface foil face seal development. In: 44th AIAA/ASME/SAE/ASEE joint propulsion conference & exhibit, p 4505

Chen Y, Chen K, Peng X et al (2022) Research on the operation mechanism and performance of bump-type compliant foil face gas seal. J Braz Soc Mech Sci Eng 44:325

Chen Y, Wang Q, Peng X et al (2022) Flow field and sealing performance analysis of compliant foil face gas seal. Adv Mech Eng 14:1–16

Wang Q, Chen Y, Peng X et al (2022) Analysis on dynamic characteristics of compliant foil face gas seals with three degrees of freedom perturbation. China Mech Eng 33:1828–1840

Chen Y, Xiong C, Peng X et al (2023) Performance of floating seal dam compliant foil face gas seal under different foil-dam positions. Tribology 43:481–491

Meng X, Bai S, Peng X (2014) An efficient adaptive finite element method algorithm with mass conservation for analysis of liquid face seals. J Zhejiang Univ-Sci A (Appl Phys Eng) 15:172–184

Wang S, Ding X, Ding J et al (2023) Numerical analysis on improving the rectangular texture floating ring gas-film seal characteristics with different bottom shapes. J Appl Fluid Mech 16:1371–1385

He Z, Zou Y, Wang Z et al (2024) Static characteristics analysis of radially misaligned textured gas foil journal bearing. Lubr Eng 49:15–23

Kaneko S (1989) Application of porous materials to annular plain seals: part 1—static characteristics. J Tribol 111:655–660

Etsion I, Burstein L (1996) A model for mechanical seals with regular microsurface structure. Tribol Trans 39:677–683

Etsion I, Kligerman Y, Halperin G (2008) Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol Trans 42:511–516

She B, Peng X, Meng X et al (2014) Comparison on seal performance of liquid-lubricated end face seals with different shapes inclined dimples. CIESC J 65:2202–2210

Yang X, Peng X, Meng X et al (2019) Thermo-elasto-hydrodynamic analysis of triangular textured mechanical face seals. J Zhejiang Univ-Sci A (Appl Phys Eng) 20:864–881

Feldman Y, Kligerman Y, Etsion I (2007) Stiffness and efficiency optimization of a hydrostatic laser surface textured gas seal. J Tribol 129:407–410

Bai S, Peng X, Li J et al (2011) Experimental study on hydrodynamic effect of orientation micro-pored surfaces. Sci China Technol Sci 54:659–662

Shi L, Zhang Y, Chen S et al (2019) Comparative research on gas seal performance textured with microgrooves and microdimples. J Braz Soc Mech Sci Eng 41:1–10

Chen Q (2017) Research on the elastohydrodynamic lubrication mechanism and characteristics of the gas foil bearing with texture surface. Dissertation, Harbin Institute of Technology

Zhang C (2021) Research on the lubrication mechanism and micro texture technology of aeroengine elastic gas foil bearing. Dissertation, Civil Aviation University of China

Chen Y, Jiang JB, Peng XD (2017) Dynamic characteristics and transient sealing performance analysis of hyperelliptic curve groove dry gas seals. Tribol Int 116:217–228

Kou G, Li X, Wang Y et al (2020) Steady performance and dynamic characteristics of a superellipse groove dry gas seal at a high-speed condition. Ind Lubr Tribol 72:789–796

Heshmat H, Walowit J, Pinkus O (1983) Analysis of gas-lubricated foil journal bearings. J Lubr Technol 105:647–655

Yan J, Liu Z, Wang Z et al (2017) Performance analysis of hydrodynamic gas foil thrust bearing based on Newton-Raphson iterative method. Turb Technol 59:116–120

Acknowledgments

The authors gratefully acknowledge the financial supports of the Key Program of the Natural Science Foundation of Zhejiang Province (LZ23E050002), the National Natural Science Foundation of China (51905513 and 52005470), and the Natural Science Foundation of Zhejiang Province (LQ21E050020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Daniel Onofre de Almeida Cruz.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Y., Zhang, J., Li, Y. et al. Design and performance optimization of texture arrangement scheme for foil face gas seal with super-elliptical hole texture. J Braz. Soc. Mech. Sci. Eng. 46, 362 (2024). https://doi.org/10.1007/s40430-024-04955-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-024-04955-2