Abstract

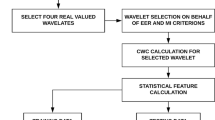

Vibration analysis plays a crucial role in fault and abnormality diagnosis in various mechanical systems. However, efficient vibration signal processing is required for valuable diagnosis and hidden patterns’ detection and identification. Hence, the present paper explores the application of a robust signal processing method called maximal overlap discrete wavelet packet transform (MODWPT) that supports multiresolution analysis, allowing for the examination of signal details at different scales. This capability is valuable for identifying faults that may manifest at different frequency ranges. MODWPT is combined with covariance and eigenvalues to signal reconstruction. After that, health indicators are specifically applied on the reconstructed vibration signal for feature extraction. The proposed approach was carried out on an experimental test rig where the obtained results demonstrate its effectiveness through confusion matrix analysis of machine learning tools. The ensemble tree model gives more accurate results (accuracy and stability) of bearing faults classification and efficiently identify potential failures and anomalies in mechanical equipment.

Similar content being viewed by others

References

LaCava W, Xing Y, Marks C et al (2013) Three-dimensional bearing load share behavior in the planetary stage of a wind turbine gearbox. IET Renew Power Gen 7:359–369

Wang J, Peng Y, Qiao W (2016) Current-aided order tracking of vibration signals for bearing fault diagnosis of direct-drive wind turbines. IEEE Trans Ind Electron 63:6336–6346

Li X, Elasha F, Shanbr S et al (2019) Remaining useful life prediction of rolling element bearings using supervised machine learning. Energies 12:2705

Tama BA, Vania M, Lee S, Lim S (2023) Recent advances in the application of deep learning for fault diagnosis of rotating machinery using vibration signals. Artif Intell Rev 56(5):4667–4709

Touzout W, Benazzouz D, Gougam F, Afia A, Rahmoune C (2020) Hybridization of time synchronous averaging, singular value decomposition, and adaptive neuro fuzzy inference system for multi-fault bearing diagnosis. Adv Mech Eng 12(12):1687814020980569

Afia A, Gougam F, Rahmoune C, Touzout W, Ouelmokhtar H, Benazzouz D (2023) Intelligent fault classification of air compressors using Harris Hawks optimization and machine learning algorithms. Trans Inst Meas Control 46:01423312231174939

Gougam F, Rahmoune C, Benazzouz D, Varnier C, Nicod JM (2020) Health monitoring approach of bearing: application of adaptive neuro fuzzy inference system (ANFIS) for RUL-estimation and Autogram analysis for fault-localization. In: 2020 prognostics and health management conference (PHM-Besançon). IEEE. p 200–206

Li L, Cai H, Han H, Jiang Q, Ji H (2020) Adaptive short-time fourier transform and synchrosqueezing transform for non-stationary signal separation. Signal Process 166:107231

Akujuobi CM (2022) Wavelets and wavelet transform systems and their applications. Springer International Publishing, Berlin/Heidelberg, Germany

Yu X, Liang Z, Wang Y, Yin H, Liu X, Yu W, Huang Y (2022) A wavelet packet transform-based deep feature transfer learning method for bearing fault diagnosis under different working conditions. Measurement 201:111597

Afia A, Gougam F, Rahmoune C, Touzout W, Ouelmokhtar H, Benazzouz D (2023) Gearbox fault diagnosis using REMD EO and machine learning classifiers. J Vib Eng Technol. https://doi.org/10.1007/s42417-023-01144-8

Afia A, Rahmoune C, Benazzouz D (2020) An early gear fault diagnosis method based on RLMD, Hilbert transform and cepstrum analysis. Mechatron Syst Control 49:115–123

Gougam F, Rahmoune C, Benazzouz D, Merainani B (2019) Bearing fault diagnosis based on feature extraction of empirical wavelet transform (EWT) and fuzzy logic system (FLS) under variable operating conditions. J Vibroeng 21(6):1636–1650

Shanbr S, Elasha F, Elforjani M et al (2018) Detection of natural crack in wind turbine gearbox. Renew Energy 118:172–179

Rahmoune C, Benazzouz D (2013) Monitoring gear fault by using motor current signature analysis and fast Kurtogram method. Int Rev Electr Eng 8:616–625

Afia A, Rahmoune C, Benazzouz D, Merainani B, Fedala S (2021) New gear fault diagnosis method based on MODWPT and neural network for feature extraction and classification. J Test Eval 49(2):1064–1085

Soualhi M, Nguyen KT, Soualhi A, Medjaher K, Hemsas KE (2019) Health monitoring of bearing and gear faults by using a new health indicator extracted from current signals. Measurement 141:37–51

Soualhi M, Nguyen KT, Medjaher K (2020) Pattern recognition method of fault diagnostics based on a new health indicator for smart manufacturing. Mech Syst Signal Process 142:106680

Soualhi A, Medjaher K, Zerhouni N (2014) Bearing health monitoring based on Hilbert–Huang transform, support vector machine, and regression. IEEE Trans Instrum Meas 64(1):52–62

Gougam F, Rahmoune C, Benazzouz D, Afia A, Zair M (2020) Bearing faults classification under various operation modes using time domain features, singular value decomposition, and fuzzy logic system. Adv Mech Eng 12(10):1687814020967874

Moshrefzadeh A, Fasana A (2018) The autogram: an effective approach for selecting the optimal demodulation band in rolling element bearings diagnosis. Mech Syst Signal Process 105:294–318

Afia A, Rahmoune C, Benazzouz D (2018) Gear fault diagnosis using autogram analysis. Adv Mech Eng 10(12):1687814018812534

Soualhi A, Clerc G, Razik H (2012) Detection and diagnosis of faults in induction motor using an improved artificial ant clustering technique. IEEE Trans Industr Electron 60(9):4053–4062

Benaggoune K, Yue M, Jemei S, Zerhouni N (2022) A data-driven method for multi-step-ahead prediction and long-term prognostics of proton exchange membrane fuel cell. Appl Energy 313:118835

Benaggoune K, Meraghni S, Ma J, Mouss LH, Zerhouni N (2020) Post prognostic decision for predictive maintenance planning with remaining useful life uncertainty. In: 2020 prognostics and health management conference (phm-besançon). IEEE. p 194–199

Gougam F, Chemseddine R, Benazzouz D, Benaggoune K, Zerhouni N (2021) Fault prognostics of rolling element bearing based on feature extraction and supervised machine learning: application to shaft wind turbine gearbox using vibration signal. Proc Inst Mech Eng C J Mech Eng Sci 235(20):5186–5197

Afia A, Rahmoune C, Benazzouz D, Merainani B, Fedala S (2020) New intelligent gear fault diagnosis method based on AUTOGRAM and radial basis function neural network. Adv Mech Eng 12(5):1687814020916593

Afia A, Hand O, Fawzi G et al. (2022) Gear fault detection, identification and classification using MLP neural network. In: Recent advances in structural health monitoring and engineering structures: Select proceedings of SHM and ES 2022. Springer, Singapore. p 221–234

Afia A, Gougam F, Rahmoune C, Touzout W, Ouelmokhtar H, Benazzouz D (2023) Spectral proper orthogonal decomposition and machine learning algorithms for bearing fault diagnosis. J Braz Soc Mech Sci En. https://doi.org/10.1007/s40430-023-04451-z

Li X, Yang Y, Hu N, Cheng Z, Shao H, Cheng J (2022) Maximum margin Riemannian manifold-based hyperdisk for fault diagnosis of roller bearing with multi-channel fusion covariance matrix. Adv Eng Inform 51:101513

Lai Y, Li R, Zhang Y, Meng L, Chen R (2023) Fault detection of reciprocating plunger pump with fault-free data based on unsupervised feature encoder and minimum covariance determinant. Meas Sci Technol. https://doi.org/10.1088/1361-6501/acde97

Wang N, Jia L, Qin Y, Li Z, Miao B, Geng J, Wang Z (2023) Scale-independent shrinkage broad learning system for wheelset bearing anomaly detection under variable conditions. Mech Syst Signal Process 200:110653

You K, Qiu G, Gu Y (2023) An efficient lightweight neural network using BiLSTM-SCN-CBAM with PCA-ICEEMDAN for diagnosing rolling bearing faults. Meas Sci Technol 34(9):094001

Jin Z, He D, Ma R, Zou X, Chen Y, Shan S (2022) Fault diagnosis of train rotating parts based on multi-objective VMD optimization and ensemble learning. Digit Signal Process 121:103312

Zhong X, Ban H (2022) Crack fault diagnosis of rotating machine in nuclear power plant based on ensemble learning. Ann Nucl Energy 168:108909

Cheng J, Sun J, Yao K, Xu M, Wang S, Fu L (2022) Development of multi-disturbance bagging Extreme Learning Machine method for cadmium content prediction of rape leaf using hyperspectral imaging technology. Spectrochim Acta Part A Mol Biomol Spectrosc 279:121479

Charbuty B, Abdulazeez A (2021) Classification based on decision tree algorithm for machine learning. J Appl Sci Technol Trends 2(01):20–28

Aravinth S, Sugumaran V (2018) Air compressor fault diagnosis through statistical feature extraction and random forest classifier. Prog Ind Ecol, Int J 12(1–2):192–205

Benkercha R, Moulahoum S (2018) Fault detection and diagnosis based on C4.5 decision tree algorithm for grid connected PV system. Sol Energy 173:610–634

Breiman L (2001) Random forests. Mach Learn 45:5–32

Pal M (2005) Random forest classifier for remote sensing classification. Int J Remote Sens 26(1):217–222

Zhou L, Wang Q, Fujita H (2017) One versus one multi-class classification fusion using optimizing decision directed acyclic graph for predicting listing status of companies. Inf Fusion 36:80–89

Gougam F, Rahmoune C, Benazzouz D, Zair MI, Afia A (2018) Early bearing fault detection under different working conditions using singular value decomposition (SVD) and adaptatif neuro fuzzy inference system (ANFIS). In: International conference on advanced mechanics and renewable energy (ICAMRE). p 28–29

Abellán J (2013) Ensembles of decision trees based on imprecise probabilities and uncertainty measures. Inf Fus 14(4):423–430

Achirul Nanda M, Boro Seminar K, Nandika D, Maddu A (2018) A comparison study of kernel functions in the support vector machine and its application for termite detection. Information 9(1):5

Guo Y, Zhang Z, Tang F (2021) Feature selection with kernelized multi-class support vector machine. Pattern Recogn 117:107988

Soualhi M, Soualhi A, Nguyen T-P, Medjaher K, Clerc G, Razik H (2023) LASPI: Détection et diagnostic des défauts de boîte de vitesses. LASPI. https://doi.org/10.25666/DATAUBFC-2023-03-06

“fitctree” [online] Available at: https://www.mathworks.com/help/stats/fitctree.html (Accessed 5 Oct 2019)

“fitcecoc” [online] Available at: https://www.mathworks.com/help/stats/fitcecoc.html [Accessed 5 Oct 2019)

“fitcensemble” [online] Available at: https://www.mathworks.com/help/stats/fitcensemble.html (Accessed 5 Oct 2019)

Dirvanauskas D, Maskeliunas R, Raudonis V, Damasevicius R (2019) Embryo development stage prediction algorithm for automated time lapse incubators. Comput Methods Programs Biomed 177:161–174

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Marcelo Areias Trindade.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gougam, F., Afia, A., Soualhi, A. et al. Bearing faults classification using a new approach of signal processing combined with machine learning algorithms. J Braz. Soc. Mech. Sci. Eng. 46, 65 (2024). https://doi.org/10.1007/s40430-023-04645-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04645-5