Abstract

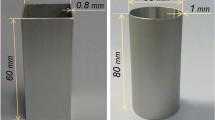

Improving the crashworthiness performance of the energy absorber and reducing the intensity of the load on the main structure using plastic deformation at the end of the vehicle is of vital significance. The primary objective of this research is to investigate the crashworthiness characteristics of multi-segmented conical tubes subjected to axial and oblique loads. Multi-segmented tubes can exhibit a superior design compared to simple ones. They reduce the initial peak load with different wall lengths and thicknesses. The specimens were designed by changing the number of segments, the arrangement of the segments, and changing geometrical dimensions of segments. A total of five different arrangements were designed in two groups: empty and foam-filled specimens, and crashworthiness parameters were extracted for them. The nonlinear finite element simulation method was established with the software ABAQUS, and their results were validated by experimental tests. Several absorbent design parameters were investigated, including energy absorption, initial peak load, and specific energy absorption, and it was found that the performance of all specimens was relatively acceptable. The overall results of this study showed that the proposed end-capped multi-segmented conical tubes filled with foam are considerable energy-absorbing structures in the axial and oblique directions. In addition, the initial peak load can be reduced with an increase in the number of segments.

Similar content being viewed by others

References

Magliaro J, Altenhof W, Alpas AT (2022) A review of advanced materials, structures and deformation modes for adaptive energy dissipation and structural crashworthiness. Thin Walled Struct 180:109808

Morello L, Rossini LR, Pia G, Tonoli A (2011) The automotive body: volume i: components design. Springer

Sharifi S, Shakeri M, Fakhari HE, Bodaghi M (2015) Experimental investigation of bitubal circular energy absorbers under quasi-static axial load. Thin Walled Struct 89:42–53

Luo X, Xu J, Zhu J, Gao Y, Nie L, Li W (2015) A new method to investigate the energy absorption characteristics of thin-walled metal circular tube using finite element analysis. Thin Walled Struct 95:24–30

Thinvongpituk C, Onsaloong N, Poonaya S (2016) Crush characteristic of foam-filled circular steel and aluminum tubes under axial loading. In: Proceedings of the world congress on engineering, vol 2

Beng YK, Dalimin MN, Wahab MA, Lai H (2018) Plastic collapse and energy absorption of empty circular aluminum tube under transverse quasi-static loading. J Mech Sci Technol 32(8):3611–3616

Ghasemi A, Shakeri M, Vanini SAS (2020) A multi-objective optimization of energy absorption properties of thin-walled circular tube with combined bar extrusion under quasi-static axial loading: Experiments and numerical simulation. Int J Mech Sci 180:105691

Patel V, Kalantre SS, Tiwari G, Dumpala R (2021) Crushing behavior of thick circular high strength aluminum tube against quasi-static axial loading. In: Adv Mech Eng. Springer, pp 551–557

Lu B, Shen C, Zhang J, Zheng D, Li Z (2020) Energy absorption analysis of square-circle hybrid section tubes under axial loading. Int J Crashworthiness, pp 1–16

Zhang J, Lu B, Zheng D, Li Z (2020) Experimental and numerical study on energy absorption performance of CFRP/aluminum hybrid square tubes under axial loading. Thin Walled Struct 155:106948

Rahi A (2018) Controlling energy absorption capacity of combined bitubular tubes under axial loading. Thin Walled Struct 123:222–231

Li Z, Rakheja S, Shangguan W-B (2019) Study on crushing behaviors of foam-filled thin-walled square tubes with different types and number of initiators under multiple angle loads. Thin Walled Struct 145:106376

Li Z, Chen R, Lu F (2018) Comparative analysis of crashworthiness of empty and foam-filled thin-walled tubes. Thin Walled Struct 124:343–349

Yu X et al (2018) Crushing and energy absorption of density-graded foam-filled square columns: experimental and theoretical investigations. Compos Struct 201:423–433

Zou X, Gao G, Dong H, Xie S, Chen G, Tan T (2017) Crashworthiness analysis and structural optimisation of multi-cell square tubes under axial and oblique loads. Int J Crashworthiness 22(2):129–147

Lu R, Liu X, Chen S, Hu X, Liu L (2017) Axial crashing analysis for tailor rolled square tubes with axially graded both wall thickness and material strength. Thin Walled Struct 117:10–24

Wang G, Zhang Y, Zheng Z, Chen H, Yu J (2022) Crashworthiness design and impact tests of aluminum foam-filled crash boxes. Thin Walled Struct 180:109937

Rogala M, Gajewski J, Gawdzińska K (2022) Crashworthiness analysis of thin-walled aluminum columns filled with aluminum–silicon carbide composite foam. Comp Struct 299:116102

Zhang J, Du J, Guo H, Yuan H, Qin Q (2022) Splitting and curling performance of metal foam-filled circular tubes. Acta Mech 233(2):535–559

Attar AA, Kazemi M (2022) Novel geometric arrangement effects on energy absorption of a conical structure with various cross-sections. Thin Walled Struct 173:109005

Akhavan Attar A, Kazemi M (2020) Investigation on crushing behavior of laminated conical absorbers with different arrangements under axial loading. Proc Inst Mech Eng Part L J Mater Des Appl 234(3):394–407

Kazemi M, Serpoush J (2021) Energy absorption parameters of multi-cell thin-walled structure with various thicknesses under lateral loading. Proc Inst Mech Eng Part L J Mater Des Appl 235(3):513–526

Kazemi M (2022) Experimental investigation on the energy absorption characteristics of sandwich panels with layering of foam core under quasi-static punch loading. Mech Adv Mater Struct 29(21):3067–3075

Alavi Nia A, Haddad Hamedani J (2010) Comparative analysis of energy absorption and deformations of thin walled tubes with various section geometries. ThinWalled Struct 48(12):946–954

Liu W, Jin L, Luo Y, Deng X (2020) Multi-objective crashworthiness optimisation of tapered star-shaped tubes under oblique impact. Int J Crashworthiness 26(3):328–342

Mirfendereski L, Salimi M, Ziaei-Rad S (2008) Parametric study and numerical analysis of empty and foam-filled thin-walled tubes under static and dynamic loadings. Int J Mech Sci 50(6):1042–1057

Ahmad Z, Thambiratnam D, Tan A (2010) Dynamic energy absorption characteristics of foam-filled conical tubes under oblique impact loading. Int J Impact Eng 37(5):475–488

Ahmad Z, Thambiratnam D (2009) Crushing response of foam-filled conical tubes under quasi-static axial loading. Mater Des 30(7):2393–2403

Ahmad Z, Thambiratnam DP (2009) Application of foam-filled conical tubes in enhancing the crashworthiness performance of vehicle protective structures. Int J Crashworthiness 14(4):349–363

Qi C, Yang S, Dong F (2012) Crushing analysis and multiobjective crashworthiness optimization of tapered square tubes under oblique impact loading. Thin Walled Struct 59:103–119

Azarakhsh S, Ghamarian A (2017) Collapse behavior of thin-walled conical tube clamped at both ends subjected to axial and oblique loads. Thin Walled Struct 112:1–11

Azimi MB, Asgari M (2016) A new bi-tubular conical–circular structure for improving crushing behavior under axial and oblique impacts. Int J Mech Sci 105:253–265

Sadighi A, Mahbod M, Asgari M (2020) Bi-tubular corrugated composite conical–cylindrical tube for energy absorption in axial and oblique loading: analysis and optimization. J Compos Mater 54(18):2399–2432

Rezvani MJ, Jahan A (2015) Effect of initiator, design, and material on crashworthiness performance of thin-walled cylindrical tubes: a primary multi-criteria analysis in lightweight design. Thin Walled Struct 96:169–182

Razazan M, Rezvani M, Souzangarzadeh H (2018) Evaluation of the performance of initiator on energy absorption of foam-filled rectangular tubes: experimental and numerical assessment. Exp Tech 42(2):129–139

Jiang H, Ren Y, Zheng J (2020) Gradient-degraded material-induced trigger to improve crashworthiness of composite tubes in a controlled manner. J Reinf Plast Compos 39(1–2):60–77

Rezvani MJ, Souzangarzadeh H (2020) Effects of triggering and polyurethane foam on energy absorption of thin-walled circular tubes under the inversion process. J Energy Storage 27:101071

Sarkabiri B, Jahan A, Rezvani MJ (2017) Crashworthiness multi-objective optimization of the thin-walled grooved conical tubes filled with polyurethane foam. J Braz Soc Mech Sci Eng 39(7):2721–2734

Tian K, Zhang Y, Yang F, Zhao Q, Fan H (2020) Enhancing energy absorption of circular tubes under oblique loads through introducing grooves of non-uniform depths. Int J Mech Sci 166:105239

Asanjarani A, Mahdian A, Dibajian S (2020) Comparative analysis of energy absorption behavior of tapered and grooved thin-walled tubes with the various geometry of the cross section. Mech Adv Mater Struct 27(8):633–644

Ahn SH, Jung HS, Kim JS, Son SW (2022) Crashworthiness analysis and shape design optimization of corrugated tubes for railway application. Int J Crashworthiness, pp 1–12

Sadighi A, Azimi MB, Asgari M, Eyvazian A (2021) Crashworthiness of hybrid composite-metal tubes with lateral corrugations in axial and oblique loadings. Int J Crashworthiness, pp 1–17

Zhao Y, Chen L, Li W, Wu Q, Wu L (2023) Improving energy absorption of bidirectional self-locked structures and systems inspired by origami crease. Eur J Mech A/Solids 100:104977

Sun G, Pang T, Xu C, Zheng G, Song J (2017) Energy absorption mechanics for variable thickness thin-walled structures. Thin Walled Struct 118:214–228

Lin Y, Min J, Li Y, Lin J (2019) A thin-walled structure with tailored properties for axial crushing. Int J Mech Sci 157:119–135

Ren X et al (2022) Mechanical properties of foam-filled auxetic circular tubes: Experimental and numerical study. Thin Walled Struct 170:108584

Salehi M, Mirbagheri SMH, Ramiani AJ (2021) Efficient energy absorption of functionally-graded metallic foam-filled tubes under impact loading. Trans Nonferrous Metals Soc China 31(1):92–110

Alkhatib SE, Tarlochan F, Hashem A, Sassi S (2018) Collapse behavior of thin-walled corrugated tapered tubes under oblique impact. Thin Walled Struct 122:510–528

Ahmadi A, Asgari M (2019) Efficient crushable corrugated conical tubes for energy absorption considering axial and oblique loading. Proc Inst Mech Eng C J Mech Eng Sci 233(11):3917–3935

Ghamarian A, Zarei H (2012) Crashworthiness investigation of conical and cylindrical end-capped tubes under quasi-static crash loading. Int J Crashworthiness 17(1):19–28

Zarei H, Ghamarian A (2014) Experimental and numerical crashworthiness investigation of empty and foam-filled thin-walled tubes with shallow spherical caps. Exp Mech 54(2):115–126

Praveen Kumar A, Shrivaathsav S (2019) Influence of forming parameters on the crash performance of capped cylindrical tubes using LS-DYNA follow-on simulations. Int J Interactive Des Manuf (IJIDeM) 13(3):1215–1232

Ghamarian A, Zarei HR, Abadi MT (2011) Experimental and numerical crashworthiness investigation of empty and foam-filled end-capped conical tubes. Thin Walled Struct 49(10):1312–1319

Kumar AP, Mohamed MN, Jusuf A, Dirgantara T, Gunawan L (2018) Axial crash performance of press-formed open and end-capped cylindrical tubes—a comparative analysis. Thin Walled Struct 124:468–488

Rahi A (2019) Experimental and crash-worthiness optimization of end-capped conical tubes under quasi-static and dynamic loading. Mech Adv Mater Struct 26(17):1437–1446

Reddy KY, Kumar AP, Nagarjun J (2020) A computational study on the crushing behaviour of aluminium capped cylindrical tubes subjected to oblique load. Mater Today Proc 27:1923–1927

Jafarian N, Rezvani MJ (2019) Crushing behavior of multi-component conical tubes as energy absorber: A comparative analysis between end-capped and non-capped conical tubes. Eng Struct 178:128–135

Praveen Kumar A, Mohamed MN, Jusuf A, Dirgantara T, Gunawan L (2018) Axial crash performance of press-formed open and end-capped cylindrical tubes–A comparative analysis. Thin Walled Struct 124:468–488

Reyes A, Langseth M, Hopperstad OS (2003) Square aluminum tubes subjected to oblique loading. Int J Impact Eng 28(10):1077–1106

Souzangarzadeh H, Rezvani MJ, Jahan A (2017) Selection of optimum design for conical segmented aluminum tubes as energy absorbers: Application of MULTIMOORA method. Appl Math Model 51:546–560

Russo IM, Cleaver CJ, Allwood JM, Loukaides EG (2020) The influence of part asymmetry on the achievable forming height in multi-pass spinning. J Mater Process Technol 275:116350

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rezvani, M.J., Souzangarzadeh, H. Performance of end-capped multi-segmented conical tubes filled with foam under axial and oblique loads as an energy absorber. J Braz. Soc. Mech. Sci. Eng. 46, 359 (2024). https://doi.org/10.1007/s40430-023-04581-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-023-04581-4